In professional contexts, there is no single "other name" for a melting furnace. The correct term depends entirely on the specific process, the technology used to generate heat, and the material being melted. While a general term might be a "foundry furnace," more precise names like "induction furnace" or "electric arc furnace" are used to describe its function and design.

The term "melting furnace" is a broad descriptor. The specific, technically accurate name is determined by its heating method (e.g., induction, arc) or its chemical process (e.g., smelting), which reveals its true function and capabilities.

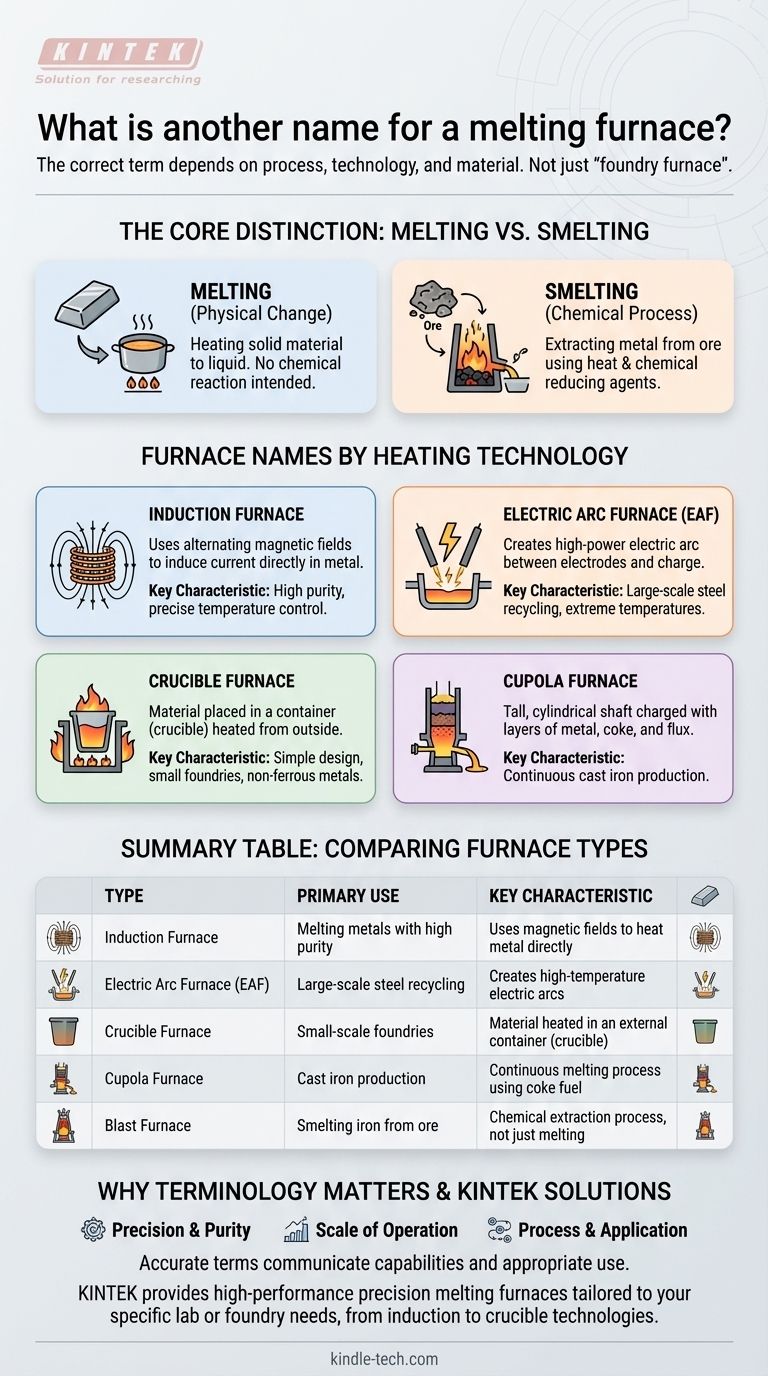

The Core Distinction: Melting vs. Smelting

Before exploring furnace types, it's crucial to understand the difference between two often-confused processes. This distinction is fundamental to using the correct terminology.

What is Melting?

Melting is a physical change of state. It is simply the process of heating a solid material, like a metal ingot, until it becomes a liquid. No chemical reaction is intended to happen.

What is Smelting?

Smelting is a chemical process used to extract a metal from its ore. It involves heating the ore to high temperatures with a chemical reducing agent, like carbon. Smelting includes melting as the extracted metal becomes liquid, but its primary purpose is chemical transformation.

A blast furnace used to make iron from ore is a smelting furnace. A furnace used to melt down aluminum scrap for recycling is a melting furnace.

Furnace Names Based on Heating Technology

The most common way to name a melting furnace in an engineering or foundry context is by the technology it uses to generate heat. This is the most precise and descriptive method.

Induction Furnace

This furnace uses alternating magnetic fields to induce an electric current directly within the metal charge. The metal's own electrical resistance generates intense, clean, and highly controllable heat.

Electric Arc Furnace (EAF)

An EAF melts metal by creating a high-power electric arc between graphite electrodes and the metal charge. This process generates extreme temperatures and is commonly used for recycling steel scrap on a massive scale.

Crucible Furnace

This is one of the simplest designs. The material is placed inside a container called a crucible, which is then heated from the outside by a flame (gas or oil) or electric elements. They are common in smaller foundries and for non-ferrous metals.

Cupola Furnace

A cupola is a tall, cylindrical shaft furnace that has been a workhorse for producing cast iron for centuries. It is charged with layers of metal, coke (fuel), and limestone (a flux) from the top and provides a continuous flow of molten metal from the bottom.

Why the Right Terminology Matters

Using the correct name is not just academic. It communicates critical information about the furnace's capabilities, scale, and appropriate use.

Precision and Purity

An induction furnace offers very high purity and precise temperature control, making it ideal for specialty alloys. A cupola furnace, which burns fuel in direct contact with the metal, is less controlled and introduces chemical changes, making it suitable for specific grades of cast iron.

Scale of Operation

The term "electric arc furnace" immediately implies a large-scale industrial operation, often melting over 100 tons of steel at a time. In contrast, a "crucible furnace" can be small enough for a hobbyist's workshop.

Process and Application

Calling something a "blast furnace" specifically signifies that its purpose is smelting iron ore. Referring to a "glass furnace" or "kiln" indicates it's designed for entirely different materials and temperature profiles than a metal furnace.

How to Apply This to Your Goal

Use the context of your work to select the most accurate and effective term.

- If your primary focus is general metal casting: "Foundry furnace" is a suitable and widely understood term.

- If you are extracting raw metal from ore: The correct term is "smelting furnace," with "blast furnace" being the most common type for iron.

- If you need to be technically precise for engineering or purchasing: Always use the name based on the heating technology, such as "induction furnace" or "gas-fired crucible furnace."

- If you are working with precious metals: Terms like "gold melting furnace" or "silver melting furnace" are common, as these are often small, specialized electric resistance or induction units.

Using the right name demonstrates a clear understanding of the process, technology, and purpose behind the equipment.

Summary Table:

| Furnace Type | Primary Use | Key Characteristic |

|---|---|---|

| Induction Furnace | Melting metals with high purity | Uses magnetic fields to heat metal directly |

| Electric Arc Furnace (EAF) | Large-scale steel recycling | Creates high-temperature electric arcs |

| Crucible Furnace | Small-scale foundries, non-ferrous metals | Material heated in an external container (crucible) |

| Cupola Furnace | Cast iron production | Continuous melting process using coke fuel |

| Blast Furnace | Smelting iron from ore | Chemical extraction process, not just melting |

Need the Right Furnace for Your Lab or Foundry?

Choosing the correct melting furnace is critical for the success of your process, whether you're working with precious metals, recycling scrap, or developing new alloys. KINTEK specializes in providing high-performance lab equipment, including precision melting furnaces tailored to your specific material and application needs.

We can help you:

- Achieve superior temperature control and purity for specialty alloys.

- Scale your operations with reliable and efficient melting solutions.

- Select the ideal technology—from induction to crucible furnaces—for your exact requirements.

Let's discuss your project. Contact our experts today to find the perfect melting furnace for your laboratory or production needs.

Visual Guide

Related Products

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What are the advantages of induction furnace? Achieve Superior Metal Quality & Efficiency

- What is induction furnace used for? Achieve Fast, Clean Metal Melting and Heat Treatment

- How does an induction furnace with a steel core generate heat for melting copper alloys? Efficiency and Principles

- What are the technical advantages of using an induction melting furnace? Precision for Nickel-Based Superalloys

- How do you melt metal in an induction furnace? A Guide to Fast, Clean & Efficient Melting

- What are the different types of induction heating? Choose the Right System for Your Melting & Heat Treating Needs

- Does copper heat up in induction? The Surprising Truth About Heating Non-Ferrous Metals

- What are the disadvantages of induction heater? Understanding the Cookware and Cost Trade-offs