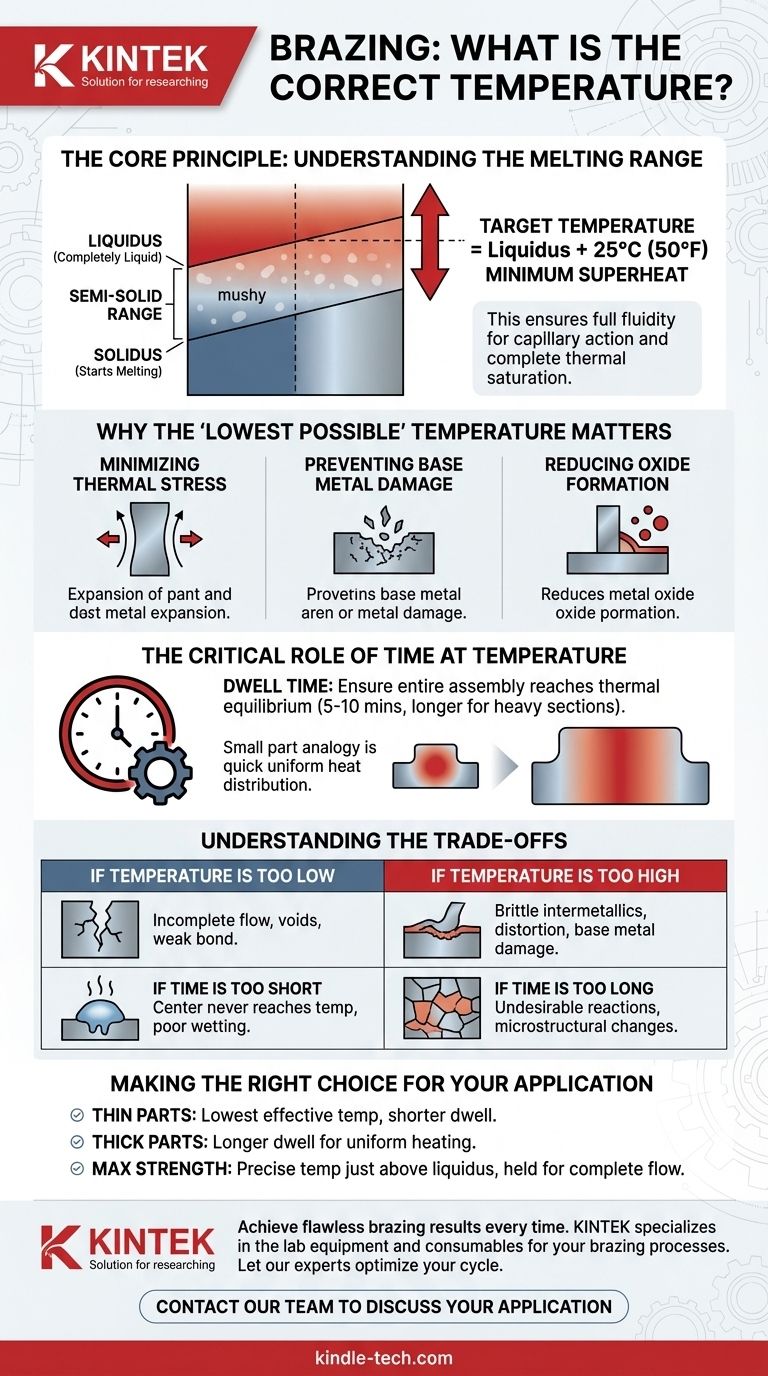

For a successful joint, the correct brazing temperature is not a single value but a specific target within a range. As a rule, you should aim for a temperature that is at least 25°C (50°F) above the full melting point (the liquidus) of your brazing filler metal. This ensures the alloy becomes fluid enough to flow completely into the joint via capillary action.

The goal is to find the lowest possible temperature that still guarantees full filler metal fluidity and complete thermal saturation of the assembly. This precise control minimizes thermal stress on the parts while ensuring a strong, reliable bond.

The Core Principle: Understanding the Melting Range

To control brazing temperature, you must first understand how brazing alloys melt. Unlike pure metals, alloys melt over a range of temperatures, not at a single point.

Defining Solidus and Liquidus

The solidus is the temperature at which the filler metal first begins to melt. Below this temperature, the alloy is completely solid.

The liquidus is the temperature at which the filler metal becomes completely liquid. The range between the solidus and liquidus is a "mushy" or semi-solid state.

The "Superheat" Rule of Thumb

Brazing must occur above the liquidus temperature. The standard practice is to add a buffer, often called "superheat," of at least 25°C (50°F) to the liquidus temperature.

This buffer ensures the filler metal is fully fluid and can overcome minor temperature drops as it flows into the comparatively cooler joint area.

Why the "Lowest Possible" Temperature Matters

While you must exceed the liquidus, using an excessively high temperature can be detrimental. Sticking to the lowest effective temperature within the recommended range provides several key advantages.

Minimizing Thermal Stress

Every material expands and contracts when heated and cooled. The higher the temperature, the greater this change, increasing the risk of distortion or stress fractures in the base materials.

Preventing Base Metal Damage

Excessively high temperatures can begin to damage the base metals being joined. This can include unwanted grain growth, which can weaken the material, or even erosion, where the filler metal begins to dissolve the base metal.

Reducing Oxide Formation

The rate of oxidation on metal surfaces increases exponentially with temperature. Operating at the lowest effective temperature minimizes the formation of oxides, which can inhibit filler metal flow and compromise joint integrity.

The Critical Role of Time at Temperature

Reaching the target temperature is only half the process. The duration you hold that temperature, known as dwell time, is equally critical.

Achieving Thermal Equilibrium

The goal is to ensure the entire assembly—including the thickest sections of every part—reaches a uniform brazing temperature. This is known as thermal equilibrium.

Only when the base metals at the joint are at the correct temperature will they properly "pull" the liquid filler metal into the gap via capillary action.

How Mass Affects Dwell Time

A small, thin part will heat up much faster than a large, heavy one. Dwell time must be long enough for the core of the thickest component in the assembly to reach the target temperature.

A typical dwell time is between 5 and 10 minutes, but this must be extended for very heavy or large furnace loads to ensure all parts are fully soaked.

Understanding the Trade-offs

Achieving a perfect braze requires balancing temperature and time. Deviating from the ideal process window introduces specific risks.

If Temperature is Too Low

Setting the temperature too close to the liquidus may not provide enough fluidity for the filler metal to flow completely through a long or very narrow joint, resulting in voids and a weak bond.

If Temperature is Too High

Excessive heat can cause the filler metal to react aggressively with the base metal, forming brittle intermetallic compounds that reduce the joint's ductility and strength. It also increases the risk of part distortion.

If Time is Too Short

Even if the furnace temperature is correct, insufficient dwell time means the center of the part may never reach the required temperature. The filler will melt but will "freeze" upon contacting the cooler base metal, preventing proper wetting and flow.

If Time is Too Long

Holding the parts at temperature for too long can lead to the same issues as excessive temperature. It can promote undesirable filler metal-base metal interactions and cause detrimental changes to the microstructure of the base materials.

Making the Right Choice for Your Application

Use these principles to fine-tune your brazing process based on the specific characteristics of your parts.

- If your primary focus is joining thin or delicate components: Use the lowest effective temperature and a carefully controlled, shorter dwell time to minimize the risk of distortion.

- If your primary focus is brazing thick, heavy sections: Plan for a longer dwell time to ensure the core of the material reaches the target temperature uniformly.

- If your primary focus is maximizing joint strength and consistency: Precisely control your temperature to just above the filler's liquidus and hold it only long enough for complete, verified flow.

Mastering the interplay between temperature and time is the key to creating repeatable, high-quality brazed joints.

Summary Table:

| Factor | Key Principle | Target/Goal |

|---|---|---|

| Temperature | Brazing must occur above the filler metal's liquidus point. | Liquidus + 25°C (50°F) minimum for full fluidity. |

| Dwell Time | The entire assembly must reach a uniform temperature (thermal equilibrium). | 5-10 minutes (longer for heavy sections). |

| Key Balance | Use the lowest effective temperature to minimize stress and damage. | Ensures strength while protecting base materials. |

Achieve flawless brazing results every time. The precise balance of temperature and time is critical for joint integrity. KINTEK specializes in the lab equipment and consumables that provide the control and consistency your brazing processes demand.

Let our experts help you optimize your brazing cycle for stronger, more reliable components.

Contact our team today to discuss your specific application and discover the right solutions for your laboratory needs.

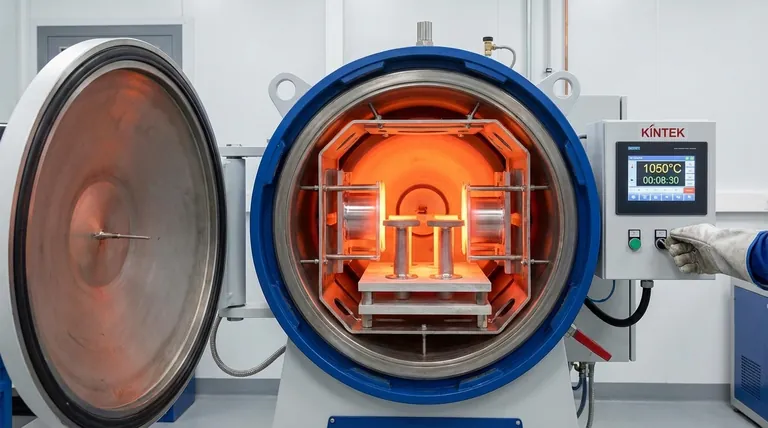

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency