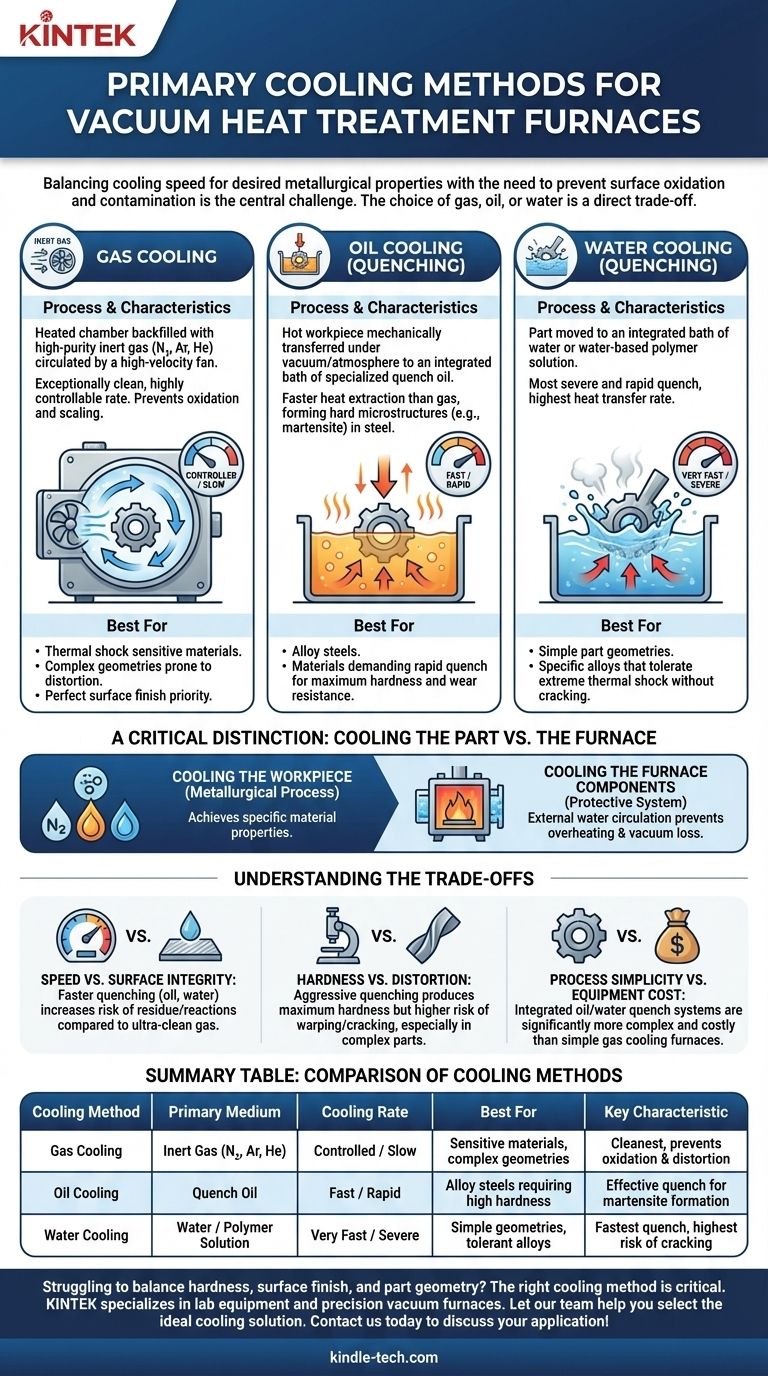

The three primary methods for cooling a workpiece in a vacuum heat treatment furnace are gas cooling, oil cooling, and water cooling. Each method involves a different medium and cooling rate, selected specifically to achieve the desired metallurgical properties in the finished part while preserving the pristine, oxide-free surface created by the vacuum environment.

The central challenge in vacuum furnace cooling is balancing the need for a specific cooling speed—which dictates the material's final properties—with the mandate to prevent surface oxidation and contamination. Your choice of gas, oil, or water is a direct trade-off between these factors.

The Role of Cooling in Vacuum Heat Treatment

Why Cooling Rate is Critical

The rate at which a metal part cools after heating determines its final microstructure. This internal structure dictates crucial mechanical properties like hardness, toughness, and ductility.

Processes like quenching (rapid cooling) are designed to "lock in" a desirable microstructure, while slower processes like annealing create a softer, more workable state. The cooling method is not an afterthought; it is a fundamental part of the heat treatment recipe.

Preserving the Vacuum Advantage

The primary benefit of using a vacuum furnace is the complete absence of air, which prevents oxidation, scaling, and discoloration.

This means parts emerge from the furnace clean and often ready for immediate use without secondary cleaning operations. The chosen cooling method must maintain this high level of surface integrity.

A Breakdown of the Core Cooling Methods

Gas Cooling

This is the most common method for parts that require controlled cooling without the risk of contamination. The process involves backfilling the heated vacuum chamber with a high-purity inert gas.

- Process: After the heating cycle, a high-velocity fan circulates an inert gas like nitrogen, argon, or helium through the chamber and over the parts.

- Characteristics: Gas cooling is exceptionally clean and offers a highly controllable cooling rate, which can be adjusted by changing the gas pressure and fan speed.

- Best For: Materials sensitive to thermal shock, complex geometries prone to distortion, and applications where maintaining a perfect surface finish is the highest priority.

Oil Cooling (Quenching)

For many alloy steels, gas cooling is not fast enough to achieve the required hardness. In these cases, oil quenching is used.

- Process: The hot workpiece is mechanically transferred from the heating chamber to a separate, integrated chamber containing a bath of specialized quench oil, all while maintaining a vacuum or controlled atmosphere.

- Characteristics: Oil provides a much faster rate of heat extraction than gas, enabling the formation of hard microstructures like martensite in steel.

- Best For: Alloy steels and other materials that demand a rapid quench to achieve maximum hardness and wear resistance.

Water Cooling (Quenching)

Water provides the most severe and rapid quench possible, but its use is less common due to the high risk of part distortion or cracking.

- Process: Similar to oil quenching, the part is moved to an integrated bath of water or a water-based polymer solution.

- Characteristics: Water offers the fastest heat transfer, resulting in the highest possible hardness for certain materials.

- Best For: Simple part geometries and specific alloys that can withstand extreme thermal shock without cracking.

A Critical Distinction: Cooling the Part vs. the Furnace

It is essential to distinguish between cooling the workpiece and cooling the furnace itself. While they can both use water, their functions are entirely different.

Cooling the Workpiece

This is the metallurgical process discussed above, using gas, oil, or water to achieve specific material properties.

Cooling the Furnace Components

Every vacuum furnace has an external water-cooling system for its structural components. This system circulates water through jackets in the furnace shell, door, and power feedthroughs. Its purpose is purely protective: to prevent the furnace walls and critical rubber seals from overheating and failing, which would cause a loss of vacuum.

Understanding the Trade-offs

Speed vs. Surface Integrity

Faster quenching methods like oil and water are more effective at hardening but carry a higher risk of leaving residue or causing surface reactions compared to ultra-clean inert gas.

Hardness vs. Distortion

The more aggressive the quench, the greater the internal stresses placed on the material. While water quenching can produce maximum hardness, it also creates the highest risk of warping or cracking, especially in parts with intricate designs or sharp corners.

Process Simplicity vs. Equipment Cost

Furnaces designed only for gas cooling are generally simpler and less expensive. Furnaces with integrated oil or water quench capabilities are multi-chamber systems that are significantly more complex and costly to build and maintain.

Making the Right Choice for Your Application

Your selection must align directly with the material being treated and your end goal.

- If your primary focus is surface cleanliness and minimizing distortion: Gas cooling is the most reliable choice, protecting part geometry and finish.

- If your primary focus is achieving maximum hardness in most alloy steels: Oil quenching provides the rapid cooling rate required for these materials.

- If your primary focus is processing simple carbon steels or alloys that tolerate extreme thermal shock: Water quenching offers the fastest possible cooling cycle.

Ultimately, selecting the correct cooling method is how you translate the theoretical benefits of vacuum heat treatment into a reliable, high-quality finished product.

Summary Table:

| Cooling Method | Primary Medium | Cooling Rate | Best For | Key Characteristic |

|---|---|---|---|---|

| Gas Cooling | Inert Gas (N₂, Ar, He) | Controlled / Slow | Sensitive materials, complex geometries | Cleanest, prevents oxidation & distortion |

| Oil Cooling | Quench Oil | Fast / Rapid | Alloy steels requiring high hardness | Effective quench for martensite formation |

| Water Cooling | Water / Polymer Solution | Very Fast / Severe | Simple geometries, tolerant alloys | Fastest quench, highest risk of cracking |

Struggling to balance hardness, surface finish, and part geometry in your heat treatment process? The right cooling method is critical. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision vacuum furnaces and expert guidance. Let our team help you select the ideal cooling solution—gas, oil, or water—to achieve your specific metallurgical goals and protect your part integrity. Contact us today to discuss your application!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does temperature affect vacuum pressure? Master the Key to System Control

- What is the normal temperature for a furnace? Unlock the Key to Efficient Home Heating

- What role does a vacuum drying oven play in the calcium thermal reduction process? Preserve High-Purity Metal Powders

- What are the factors affecting the sintering process? Master the 5 Key Factors for Perfect Sintering

- What is the typical temperature range for plasma nitriding? Optimize for Speed, Depth, or Precision

- Why is a vacuum drying oven required for NCM-811 cathode powder? Essential Pretreatment for Sulfide Batteries

- How does vacuum arc remelting work? Achieve Ultra-Clean, High-Performance Metal Alloys

- What role does a high-temperature experimental furnace play in the carbonization process of Magnetic Composite Carbon?