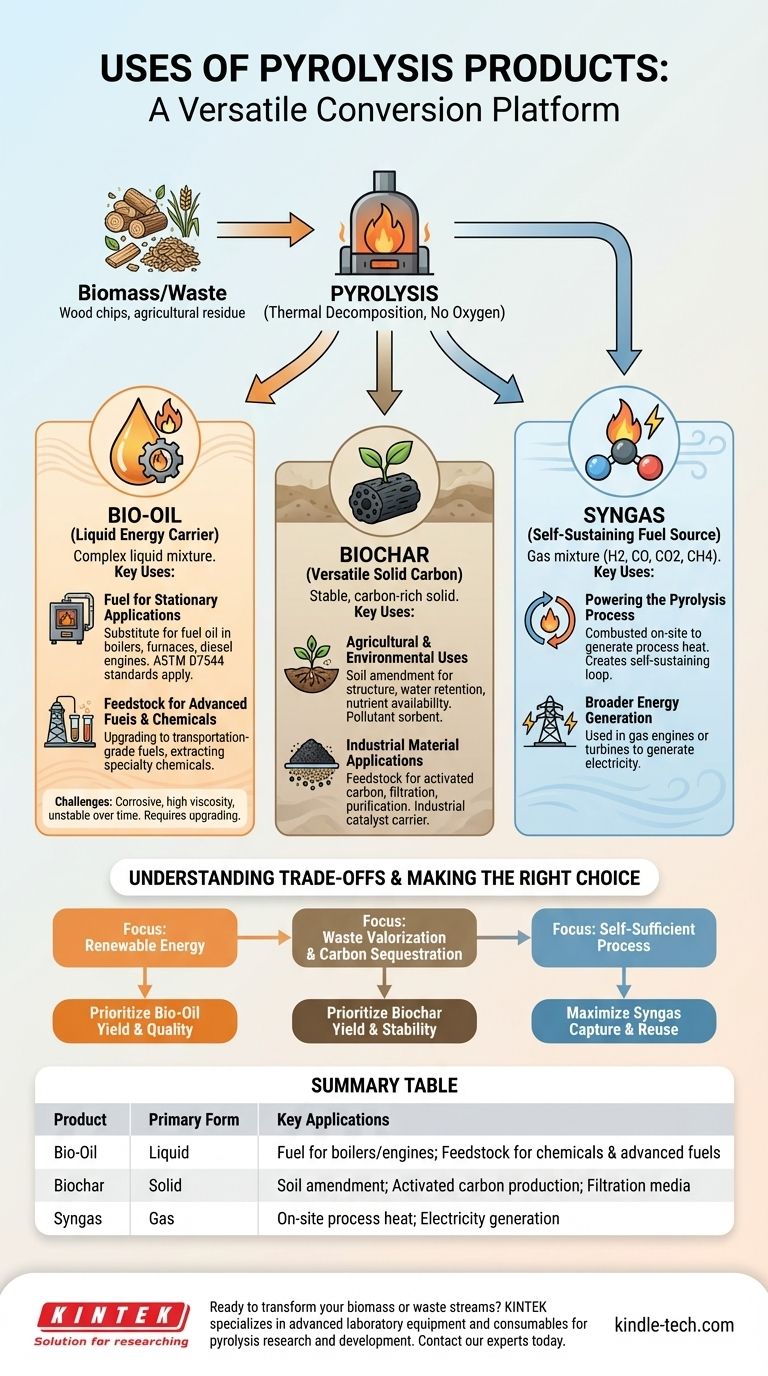

The products of pyrolysis are not waste; they are a diverse slate of valuable outputs created by thermally decomposing materials like biomass in the absence of oxygen. The process yields three primary products: a liquid known as bio-oil, a solid called biochar, and a combustible gas mixture called syngas. Bio-oil is used as a fuel for heating and power, biochar serves as a potent soil amendment and carbon material, and syngas is often used to provide energy back to the pyrolysis process itself.

Pyrolysis is best understood as a versatile conversion platform, not a single-output process. The true value lies in its ability to transform low-value biomass or waste streams into a portfolio of useful products for energy, agriculture, and materials science.

Bio-Oil: The Liquid Energy Carrier

Bio-oil, also known as pyrolysis oil, is a complex liquid mixture that represents the condensed volatile components from the pyrolysis reaction. Its applications are primarily centered around energy and chemical production.

Fuel for Stationary Applications

The most direct use of bio-oil is as a substitute for conventional fuel oil in stationary applications like industrial boilers, furnaces, and certain diesel engines or power plants.

Its use in these applications is governed by standards like ASTM D7544, ensuring it meets specific quality criteria for combustion.

Feedstock for Advanced Fuels and Chemicals

While it can be burned directly, bio-oil's higher value lies in its potential as a feedstock. Through upgrading and refining processes, it can be converted into more conventional hydrocarbon fuels, such as transportation-grade gasoline or diesel.

It also contains a variety of chemical compounds that can be extracted to produce specialty chemicals and other valuable materials.

Biochar: The Versatile Solid Carbon

Biochar is the stable, carbon-rich solid that remains after pyrolysis. It is more than just charcoal; its porous structure gives it a wide range of uses in both agriculture and industry.

Agricultural and Environmental Uses

As a soil amendment, biochar improves soil structure, water retention, and nutrient availability, enhancing agricultural productivity.

Its porous nature makes it an excellent sorbent for trapping pollutants, making it useful for environmental remediation efforts.

Industrial Material Applications

Biochar serves as a key feedstock for producing activated carbon, a critical material used in filtration and purification systems.

It can also be used as a general-purpose carbon material or as a stable carrier for industrial catalysts.

Syngas: The Self-Sustaining Fuel Source

Syngas is the mix of non-condensable gases produced during pyrolysis, primarily composed of hydrogen, carbon monoxide, carbon dioxide, and methane.

Powering the Pyrolysis Process

In many pyrolysis systems, the syngas is captured and combusted on-site to generate the heat required for the pyrolysis reaction itself.

This creates a highly efficient, self-sustaining loop that significantly reduces the external energy input needed to run the system.

Broader Energy Generation

If produced in excess, syngas can be used in gas engines or turbines to generate electricity, contributing to the overall energy output of the facility.

Understanding the Trade-offs and Challenges

While the products of pyrolysis have significant potential, their practical, industrial-scale application faces several hurdles that require objective consideration.

The Instability of Bio-Oil

Raw bio-oil presents challenges. It is often corrosive to standard pipes and engines, has a high viscosity, and can be chemically unstable over time, which complicates storage and transport.

These issues are a primary reason why bio-oil often requires upgrading before it can be used widely as a drop-in fuel.

Feedstock Determines Product Quality

The exact composition and quality of the bio-oil, biochar, and syngas are not fixed. They depend heavily on the type of feedstock (e.g., wood waste vs. agricultural residue) and the specific process conditions (e.g., temperature and heating rate).

This variability means that a process optimized for one type of waste may not be suitable for another, requiring careful tuning and control.

Making the Right Choice for Your Goal

The applications you prioritize will determine how you approach the pyrolysis process.

- If your primary focus is renewable energy: Prioritize optimizing the yield and quality of bio-oil for direct combustion or for upgrading into liquid transportation fuels.

- If your primary focus is waste valorization and carbon sequestration: Concentrate on producing high-quality, stable biochar to lock carbon into a useful form for agriculture or materials.

- If your primary focus is creating a self-sufficient process: Maximize the capture and reuse of syngas to power the pyrolysis unit, significantly reducing external operational costs.

Ultimately, leveraging pyrolysis effectively means treating it as a tunable system to convert a specific feedstock into the most valuable product slate for your strategic goal.

Summary Table:

| Product | Primary Form | Key Applications |

|---|---|---|

| Bio-Oil | Liquid | Fuel for boilers/engines; Feedstock for chemicals & advanced fuels |

| Biochar | Solid | Soil amendment; Activated carbon production; Filtration media |

| Syngas | Gas | On-site process heat; Electricity generation |

Ready to transform your biomass or waste streams into valuable products?

KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and development. Whether you're optimizing bio-oil yields, characterizing biochar, or developing efficient syngas utilization, our solutions help you achieve your goals in renewable energy, waste valorization, and materials science.

Contact our experts today to discuss how we can support your pyrolysis projects and help you unlock the full potential of your feedstocks.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs