In aluminum metallurgy, quenching is the process of rapidly cooling an aluminum alloy after it has been heated to a specific temperature. This rapid cooling, typically done in water, oil, or forced air, does not primarily harden the aluminum. Instead, its critical function is to lock the alloy's internal structure into a specific, unstable state, which is the essential prerequisite for achieving high strength through a subsequent aging process.

Quenching aluminum is counter-intuitive when compared to steel. The process initially makes the metal softer and more workable by trapping alloying elements in solution. The desired hardness and strength are only developed later, during a process called "aging."

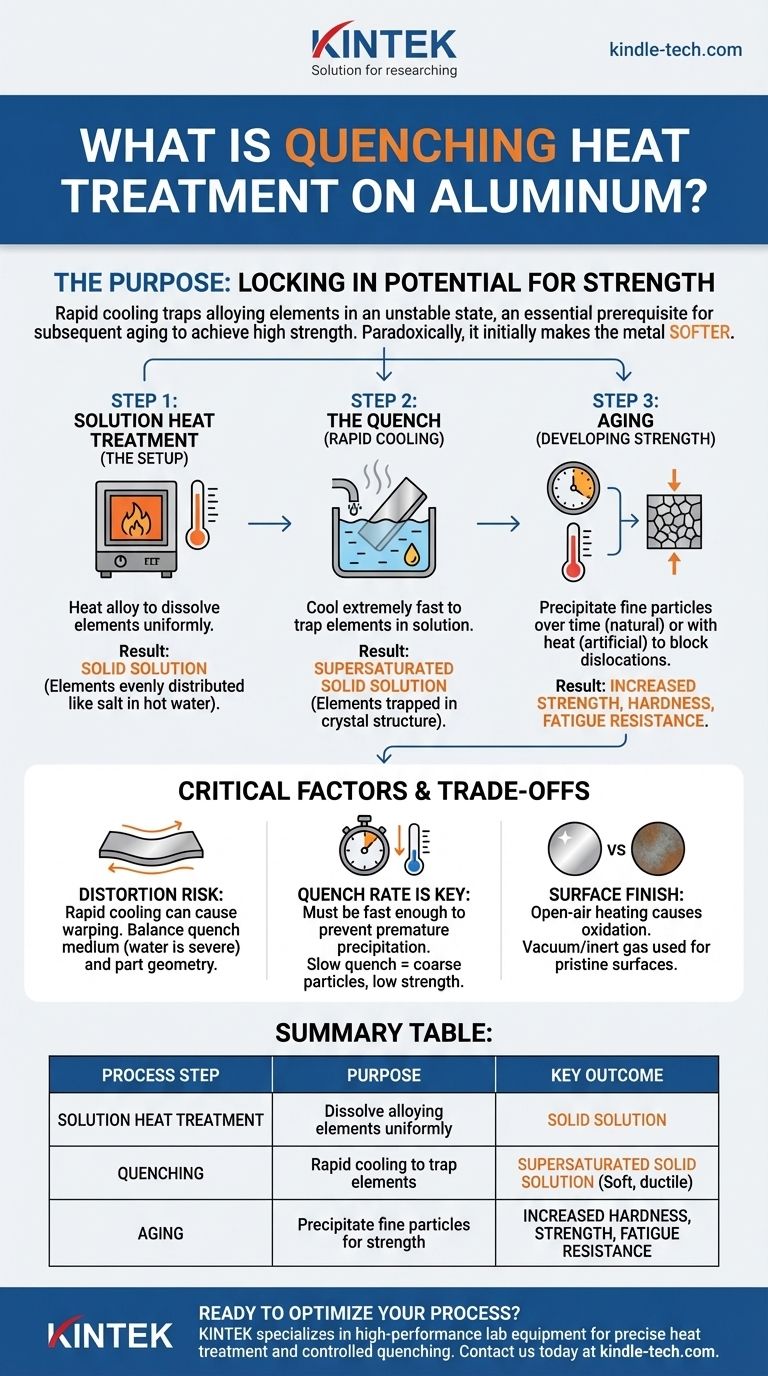

The Purpose of Quenching Aluminum

To understand quenching, you must first understand the process it is a part of: precipitation hardening. This is a three-step thermal treatment used on specific aluminum alloys.

Step 1: Solution Heat Treatment (The "Setup")

Before quenching, the aluminum alloy is heated to a high temperature, typically just below its melting point.

The goal of this step is to dissolve the primary alloying elements (like copper, silicon, or zinc) evenly into the aluminum matrix. Think of it like dissolving salt into hot water—the elements distribute themselves to form a uniform, single-phase structure called a solid solution.

Step 2: The Quench (Locking in Potential)

Once the elements are fully dissolved, the material is cooled with extreme rapidity. This is the quench.

This rapid cooling prevents the alloying elements from precipitating out of the solution as the metal cools. They are effectively trapped within the aluminum's crystal structure, creating a supersaturated solid solution.

Step 3: The Result of the Quench (A Softer State)

Immediately after quenching, the aluminum is in its softest, most ductile, and most workable condition.

This is because the trapped alloying elements have not yet formed the internal structures that impede deformation. This state is often referred to as the 'W' temper.

From Softness to Strength: The Role of Aging

The quenched state is only temporary. The real strength is developed in the final step, known as aging or precipitation treatment.

Natural and Artificial Aging

The trapped alloying elements will naturally begin to "precipitate" out of the supersaturated solution over time, even at room temperature. These precipitates are extremely fine, dispersed particles that act as blockages within the metal's crystal lattice.

This process is called natural aging and can take days or weeks. To accelerate and control this, the material can be reheated to a low temperature for a specific duration. This is called artificial aging or "tempering."

Final Mechanical Properties

These microscopic precipitates obstruct the movement of dislocations within the metal, which is how it resists deformation. The result is a dramatic increase in the aluminum's strength, hardness, and resistance to fatigue.

Understanding the Trade-offs and Critical Factors

While quenching is essential for high-strength aluminum, the process requires precise control to be successful.

The Risk of Distortion

The rapid temperature change during quenching induces significant internal stresses. Thin or complex-shaped parts are highly susceptible to warping or distortion. The choice of quenching medium (water is faster and more severe than oil or forced air) is a balance between cooling rate and distortion risk.

Quench Rate is Everything

The cooling must be fast enough to prevent uncontrolled precipitation of the alloying elements during the quench. If the quench is too slow, the elements will form large, coarse particles that contribute very little to final strength, effectively wasting the heat treatment.

Oxidation and Surface Finish

Heating aluminum in an open-air environment will cause an oxide layer to form on the surface. For many applications, this is not an issue. However, for components requiring a pristine surface or specific subsequent processing, the heat treatment may be performed in a vacuum or inert gas environment to prevent this oxidation.

Applying This to Your Project

The specific quenching and aging parameters you choose are dictated entirely by the final properties your component requires.

- If your primary focus is maximum strength and hardness: A very rapid quench (e.g., in cold water) is necessary to achieve the highest level of supersaturation, followed by a carefully controlled artificial aging cycle.

- If your primary focus is minimizing distortion: A less severe quench using a polymer solution, hot water, or forced air may be required, which often involves a slight trade-off in achieving the alloy's absolute peak strength.

- If your primary focus is machinability or formability: You will perform these operations on the aluminum after quenching but before aging, while the material is in its softest and most ductile state.

Understanding quenching is not just about cooling metal; it is about precisely controlling aluminum's internal structure to unlock its full performance potential.

Summary Table:

| Process Step | Purpose | Key Outcome |

|---|---|---|

| Solution Heat Treatment | Dissolve alloying elements uniformly | Creates a solid solution |

| Quenching | Rapid cooling to trap elements | Forms a supersaturated solid solution (soft, ductile state) |

| Aging | Precipitate fine particles for strength | Increases hardness, strength, and fatigue resistance |

Ready to optimize your aluminum heat treatment process? At KINTEK, we specialize in providing high-performance lab equipment and consumables tailored for metallurgical applications. Whether you need precise furnaces for solution heat treatment or controlled quenching systems, our solutions help you achieve superior material properties with minimal distortion. Contact us today to discuss how we can support your laboratory's specific needs in aluminum alloy development and processing!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals