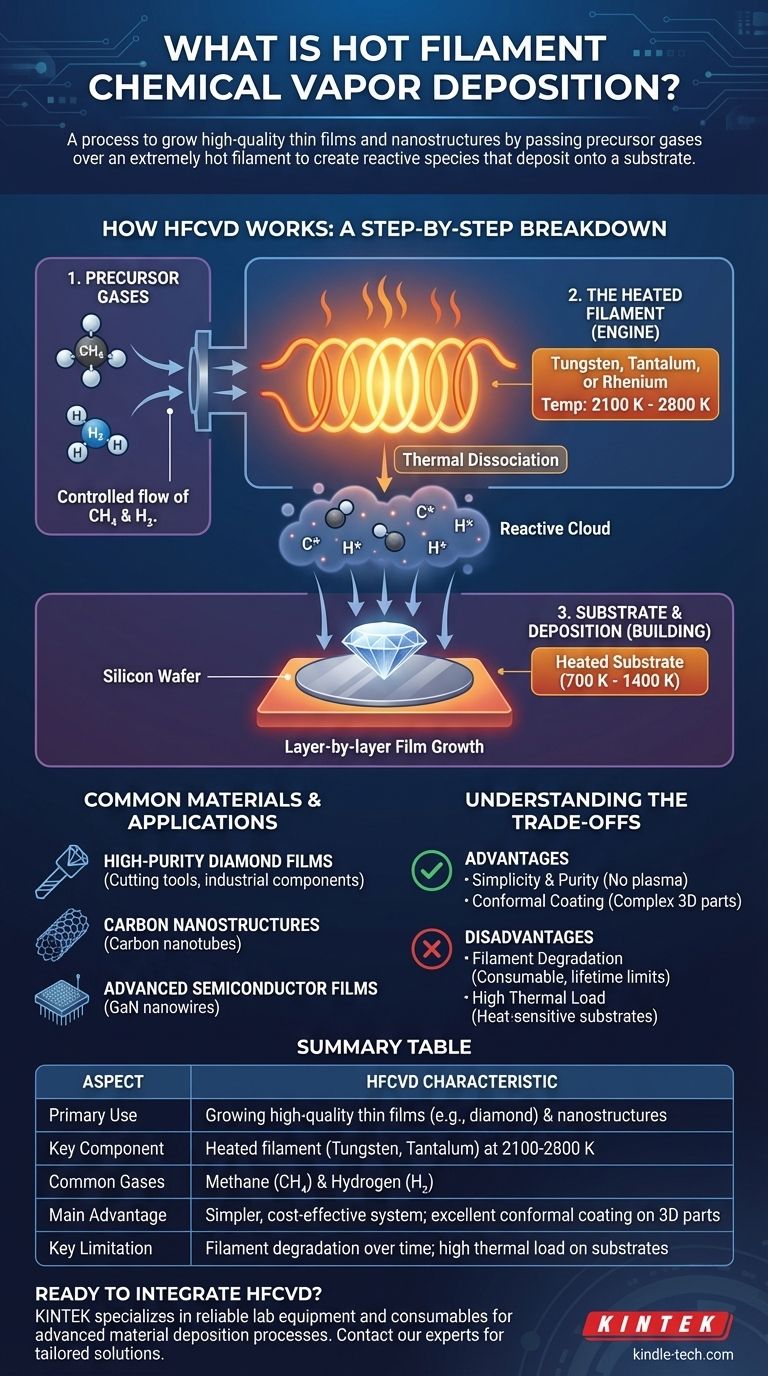

At its core, Hot Filament Chemical Vapor Deposition (HFCVD) is a process used to grow high-quality thin films and nanostructures onto a surface. It works by passing precursor gases over an extremely hot wire, or filament, which breaks the gases down into reactive chemical species that then deposit onto a nearby substrate to form the desired material layer.

HFCVD is a powerful and relatively simple method for creating high-purity films, most notably diamond, without the need for complex plasma systems. The central trade-off, however, is the process's complete reliance on a consumable filament that degrades over time, impacting process stability and maintenance cycles.

How HFCVD Works: A Step-by-Step Breakdown

HFCVD is a subtype of Chemical Vapor Deposition (CVD) that relies on thermal energy from a filament to drive the chemical reaction. The entire process takes place within a controlled vacuum chamber.

The Heated Filament: The Engine of the Process

The heart of the HFCVD system is a thin wire made from a refractory metal like tungsten (W), tantalum (Ta), or rhenium (Re). This filament is electrically heated to extreme temperatures, typically between 2100 K and 2800 K.

Its primary job is to provide the thermal energy needed to "crack" or dissociate the precursor gases into highly reactive chemical fragments.

The Precursor Gases: The Building Blocks

Gases are introduced into the chamber at a controlled rate. For diamond film deposition, the most common application, these are typically methane (CH4) as the carbon source and an excess of hydrogen (H2).

The hydrogen plays a dual role: it helps catalyze the reaction on the filament surface and also selectively etches away any non-diamond carbon that may form on the substrate, ensuring a high-purity film.

The Chemical Reaction: Activating the Species

As the gases flow over the incandescent filament, they are thermally dissociated. Methane breaks down into various carbon-hydrogen radicals, and the molecular hydrogen (H2) is split into highly reactive atomic hydrogen (H).

These activated species form a reactive chemical cloud in the vicinity of the filament and substrate.

The Substrate and Deposition: Building the Film

A substrate, such as silicon, is placed a short distance from the filament and is heated independently to a much lower temperature (typically 700 K to 1400 K).

The reactive species from the gas phase travel to the heated substrate surface, where they bond and arrange themselves into a crystalline structure. Over time, these atoms build up layer by layer, forming a dense, uniform, and high-quality film.

Common Materials and Applications

HFCVD is not a universal solution, but it excels in producing specific high-performance materials.

High-Purity Diamond Films

This is the most well-known application of HFCVD. The process can grow polycrystalline diamond films that are exceptionally hard and wear-resistant, making them ideal for coating cutting tools and industrial components.

Carbon Nanostructures

The process is also frequently used to synthesize other carbon allotropes, including one-dimensional structures like carbon nanotubes.

Advanced Semiconductor Films

HFCVD is a viable method for growing certain semiconductor materials, such as Gallium Nitride (GaN) nanowires, which are critical for advanced electronics and optoelectronics.

Understanding the Trade-offs

No deposition technique is perfect. Choosing HFCVD requires a clear understanding of its distinct advantages and inherent limitations.

Advantage: Simplicity and Purity

Compared to methods like Plasma-Enhanced CVD (PECVD), HFCVD systems are often simpler and less expensive to build and operate, as they do not require complex high-voltage power supplies or plasma-containment hardware. This absence of plasma can also lead to fewer impurities in the final film.

Advantage: Conformal Coating

Like all CVD processes, HFCVD is not a "line-of-sight" technique. The gaseous precursors can flow around and coat complex, non-uniform, and three-dimensional surfaces evenly. This is a significant advantage over Physical Vapor Deposition (PVD) methods, which struggle with shadowing.

Disadvantage: Filament Degradation

This is the single greatest drawback of HFCVD. The extremely hot filament reacts with the precursor gases, becoming brittle and prone to sagging or breaking over time. This filament lifetime limits the length of deposition runs and introduces process variability and downtime for maintenance.

Disadvantage: High Thermal Load

The incandescent filament radiates a tremendous amount of heat. This can make it difficult to deposit films on temperature-sensitive substrates that cannot withstand the high radiant thermal load without being damaged.

Making the Right Choice for Your Goal

Selecting the right deposition method depends entirely on your material, substrate, and operational priorities.

- If your primary focus is growing high-purity polycrystalline diamond or carbon films on a robust substrate: HFCVD offers a cost-effective and high-performance solution.

- If your primary focus is coating complex 3D parts uniformly: HFCVD is a strong candidate, providing superior conformal coverage compared to PVD.

- If your primary focus is process stability for long production runs or coating heat-sensitive materials: You should carefully evaluate alternatives like Plasma-Enhanced CVD to avoid the challenges of filament degradation and high radiant heat.

Ultimately, understanding these core principles empowers you to select the deposition technique that best aligns with your specific engineering goal.

Summary Table:

| Aspect | HFCVD Characteristic |

|---|---|

| Primary Use | Growing high-quality thin films (e.g., diamond) & nanostructures |

| Key Component | Heated filament (Tungsten, Tantalum) at 2100-2800 K |

| Common Gases | Methane (CH₄) & Hydrogen (H₂) |

| Main Advantage | Simpler, cost-effective system; excellent conformal coating on 3D parts |

| Key Limitation | Filament degradation over time; high thermal load on substrates |

Ready to integrate HFCVD into your lab workflow? KINTEK specializes in providing reliable lab equipment and consumables for advanced material deposition processes. Whether you are depositing diamond films for cutting tools or synthesizing carbon nanotubes for research, our expertise ensures you have the right tools for high-purity, uniform results. Contact our experts today to discuss how we can support your laboratory's specific needs with tailored solutions.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond Domes for Industrial and Scientific Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques