In essence, heat treatment is the controlled process of heating and cooling a material, most often a metal, to deliberately alter its internal microstructure. This is not about simply making a metal hot; it is a precise metallurgical discipline used to change a material's physical and sometimes chemical properties, such as hardness, strength, or ductility, to make it suitable for a specific engineering application.

Heat treatment is the critical link between a raw material and a high-performance component. By manipulating the material's internal grain structure through precise thermal cycles, you can unlock specific, desirable properties that are not inherent to the material in its base state.

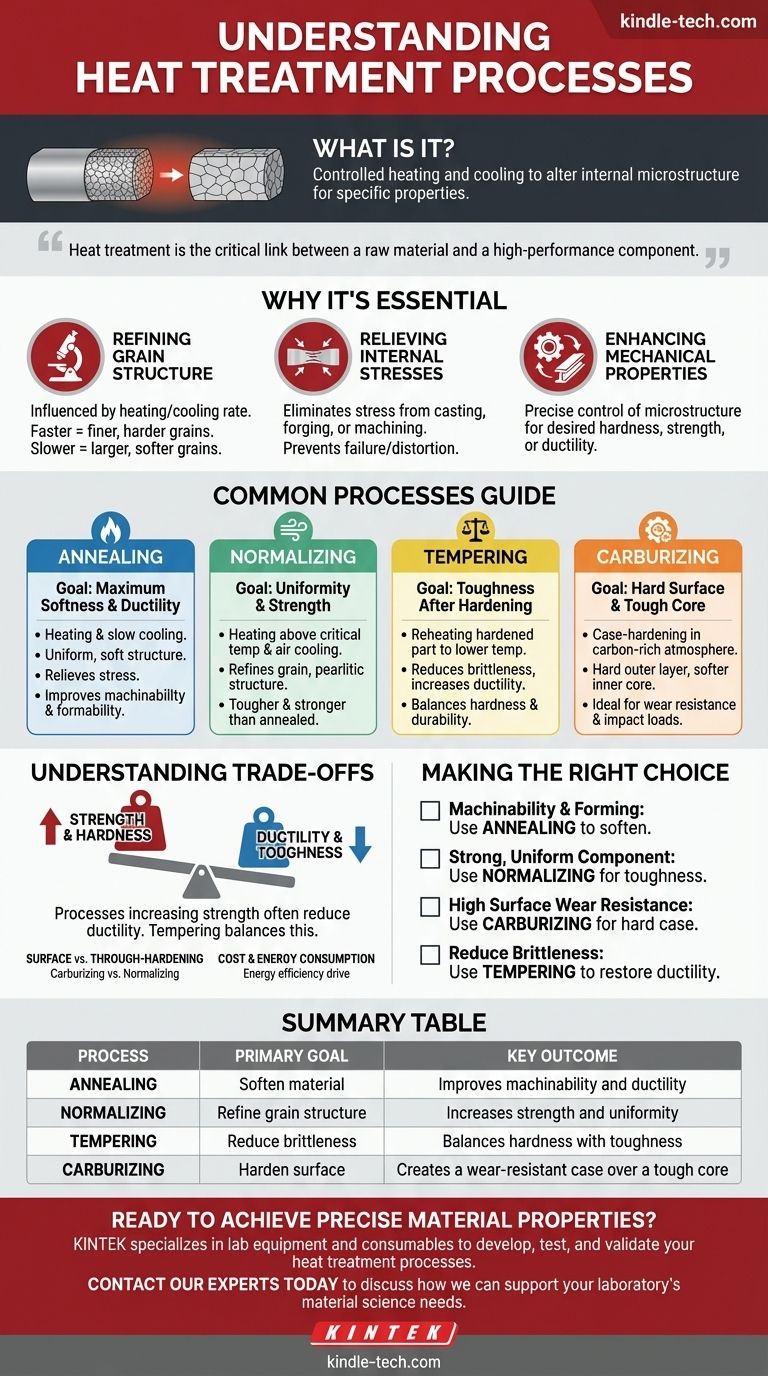

Why Heat Treatment is Essential

The core purpose of heat treatment is to modify a material's microstructure. Think of the metal's internal structure as a collection of microscopic crystals, or "grains." The size, shape, and arrangement of these grains dictate the material's overall mechanical behavior.

Refining Grain Structure

The rate of heating and cooling directly influences the final grain structure. Faster cooling rates, for example, tend to produce a finer, harder grain structure, while slower cooling allows for larger, softer grains to form.

Relieving Internal Stresses

Manufacturing processes like casting, forging, or machining can introduce significant stress within a material. Heat treatment can "relax" the atomic structure, relieving these internal stresses and preventing premature failure or distortion.

Enhancing Mechanical Properties

By controlling the microstructure, you can precisely dial in the desired properties. This allows you to take a standard piece of steel and transform it into either a flexible spring, a hard-wearing gear, or a tough structural beam.

A Guide to Common Heat Treatment Processes

While there are many specialized treatments, most fall into a few fundamental categories. The choice of process depends entirely on the material and the desired outcome.

Annealing: For Maximum Softness and Ductility

Annealing involves heating a metal and then cooling it very slowly. This process produces a uniform and soft microstructure, relieves internal stress, and reduces hardness.

The primary goal of annealing is to make the material easier to shape, machine, or form without the risk of it cracking.

Normalizing: For Uniformity and Strength

Applied to ferrous metals like steel, normalizing involves heating the material above its critical temperature and then cooling it in open air.

This process refines the grain size and creates a more uniform, pearlitic microstructure. A normalized component is tougher and slightly stronger than an annealed one and is often the final treatment for certain steel parts.

Tempering: For Toughness After Hardening

Tempering is a secondary process performed after a metal has already been hardened through a process like quenching. Hardened metals are often extremely brittle.

Tempering involves reheating the hardened part to a lower temperature to reduce that brittleness, significantly increasing its ductility and toughness. It's a balancing act to trade some hardness for much-needed durability.

Carburizing: For a Hard Surface and a Tough Core

Carburizing is a type of case-hardening, meaning it only modifies the surface of the component. The process involves heating steel in a carbon-rich atmosphere.

Carbon diffuses into the surface, which allows the outer layer to become exceptionally hard and wear-resistant while the inner core remains softer and tougher. This is ideal for parts like gears that must endure surface friction but also withstand impact loads.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it is a science of compromises. Understanding these trade-offs is critical to selecting the correct process.

Strength vs. Ductility

This is the most fundamental trade-off in metallurgy. Processes that increase a material's hardness and strength almost always reduce its ductility, making it more brittle. Tempering is the primary method used to find an acceptable balance between these two properties.

Surface vs. Through-Hardening

A process like carburizing creates a hard surface but leaves the core ductile. In contrast, normalizing or annealing affects the entire cross-section of the material. The choice depends on whether the primary threat is surface wear (requiring case-hardening) or bulk structural load (requiring through-treatment).

Cost and Energy Consumption

Heat treatment cycles can be long and energy-intensive, adding significant cost to a component. There is a continuous drive in the industry to develop more efficient processes, utilize waste heat, and replace long-cycle treatments with shorter, more economical alternatives without sacrificing quality.

Making the Right Choice for Your Application

Selecting the correct heat treatment requires a clear understanding of your component's end-use.

- If your primary focus is machinability and forming: Use annealing to soften the material, improve ductility, and relieve internal stress before further manufacturing steps.

- If your primary focus is creating a strong, uniform steel component: Use normalizing to refine the grain structure and increase toughness for reliable structural performance.

- If your primary focus is achieving high wear resistance on a surface: Use a case-hardening process like carburizing to create a hard outer layer while maintaining a tough core.

- If your primary focus is reducing the brittleness of a previously hardened part: Use tempering to restore essential ductility and toughness, preventing catastrophic failure.

By understanding these fundamental processes, you can specify the precise material properties required to ensure the performance and reliability of your components.

Summary Table:

| Process | Primary Goal | Key Outcome |

|---|---|---|

| Annealing | Soften material | Improves machinability and ductility |

| Normalizing | Refine grain structure | Increases strength and uniformity |

| Tempering | Reduce brittleness | Balances hardness with toughness |

| Carburizing | Harden surface | Creates a wear-resistant case over a tough core |

Ready to achieve the precise material properties your application demands? The right heat treatment is critical for performance and reliability. KINTEK specializes in the lab equipment and consumables needed to develop, test, and validate your heat treatment processes. Our expertise supports laboratories in optimizing thermal cycles for superior results. Contact our experts today to discuss how we can support your laboratory's material science needs.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- Why is a continuous flow of high-purity nitrogen required during the catalytic pyrolysis of plastics? Maximize Fuel Yield

- What is pressureless sintering? A Guide to High-Temperature Material Consolidation

- What is the process of batch pyrolysis? A Step-by-Step Guide to Converting Waste into Energy

- What is the process of rotavap? Master Efficient, Low-Temperature Solvent Evaporation

- What is the easiest to melt metal? Start with Tin and Pewter for Safe, Simple Casting

- Can aluminum be sputtered? Master the Process for High-Quality Thin Films

- What is the temperature dependence of graphite? Balancing Strength and Oxidation for High-Temp Use

- What are the hazards of heat treatment process? Avoid Oxidation, Embrittlement, and Costly Defects