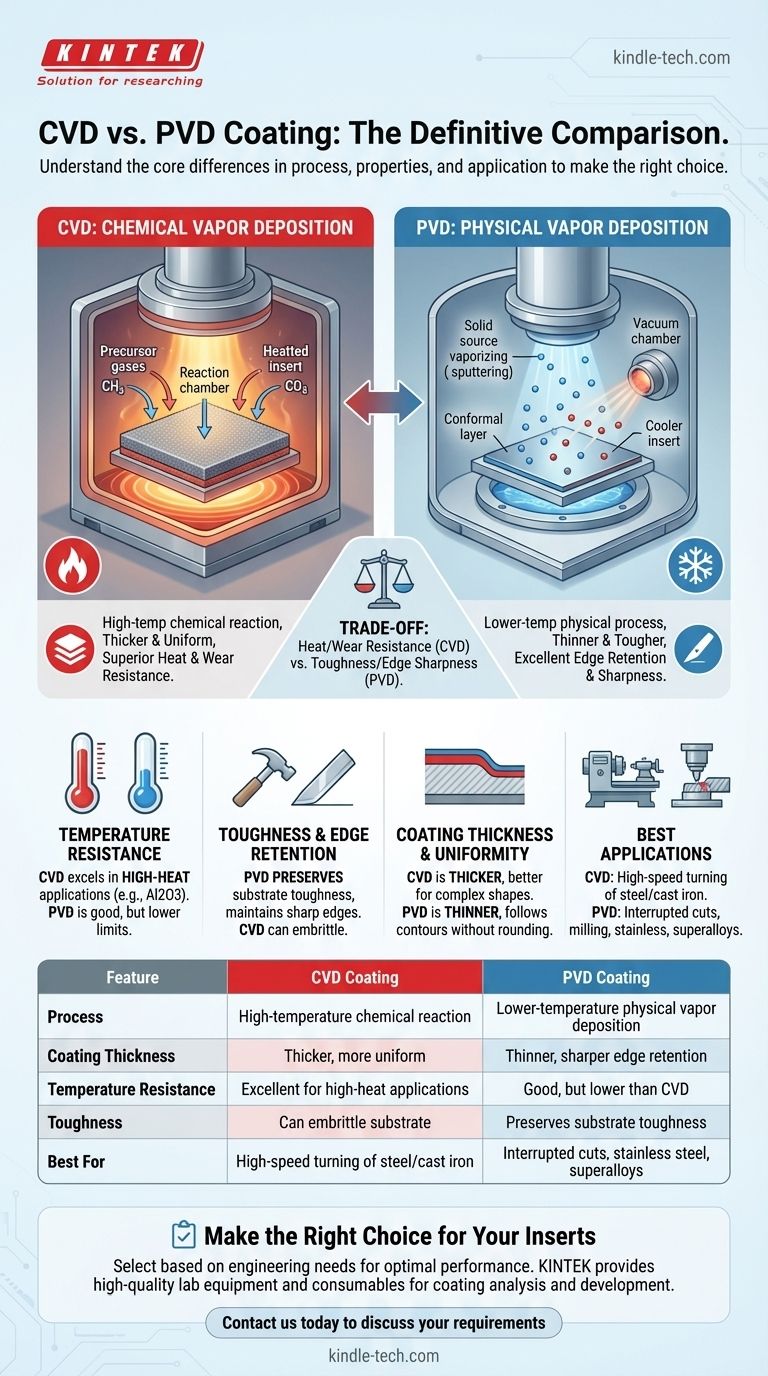

The fundamental difference between CVD and PVD coatings lies in their application process and the resulting properties. Chemical Vapor Deposition (CVD) uses a high-temperature chemical reaction to form a thick, wear-resistant layer. In contrast, Physical Vapor Deposition (PVD) uses a lower-temperature physical process to create a thinner, tougher, and smoother coating.

Choosing between them is not a matter of which is superior overall, but which possesses the right characteristics for a specific machining application. The choice hinges on a trade-off between the heat and wear resistance of CVD and the toughness and edge sharpness of PVD.

The Core Mechanisms: Chemical vs. Physical

The application method is the source of all the key differences between these two coating technologies. It dictates the temperature, coating structure, and how the coating interacts with the tool substrate.

Chemical Vapor Deposition (CVD): A High-Temperature Reaction

CVD involves introducing volatile precursor gases into a chamber where they react on the surface of the heated cutting insert. This chemical reaction builds the coating layer by layer.

This process requires very high temperatures, which is a critical factor. The resulting coatings, particularly those using Aluminum Oxide (Al2O3), are extremely hard and chemically stable, making them ideal for high-heat environments.

Physical Vapor Deposition (PVD): A Line-of-Sight Process

PVD is a purely physical process conducted in a vacuum. A solid source material is vaporized (through methods like evaporation or sputtering) and the atoms travel in a straight line to deposit onto the insert's surface.

Because it does not rely on a chemical reaction, PVD can be performed at much lower temperatures. This preserves the underlying toughness of the carbide substrate and allows for a wider range of coating materials.

Key Performance Characteristics Compared

The differences in the application process lead directly to distinct advantages and disadvantages in a machining environment.

Temperature Resistance and Hardness

CVD coatings excel in high-temperature applications. The use of materials like Al2O3 gives them superior thermal stability and abrasive wear resistance, making them the standard choice for high-speed machining of cast iron and steel.

PVD coatings, while continually improving, have traditionally been less effective at the highest temperatures where CVD coatings thrive.

Toughness and Edge Retention

PVD is the clear winner for applications requiring a sharp, tough cutting edge. The lower processing temperature does not make the carbide substrate brittle, preserving its inherent toughness.

This makes PVD ideal for milling, tapping, or any operation with interrupted cuts, where the tool edge is subjected to repeated impacts.

Coating Thickness and Uniformity

CVD creates thicker, more uniform coatings. The gaseous nature of the process allows it to coat complex geometries, including deep holes and internal walls, with excellent consistency.

PVD coatings are thinner and can have less "throwing power" into deep features, but they provide excellent coverage on sharp cutting edges without rounding them.

Adhesion and Substrate Integrity

PVD's lower temperature is a significant advantage for maintaining the integrity of the cutting tool's substrate. It avoids the potential for embrittlement that can occur during the high-heat CVD process.

This makes PVD a safer choice for tools where toughness and resistance to chipping are the primary concerns.

Understanding the Trade-offs

Neither technology is a universal solution. Recognizing their limitations is key to making an informed decision.

The Cost Factor

CVD is often a cheaper process, especially for large batches. It allows for high-density loading in the coating reactor, reducing the cost per tool.

PVD is generally more expensive due to the complex vacuum technology and the more intricate process of loading and fixing tools within the chamber.

The Substrate Limitation

The high heat of the CVD process limits its use to substrates that can withstand it without losing their mechanical properties. This is a primary reason PVD is used for heat-sensitive tool materials.

Application Creep

While these guidelines are strong, PVD technology is advancing rapidly. New PVD coating compositions are constantly being developed that push into performance areas once dominated by CVD, blurring the lines for some applications.

Making the Right Choice for Your Inserts

Your selection should be driven entirely by the demands of your specific machining goal.

- If your primary focus is high-speed turning or milling of steel and cast iron: Choose CVD for its unmatched thermal stability and abrasive wear resistance at high temperatures.

- If your primary focus is machining stainless steels, superalloys, or non-ferrous materials: Choose PVD for its sharp, tough edge and smoother surface finish, which reduces built-up edge.

- If your primary focus is interrupted cuts (e.g., milling, shaping): Choose PVD to leverage the superior toughness of the substrate and avoid chipping.

- If your primary focus is cost-effectiveness for general-purpose wear applications: CVD often provides a more economical solution with excellent overall protection.

By understanding these core principles, you can select a coating based on engineering needs, ensuring optimal performance and tool life for your application.

Summary Table:

| Feature | CVD Coating | PVD Coating |

|---|---|---|

| Process | High-temperature chemical reaction | Lower-temperature physical vapor deposition |

| Coating Thickness | Thicker, more uniform | Thinner, sharper edge retention |

| Temperature Resistance | Excellent for high-heat applications | Good, but lower than CVD |

| Toughness | Can embrittle substrate | Preserves substrate toughness |

| Best For | High-speed turning of steel/cast iron | Interrupted cuts, stainless steel, superalloys |

Optimize your machining process with the right coating technology. The choice between CVD and PVD coatings is critical for tool performance, lifespan, and cost-efficiency. KINTEK specializes in providing high-quality lab equipment and consumables for coating analysis and development, serving the precise needs of laboratories and manufacturing facilities. Let our experts help you select the ideal coating solution for your specific application. Contact us today to discuss your requirements and discover how KINTEK can enhance your operational outcomes.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- Is diamond coating worth it? Maximize Component Life and Performance

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance