At its core, a laboratory oven is used for two primary functions: drying samples and glassware, and sterilizing heat-stable equipment. It accomplishes this using controlled convection heat, which circulates hot air to maintain a uniform temperature and gently remove moisture without the damaging effects of direct radiant heat.

A laboratory oven is not simply for heating. It is a precision instrument designed for removing moisture and decontaminating materials through controlled, uniform air circulation, ensuring sample integrity and repeatable results.

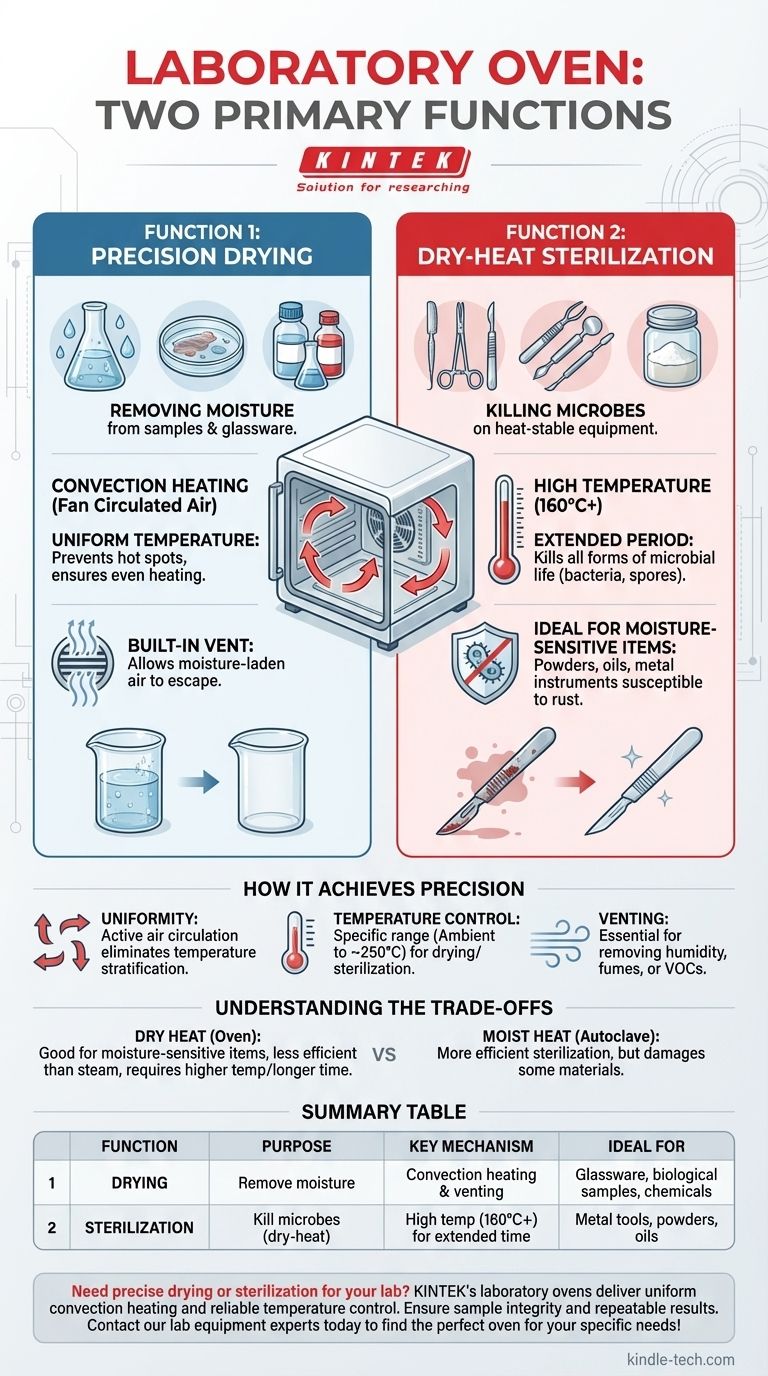

The Core Functions: Drying and Sterilization

While an oven may seem like a simple device, its value in a laboratory comes from its ability to perform two critical tasks with high precision and reliability.

Function 1: Precision Drying

The most common use of a laboratory oven is for drying. This involves removing residual moisture from lab equipment or dehydrating biological samples.

The process relies on convection heating, where a fan circulates hot air throughout the chamber. This ensures every surface is heated evenly, preventing "hot spots" that could damage a sensitive sample or crack glassware.

A built-in vent allows the moisture-laden air to escape, which is essential for efficient and thorough drying.

Function 2: Dry-Heat Sterilization

The second major function is sterilization. By maintaining a high temperature (typically 160°C or higher for an extended period), the oven kills all forms of microbial life, including bacteria and spores.

This method is crucial for sterilizing items that cannot be exposed to the moisture of an autoclave, such as powders, oils, and certain metal instruments that are susceptible to rust.

How a Laboratory Oven Achieves Precision

The difference between a lab oven and a standard kitchen oven lies in its design for control and uniformity. This precision is what makes it a scientific instrument.

The Role of Convection

Uniformity is paramount in scientific work. By actively circulating air, a convection oven eliminates the temperature stratification found in simpler static ovens, ensuring that an experiment or process can be repeated under the exact same conditions.

Temperature Control and Range

Laboratory ovens operate within a specific temperature range, typically from just above ambient up to around 250°C. This range is ideal for drying and sterilization but is distinct from a furnace, which reaches much higher temperatures for processes like ashing.

The Importance of Venting

The oven's vent is a critical feature. For drying, it allows humidity to be removed from the chamber. For other processes, it safely removes fumes or volatile organic compounds (VOCs) that may be released from a sample during heating.

Understanding the Trade-offs

While effective, a laboratory oven is not the right tool for every heating task. Its primary limitation is that it uses dry heat, which has different properties than the moist heat used in an autoclave.

When Dry Heat is Essential

Dry heat is the method of choice for any material that would be damaged by moisture. This includes sharp instruments that could be dulled by rust, as well as anhydrous powders or oils that must remain free of water.

The Limits of a Lab Oven

Dry-heat sterilization is less efficient than steam sterilization. It requires significantly higher temperatures and much longer exposure times to achieve the same level of sterility. Furthermore, it is unsuitable for heat-sensitive materials like plastics or for sterilizing liquids.

Making the Right Choice for Your Task

Selecting the correct heating method is fundamental to good laboratory practice. Your choice depends entirely on your material and your goal.

- If your primary focus is removing moisture: Use a laboratory oven for its controlled convection heating to gently and thoroughly dry glassware, biological specimens, or chemical samples.

- If your primary focus is decontaminating heat-stable equipment: Use a laboratory oven for dry-heat sterilization, especially for items like metal instruments or powders that cannot be exposed to steam.

Ultimately, understanding these core functions allows you to use a laboratory oven not just as a heater, but as a precise tool for ensuring the integrity and safety of your work.

Summary Table:

| Function | Purpose | Key Mechanism | Ideal For |

|---|---|---|---|

| Drying | Remove moisture | Convection heating & venting | Glassware, biological samples, chemicals |

| Sterilization | Kill microbes (dry-heat) | High temp (160°C+) for extended time | Metal tools, powders, oils (moisture-sensitive items) |

Need precise drying or sterilization for your lab?

KINTEK's laboratory ovens deliver the uniform convection heating and reliable temperature control your work demands. Ensure sample integrity and repeatable results for your drying and sterilization processes.

Contact our lab equipment experts today to find the perfect oven for your specific needs!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

People Also Ask

- Have other labs successfully stored samples at -70°C? Proven Long-Term Preservation for Biological Materials

- What is the function of a laboratory filtration system in hydrothermal liquefaction? Maximize Biomass Yield

- Why do we need to use properly some of the laboratory apparatus in the laboratory? The Foundation of Safe and Accurate Science

- What is a target in a sputtering process? The Source of Your Thin Film Coating

- What temperature is approximately equal to sintering? A Guide Based on Your Material's Melting Point

- What are the disadvantages of powder metallurgy? Key Limitations in Strength and Size

- What is coating deposition? Engineer Superior Surface Properties for Your Materials

- What is the physical Vapour deposition method? A Guide to High-Performance Thin Films