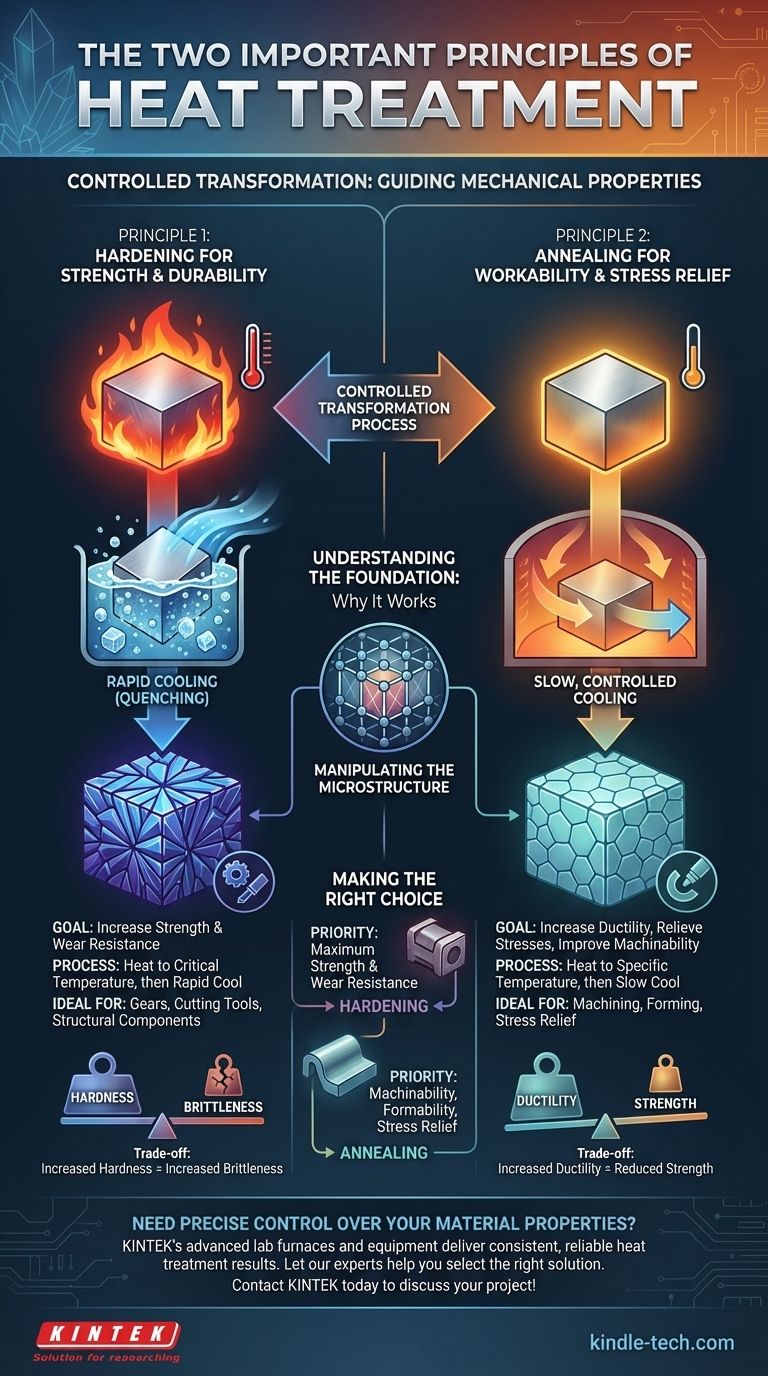

At its core, heat treatment is a process of controlled transformation. The two fundamental and opposing principles guiding this process are hardening and annealing. Hardening is used to increase a metal's strength and resistance to wear, while annealing is used to make it softer, more ductile, and easier to shape or machine. These principles represent the two primary directions in which a material's mechanical properties can be deliberately altered.

The purpose of heat treatment is to intentionally change a metal's internal microstructure. The principles of hardening and annealing are simply the two primary goals of this manipulation: either to increase strength and durability or to enhance softness and workability.

The Foundation: Why Heat Treatment Works

Heat treatment is a precise metallurgical science. Its effectiveness hinges on understanding how temperature and time can fundamentally change a material at a microscopic level.

Manipulating the Microstructure

The properties of a metal—its hardness, toughness, and ductility—are determined by its internal crystal structure, known as its microstructure. By applying heat, we can dissolve and reform these crystals into new arrangements.

The Role of Controlled Heating and Cooling

The specific outcome of the treatment is dictated by the precise temperatures used and, most critically, the rate of cooling. A rapid cool (quenching) and a slow cool will produce vastly different microstructures and, therefore, vastly different material properties, even in the same piece of metal.

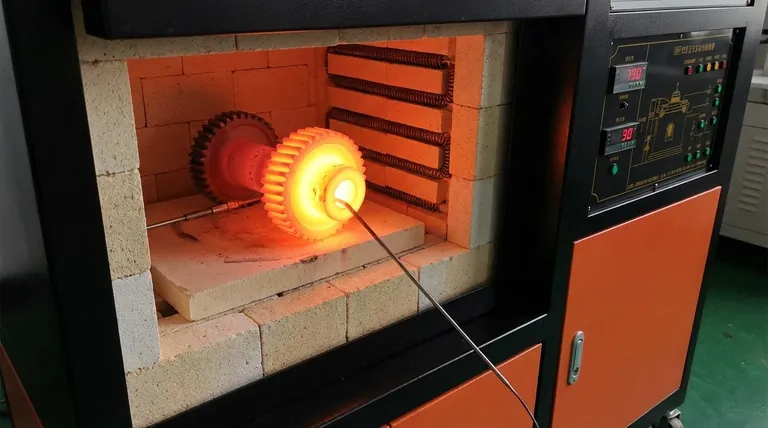

Principle 1: Hardening for Strength and Durability

Hardening processes are designed to maximize a material's resistance to deformation, indentation, and abrasion. This is a critical step for parts that will be under significant stress or subject to wear.

The Goal of Hardening

The primary objective is to make the metal stronger and more wear-resistant. This is essential for components like gears, cutting tools, and structural steel, where failure is not an option.

How It's Achieved

Generally, hardening involves heating the metal to a critical temperature where its crystal structure changes. It is then cooled very rapidly, often by quenching it in water, oil, or air. This rapid cooling "traps" the microstructure in a very hard but brittle state.

Principle 2: Annealing for Workability and Stress Relief

Annealing represents the opposite objective. Its purpose is to return the metal to its softest, least-stressed state, making it more predictable and cooperative for subsequent manufacturing steps.

The Goal of Annealing

The key objectives are to increase ductility (the ability to be shaped without breaking), relieve internal stresses from previous processes like welding, and improve its machinability.

How It's Achieved

Annealing involves heating the metal to a specific temperature and then cooling it very slowly. This slow, controlled cooling allows the microstructure to re-form in a highly ordered and low-energy state, which results in a softer and less brittle material.

Understanding the Trade-offs

Neither hardening nor annealing is inherently superior; they are tools used to achieve a specific engineering goal. The choice always involves a compromise between competing properties.

The Hardness vs. Brittleness Compromise

A fundamental trade-off in metallurgy is that as a material gets harder, it almost always becomes more brittle. A fully hardened steel part is incredibly strong but may shatter like glass if subjected to a sharp impact.

The Strength vs. Ductility Balance

Conversely, making a material more ductile through annealing invariably reduces its overall strength and hardness. An annealed part is easy to form and machine but would fail quickly in a high-stress application.

Making the Right Choice for Your Application

Selecting the correct heat treatment principle depends entirely on the intended function of the final component.

- If your primary focus is maximum strength and wear resistance: You will prioritize hardening processes, accepting the trade-off of reduced ductility.

- If your primary focus is machinability, formability, or stress relief: You will use annealing processes to make the material softer and easier to work with.

Ultimately, mastering heat treatment means understanding how to apply these two opposing principles to achieve the precise material properties your design demands.

Summary Table:

| Principle | Primary Goal | Key Process | Ideal For |

|---|---|---|---|

| Hardening | Increase strength and wear resistance | Heat to critical temperature, then rapid cooling (quenching) | Gears, cutting tools, structural components |

| Annealing | Improve ductility, relieve stress, and enhance workability | Heat to specific temperature, then slow, controlled cooling | Machining, shaping, stress relief after welding |

Need precise control over your material properties? KINTEK's advanced lab furnaces and equipment are designed to deliver consistent, reliable heat treatment results—whether you're hardening for durability or annealing for workability. Let our experts help you select the right solution for your laboratory's specific needs. Contact KINTEL today to discuss your project!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How can I increase my sputtering rate? Boost Deposition Speed with These Key Techniques

- What are the safety precautions for nanoparticles? A Guide to Minimizing Inhalation and Exposure Risks

- Why KBr is used for FTIR? Achieve Clear, Accurate Solid-Sample Analysis

- What are the characteristics of sintering? Master Controlled Porosity and High-Performance Materials

- What is the primary function of high-performance homogenizers for SAPO-34 MMMs? Ensure Superior Gas Separation Efficiency

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion

- What are the specifications for biomass pellets? Key Metrics for Efficient, Clean Heat

- What are the benefits of biomass pellets? A Sustainable, Cost-Effective Fuel Alternative