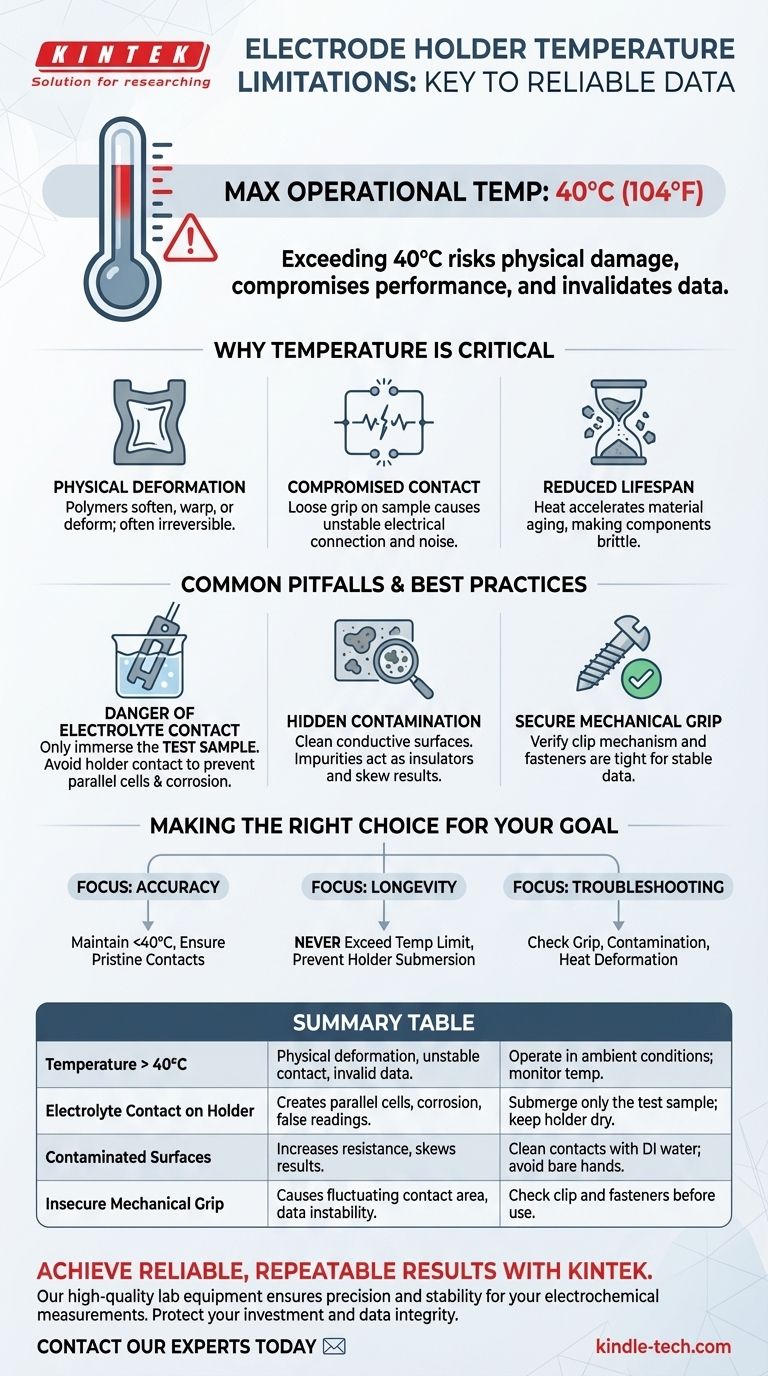

For reliable and accurate electrochemical measurements, the operational temperature of a standard electrode holder is a critical limiting factor. These devices are designed to function at ambient temperatures, which should ideally not exceed 40°C (104°F). Exceeding this thermal threshold risks physical damage to the holder, compromises its performance, and can ultimately invalidate your experimental data.

While the explicit temperature limit is 40°C, the deeper principle is that an electrode holder's stability—both physical and electrical—is paramount. Heat is just one of several factors, including contamination and improper submersion, that can compromise this stability and render your results unreliable.

Why Temperature is a Critical Limiter

An electrode holder is more than just a simple clip; it is a precision tool. Its materials are chosen for electrical insulation and chemical resistance under specific conditions, and high temperatures push them beyond their designed operational window.

The Risk of Physical Deformation

Most electrode holders incorporate polymers and insulating materials that can soften, warp, or deform when exposed to elevated temperatures. This physical change is often irreversible and can permanently damage the device.

Compromised Electrical Contact

If the holder deforms, the precision grip on the test sample can loosen. This leads to an inconsistent and unstable electrical connection, which introduces significant noise and error into sensitive electrochemical measurements like impedance or corrosion potential.

Reduced Material Lifespan

Heat acts as a catalyst for material aging. Continuous exposure to temperatures above the recommended limit will degrade the holder's components, making them brittle and shortening the effective service life of the tool.

Common Pitfalls and Best Practices

Beyond temperature, several other operational errors can compromise your experiment. Understanding these is just as crucial as managing the thermal environment.

The Danger of Electrolyte Contact

It is absolutely critical that only the test sample comes into contact with the electrolyte solution. If any other part of the electrode holder—such as the clip or shaft—is submerged, it can create a parallel electrochemical cell, leading to false readings and corrosion of the holder itself.

The Hidden Variable of Contamination

The conductive surfaces of both the holder and the sample must be perfectly clean. Grease, oxides, or other impurities act as an insulating layer, increasing resistance and skewing the results. If the conductive sheet is dirty, rinse it with deionized water and avoid touching the sample with bare hands.

The Importance of a Secure Mechanical Grip

Before every use, perform a quick mechanical check. Ensure the clip mechanism opens and closes properly and that all fastening components are tight. A loose sample can lead to a fluctuating contact area, which will appear as instability in your data.

Making the Right Choice for Your Goal

To ensure your measurements are sound, integrate these principles into your experimental procedure. Your specific focus will determine which factors to prioritize.

- If your primary focus is data accuracy: Strictly maintain the ambient temperature below 40°C and ensure pristine cleanliness of all electrical contact points.

- If your primary focus is equipment longevity: Never exceed the temperature limit and always prevent the holder body from making contact with the electrolyte to avoid corrosion.

- If you are troubleshooting inconsistent results: Systematically check for a secure sample grip, signs of contamination, and any visible heat-induced deformation on the holder.

Controlling these variables is fundamental to achieving trustworthy and repeatable electrochemical data.

Summary Table:

| Key Limitation | Critical Impact | Best Practice |

|---|---|---|

| Temperature > 40°C (104°F) | Physical deformation, unstable electrical contact, invalid data. | Operate in ambient conditions; monitor temperature closely. |

| Electrolyte Contact on Holder | Creates parallel cells, causes corrosion, leads to false readings. | Submerge only the test sample; keep holder body dry. |

| Contaminated Surfaces | Increases electrical resistance, skews results. | Clean contacts with deionized water; avoid touching with bare hands. |

| Insecure Mechanical Grip | Causes fluctuating contact area, data instability. | Check clip mechanism and fasteners for tightness before each use. |

Achieve reliable, repeatable results with the right lab equipment.

Your electrochemical measurements depend on the precision and stability of your tools. At KINTEK, we specialize in high-quality lab equipment and consumables designed for accuracy and durability. Whether you are setting up a new lab or optimizing your current processes, our expertise ensures you have the right solutions to maintain precise temperature control and avoid common experimental pitfalls.

Let us help you protect your investment and ensure your data's integrity. Contact our experts today to discuss your specific laboratory needs and discover how KINTEK can support your research goals.

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Customizable XRD Sample Holders for Diverse Research Applications

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Button Battery Case for Battery Lab Applications

People Also Ask

- Why is high-purity PTFE selected as the sample holder for zirconium alloy corrosion tests? Gain Unmatched Data Accuracy

- How does a custom PTFE electrode holder contribute to the accuracy of immersion tests? Ensure Precise Steel Analysis

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- What materials are the sample holders made of? Engineered with PTFE and PEEK for Purity