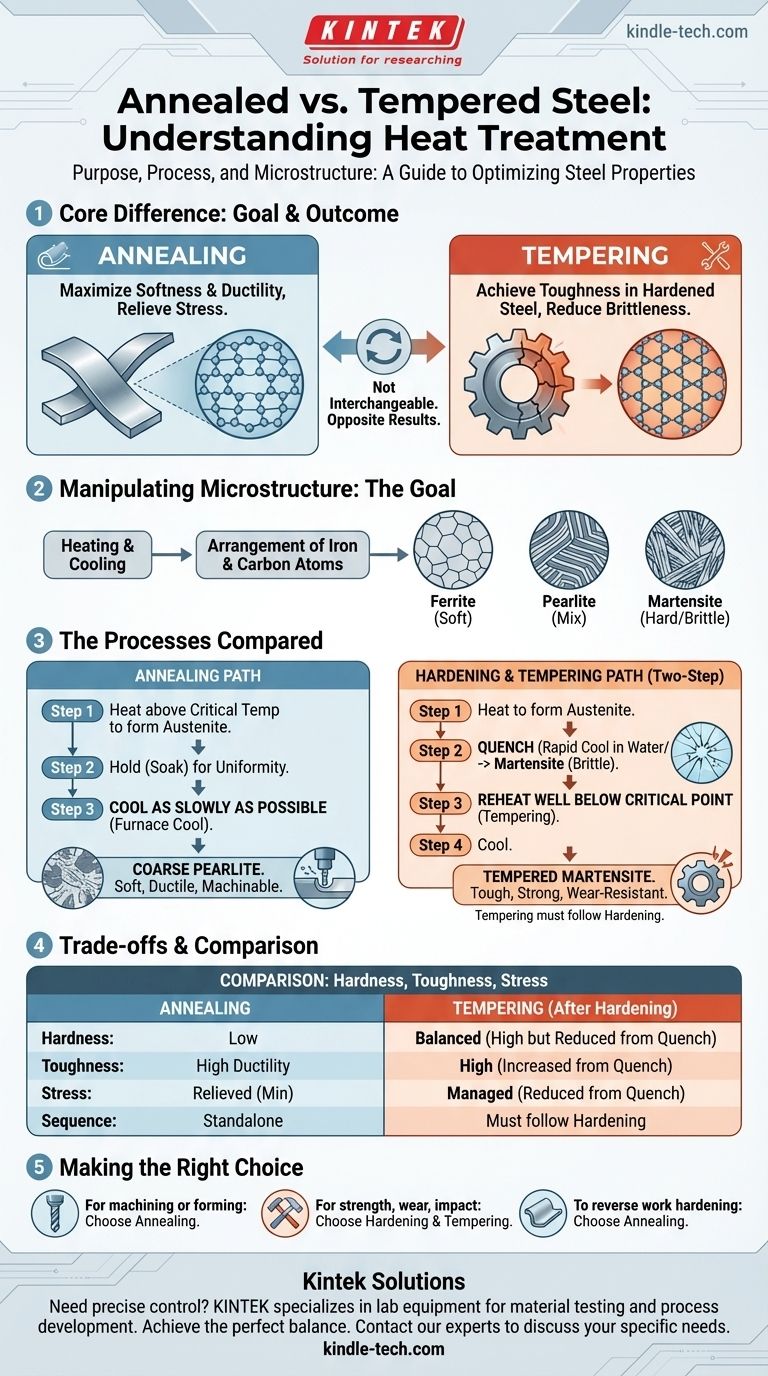

At its core, the difference is one of purpose and outcome. Annealing is a heat treatment process used to make steel as soft, ductile, and machinable as possible by relieving internal stresses. In contrast, tempering is a process performed after hardening steel to reduce its brittleness and increase its toughness, achieving a functional balance between hardness and durability. They are not interchangeable; in fact, they produce nearly opposite results.

The fundamental distinction lies in their goals: Annealing aims for maximum softness and stress relief, making steel easy to work with. Tempering aims to create toughness in an already hardened—and therefore brittle—piece of steel, making it durable for service.

The Goal of Heat Treatment: Manipulating Microstructure

To understand these processes, you must first understand that heat treatment is the art of controlling the internal crystal structure, or microstructure, of steel. Different structures yield vastly different mechanical properties.

Steel's Crystalline Building Blocks

Steel's properties are dictated by the arrangement of its iron and carbon atoms. Heating and cooling a part changes this arrangement. The key structures are ferrite (soft and ductile), pearlite (a mix of ferrite and hard iron carbide), and martensite (a highly strained, very hard, and brittle structure).

The Purpose of a Thermal Cycle

Every heat treatment process follows a thermal cycle: heating to a specific temperature, holding it for a period (soaking), and cooling at a controlled rate. The rate of cooling is the most critical factor in determining the final microstructure and, therefore, the steel's properties.

Annealing: The Path to Maximum Softness

Annealing is a process designed to put steel into its most stable and stress-free state. This is often done to prepare the material for subsequent manufacturing steps.

The Annealing Process Explained

The steel is heated above its critical transformation temperature, where its microstructure changes into a uniform state called austenite. After being held at this temperature to ensure uniformity, it is cooled as slowly as possible, often by leaving it inside the furnace to cool over many hours or even days.

The Resulting Microstructure: Coarse Pearlite

This extremely slow cooling allows the atomic structure to rearrange into its lowest-energy state, typically coarse pearlite. This structure has very low internal stress and hardness, resulting in a steel that is soft, highly ductile, and easy to machine or form.

When to Use Annealing

Annealing is used to relieve stresses from prior work (like cold rolling or forging), improve machinability before cutting operations, or soften a part to allow for extensive plastic deformation, such as deep drawing.

Hardening & Tempering: The Two-Step Path to Toughness

Tempering cannot be understood in isolation. It is the mandatory second step in a two-part process designed to create a finished part that is both hard and tough.

Step 1: Quenching for Maximum Hardness

First, the steel is heated above its critical temperature to form austenite, just like in annealing. However, it is then cooled as rapidly as possible by quenching it in a medium like water, oil, or air.

The Resulting Microstructure: Martensite

This rapid cooling traps the carbon atoms in a highly stressed, distorted crystal structure known as martensite. Martensite is extremely hard and wear-resistant but also incredibly brittle, like glass. A part that is only hardened is often too fragile for any practical application.

Step 2: Tempering to Reduce Brittleness

To correct this brittleness, the hardened part is reheated to a much lower temperature, well below its critical point. It is held at this temperature for a set time and then cooled. The precise temperature is crucial, as it dictates the final balance of properties.

The Resulting Microstructure: Tempered Martensite

This reheating allows some carbon atoms to precipitate out, relieving the extreme internal stresses of the martensite. The result is tempered martensite, a refined microstructure that sacrifices a small amount of hardness for a significant gain in toughness—the ability to absorb impact and resist fracture.

Understanding the Trade-offs: A Direct Comparison

Choosing between these processes requires a clear understanding of their opposing effects.

Hardness vs. Toughness

Annealing maximizes softness and ductility at the expense of hardness and strength. It creates a material that is easy to shape.

Tempering achieves toughness in a previously hardened material. The higher the tempering temperature, the more hardness is sacrificed for an increase in toughness.

Internal Stress

Annealing is a stress-relieving process. Its primary goal is to remove as much internal stress as possible.

Hardening (quenching) induces massive internal stress. Tempering's function is to manage and reduce that stress to a functional level, preventing catastrophic failure.

Process Sequence

Annealing is a standalone process. A part can be annealed and be considered finished for its purpose (e.g., ready for machining).

Tempering is never a standalone process. It is fundamentally linked to and must follow a hardening (quenching) cycle. You cannot temper a soft, unhardened piece of steel.

Making the Right Choice for Your Application

Your choice of heat treatment must be directly aligned with the final performance requirements of the component.

- If your primary focus is preparing steel for machining or extensive cold forming: Annealing is the correct process to maximize softness and relieve internal stress.

- If your primary focus is creating a final part that is strong, wear-resistant, and can withstand impact: Hardening followed by tempering is the required two-step sequence to achieve the necessary toughness.

- If your primary focus is reversing the effects of work hardening from a process like bending or stamping: Annealing is what you need to restore ductility for further work or to prevent cracking.

Ultimately, understanding the distinct purpose of each heat treatment empowers you to precisely dictate the final performance of a steel component.

Summary Table:

| Process | Goal | Key Action | Resulting Property |

|---|---|---|---|

| Annealing | Maximize softness & ductility | Heat & cool very slowly | Soft, machinable, stress-free steel |

| Hardening & Tempering | Achieve toughness & durability | Harden (quench) then temper (reheat) | Tough, strong, wear-resistant steel |

Need precise control over your steel's properties? The right heat treatment is critical for performance. KINTEK specializes in the lab equipment and consumables needed for material testing and process development. Whether you're researching new alloys or ensuring quality control, our solutions help you achieve the perfect balance of hardness, strength, and toughness. Contact our experts today to discuss how we can support your laboratory's specific needs.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the temperature accuracy of a muffle furnace? Achieve Precise and Uniform Heating

- What is the use of muffle furnace in pharmaceuticals? Essential for Purity & Quality Control

- What is the use of muffle furnace in chemistry? Achieve Contaminant-Free Heating for Accurate Analysis

- What are the uses of muffle furnaces? Achieve Precise, Contamination-Free High-Temperature Processing

- What is the use of muffle furnace in food laboratory? Essential for Accurate Nutritional Analysis & Quality Control