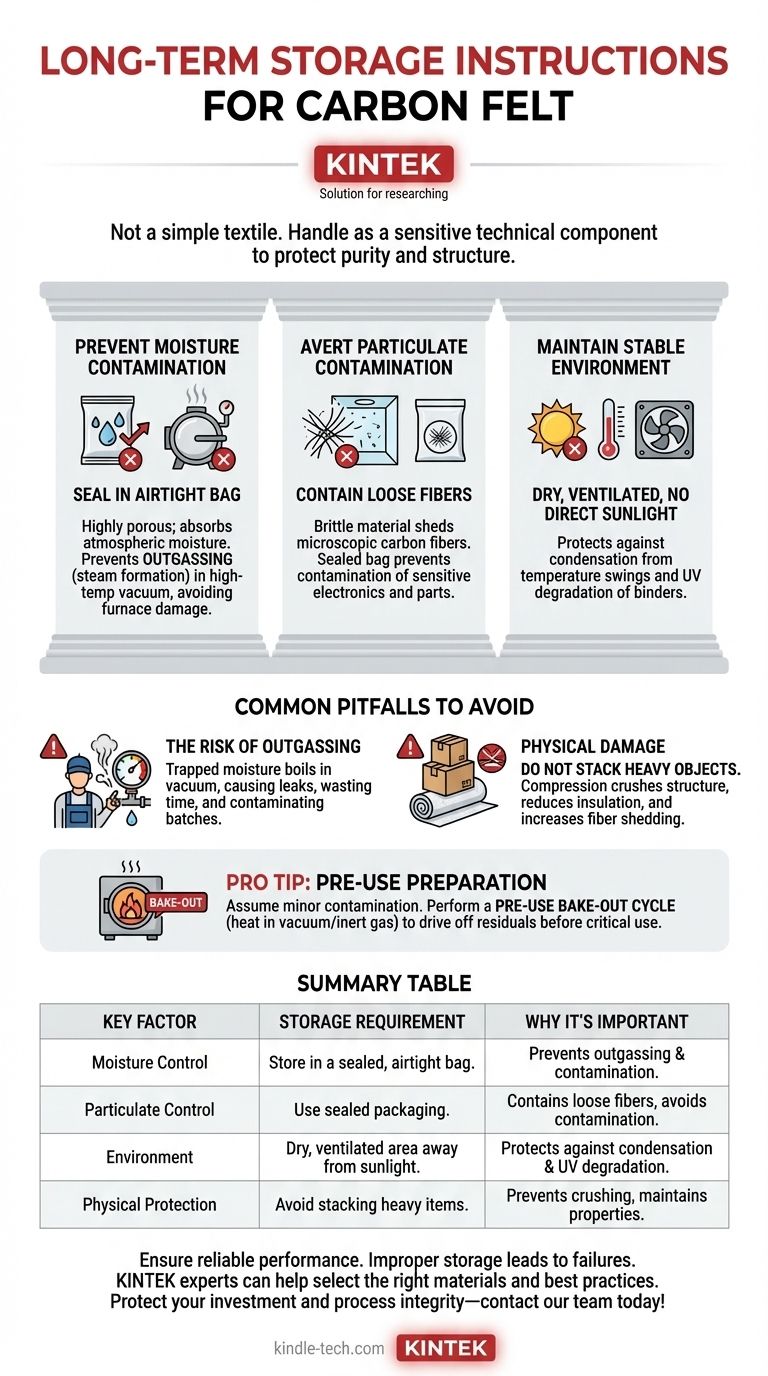

For proper long-term storage, carbon felt must be handled as a sensitive technical component, not a simple textile. It must be packaged in a sealed bag and stored in a controlled environment that is dry, ventilated, and protected from direct sunlight and corrosive substances. This protocol prevents moisture absorption and the shedding of fibers, which are critical for its performance.

The primary goal of storing carbon felt is not merely to keep it organized, but to protect its chemical purity and physical structure. Improper storage introduces contaminants like moisture and particulates that can cause catastrophic failures in high-temperature or high-purity environments.

The Core Principles of Carbon Felt Storage

Understanding why these storage rules exist is key to appreciating their importance. Carbon felt is typically used in applications like vacuum furnaces, fuel cells, and battery systems where purity and stability are paramount.

Preventing Moisture Contamination

Carbon felt is highly porous, giving it an immense surface area that acts like a sponge for atmospheric moisture.

When this damp material is placed in a high-temperature vacuum furnace, the trapped water rapidly turns to steam. This phenomenon, known as outgassing, can ruin the vacuum level and introduce oxygen, which can damage the furnace or the product inside.

Storing the felt in a sealed, airtight bag is the most effective way to isolate it from ambient humidity and prevent this issue.

Averting Particulate Contamination

Carbon felt can be brittle, and handling can cause it to shed microscopic carbon fibers.

These fibers become airborne contaminants. In a cleanroom, they can compromise sensitive electronics. Inside a furnace, they can land on the parts being processed, creating defects.

A sealed bag contains any loose fibers, preventing them from contaminating the storage area or other sensitive components.

Maintaining a Stable Environment

Beyond sealing, the surrounding environment provides a second layer of defense.

Storing the sealed material in a dry, ventilated area protects against condensation that might occur with temperature swings. It also ensures that if a bag's seal is compromised, the felt is not immediately exposed to a humid environment.

Protection from direct sunlight is also a best practice. While carbon is highly stable, ultraviolet (UV) radiation can degrade any binders or sizing agents within the felt over time.

Common Pitfalls to Avoid

Failing to adhere to these protocols can lead to significant and costly problems that only become apparent during use.

The Risk of Outgassing

The most common failure mode from improper storage is outgassing. A technician might spend hours trying to diagnose a vacuum leak, only to find the issue was water vapor boiling out of the new insulation.

This wastes time, energy, and can contaminate an entire process batch, leading to significant financial loss.

The Problem of Physical Damage

Do not store heavy objects on top of carbon felt, even when it is bagged.

Compression can crush the delicate fiber structure, reducing its insulating properties. It also increases the likelihood of the material becoming brittle and shedding more fibers upon handling.

Forgetting Pre-Use Preparation

Even with perfect storage, it is a professional best practice to assume some minor contamination has occurred.

For highly sensitive applications, performing a pre-use bake-out cycle on the carbon felt is recommended. This involves heating the material in a vacuum or inert gas environment to drive off any residual moisture or volatile compounds before it is used in a critical process.

Making the Right Choice for Your Goal

Your storage strategy should align with the sensitivity of your application.

- If your primary focus is high-vacuum or semiconductor applications: Your top priority is preventing moisture and particulate contamination, so vacuum sealing the felt is the gold standard.

- If your primary focus is general high-temperature insulation: Meticulously sealing the material in a heavy-duty, moisture-barrier bag to prevent moisture absorption and physical damage is sufficient.

- If the felt has been exposed to ambient air for an extended period: Always perform a pre-use bake-out cycle to drive off any absorbed contaminants before introducing it into your process.

Proper storage is the first, most critical step in ensuring the reliability and performance of your entire system.

Summary Table:

| Key Factor | Storage Requirement | Why It's Important |

|---|---|---|

| Moisture Control | Store in a sealed, airtight bag. | Prevents outgassing in vacuum furnaces and contamination. |

| Particulate Control | Use sealed packaging. | Contains loose fibers to avoid contaminating sensitive environments. |

| Environment | Keep in a dry, ventilated area away from sunlight. | Protects against condensation and UV degradation. |

| Physical Protection | Avoid stacking heavy items on top. | Prevents crushing the fiber structure and maintains insulation properties. |

Ensure your carbon felt performs reliably. Improper storage can lead to costly process failures and contamination. KINTEK specializes in high-purity lab equipment and consumables, including carbon felt designed for demanding applications like vacuum furnaces and fuel cells. Our experts can help you select the right materials and implement best practices for storage and handling.

Protect your investment and process integrity—contact our team today for a consultation!

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Graphite Vacuum Continuous Graphitization Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the typical physical specifications for glassy carbon sheets? Unlock Superior Performance for Your Lab

- What are the fundamental characteristics of glassy carbon? Discover its Unique Synergy of Properties

- What is the proper procedure for cleaning a glassy carbon sheet after use? A Definitive Guide to Ensure Reliable Results

- What is the porosity of an RVC glassy carbon sheet? Understanding the Critical Difference Between PPI and Porosity

- Why is a glassy carbon disc electrode an indispensable consumable? Ensure Reliable Catalyst Evaluation Today