At its core, Chemical Vapor Deposition (CVD) is a powerful manufacturing process used to create high-performance solid materials, typically as a thin film, from a gas. In this method, volatile precursor gases are introduced into a reaction chamber where they decompose and react on the surface of a heated object, known as a substrate. This chemical reaction results in the deposition of a new, solid layer of material directly onto the substrate's surface, building the film atom by atom.

The fundamental principle of CVD is not merely coating a surface, but rather constructing a new material layer through a controlled chemical reaction. It transforms gaseous ingredients into a solid film with precisely engineered properties, dictated by temperature, pressure, and gas composition.

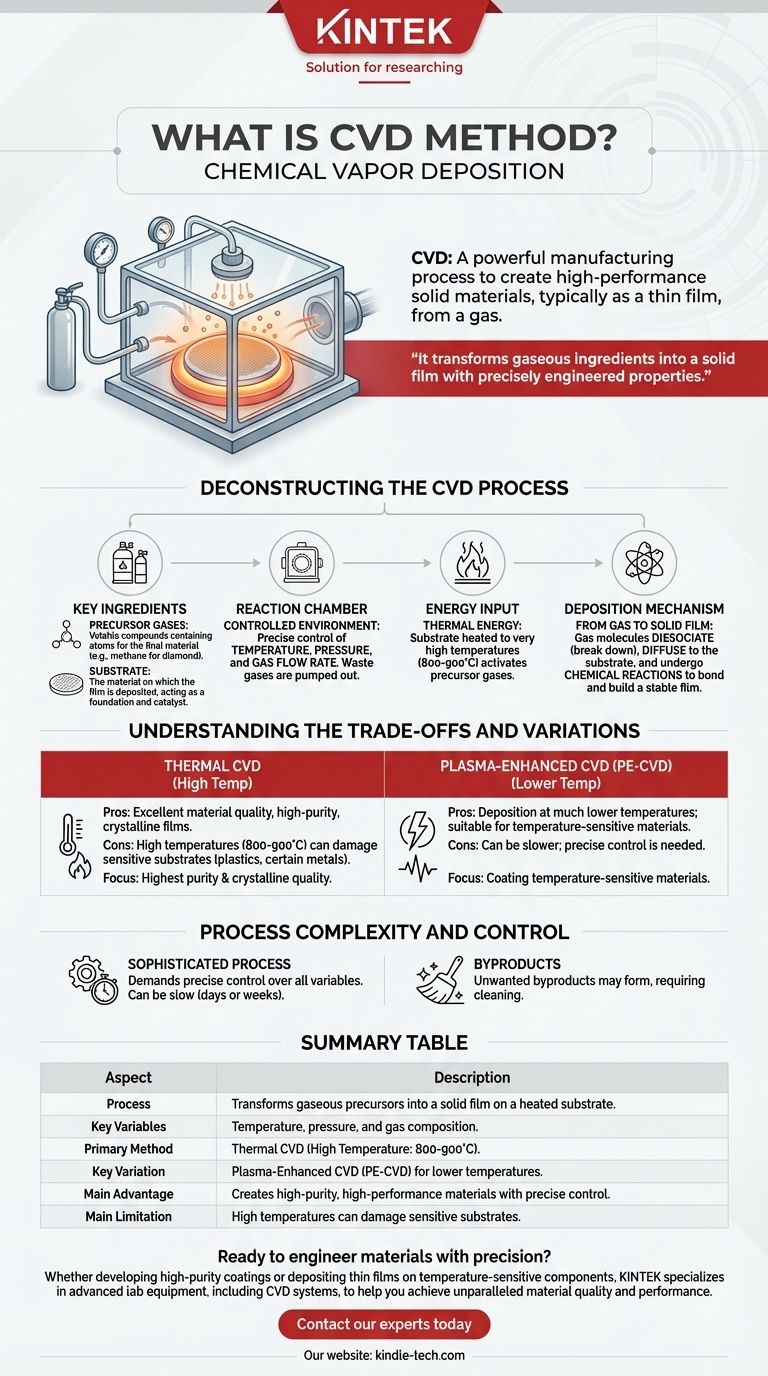

Deconstructing the CVD Process

To understand CVD, it's best to break it down into its essential components and stages. The entire process takes place within a highly controlled environment to ensure the purity and quality of the final material.

The Key Ingredients: Precursors and Substrate

The process begins with two primary components. The precursor gases are volatile compounds that contain the atoms of the desired final material. For example, to grow a diamond film, carbon-rich gases like methane are used.

The substrate is the material or object onto which the film is deposited. It acts as the physical foundation and often as a catalyst for the chemical reaction. Substrates can range from silicon wafers in electronics to diamond "seeds" for growing larger synthetic diamonds.

The Reaction Chamber: A Controlled Environment

All of this occurs within a sealed reaction chamber. This chamber allows for the precise control of critical environmental variables, including temperature, pressure, and the flow rate of the gases.

Waste gases and unreacted precursors are continuously pumped out of the chamber, preventing contamination and ensuring the chemical reaction proceeds as intended.

The Catalyst for Reaction: Energy Input

For the precursor gases to react and form a solid, they must be activated with energy. The method of energy input is a defining characteristic of the CVD type.

The most common method is thermal energy. The substrate is heated to a very high temperature, often between 800°C and 900°C. When the cooler precursor gases come into contact with the hot substrate, the heat provides the energy needed to trigger the chemical reaction on its surface.

The Deposition Mechanism: From Gas to Solid Film

Once energized, the gas molecules break down (dissociate) into reactive atoms and molecules. These species then move (diffuse) to the substrate's surface.

On the hot surface, these reactive species undergo a series of chemical reactions, bonding with the substrate and each other. This atomistic process builds up a stable, solid film that adheres strongly to the substrate.

Understanding the Trade-offs and Variations

While powerful, the CVD process is not a one-size-fits-all solution. The specific conditions required create important trade-offs that have led to the development of different CVD techniques.

High Temperature is a Double-Edged Sword

Traditional thermal CVD requires extremely high temperatures to achieve high-purity, crystalline films. This produces excellent material quality.

However, these high temperatures can damage or destroy substrates that are sensitive to heat, such as plastics, certain metals, or complex electronic components.

Plasma-Enhanced CVD (PE-CVD) for Lower Temperatures

To overcome the temperature limitation, a variation called Plasma-Enhanced CVD (PE-CVD) is used. In this method, an energy source like microwaves or radio frequency (RF) is used to ionize the gas into a plasma.

This plasma contains highly reactive ions and radicals that can form a film at much lower temperatures. This makes it possible to coat temperature-sensitive materials that would be incompatible with thermal CVD.

Process Complexity and Control

CVD is a sophisticated process that demands precise control over all variables. The process can be slow, sometimes taking days or weeks to grow a significant layer.

Furthermore, unwanted byproducts can sometimes form alongside the desired film (such as graphite forming during diamond growth), requiring technicians to periodically halt the process for cleaning.

Making the Right Choice for Your Goal

Selecting the correct CVD approach depends entirely on the requirements of your material and the limitations of your substrate.

- If your primary focus is the highest possible film purity and crystalline quality: High-temperature thermal CVD is often the preferred method, provided your substrate can withstand the heat.

- If your primary focus is coating a temperature-sensitive material: Plasma-Enhanced CVD (PE-CVD) is the essential choice, as it enables deposition at significantly lower temperatures.

By understanding these core principles, you can effectively leverage CVD to engineer materials with precisely controlled properties from the ground up.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Transforms gaseous precursors into a solid film on a heated substrate. |

| Key Variables | Temperature, pressure, and gas composition. |

| Primary Method | Thermal CVD (High Temperature: 800-900°C). |

| Key Variation | Plasma-Enhanced CVD (PE-CVD) for lower temperatures. |

| Main Advantage | Creates high-purity, high-performance materials with precise control. |

| Main Limitation | High temperatures can damage sensitive substrates. |

Ready to engineer materials with precision?

Whether you need to develop high-purity coatings for semiconductor wafers or deposit thin films on temperature-sensitive components, the right equipment is critical. KINTEK specializes in advanced lab equipment, including CVD systems, to help you achieve unparalleled material quality and performance.

Contact our experts today to discuss how our solutions can meet your specific research and production goals.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating