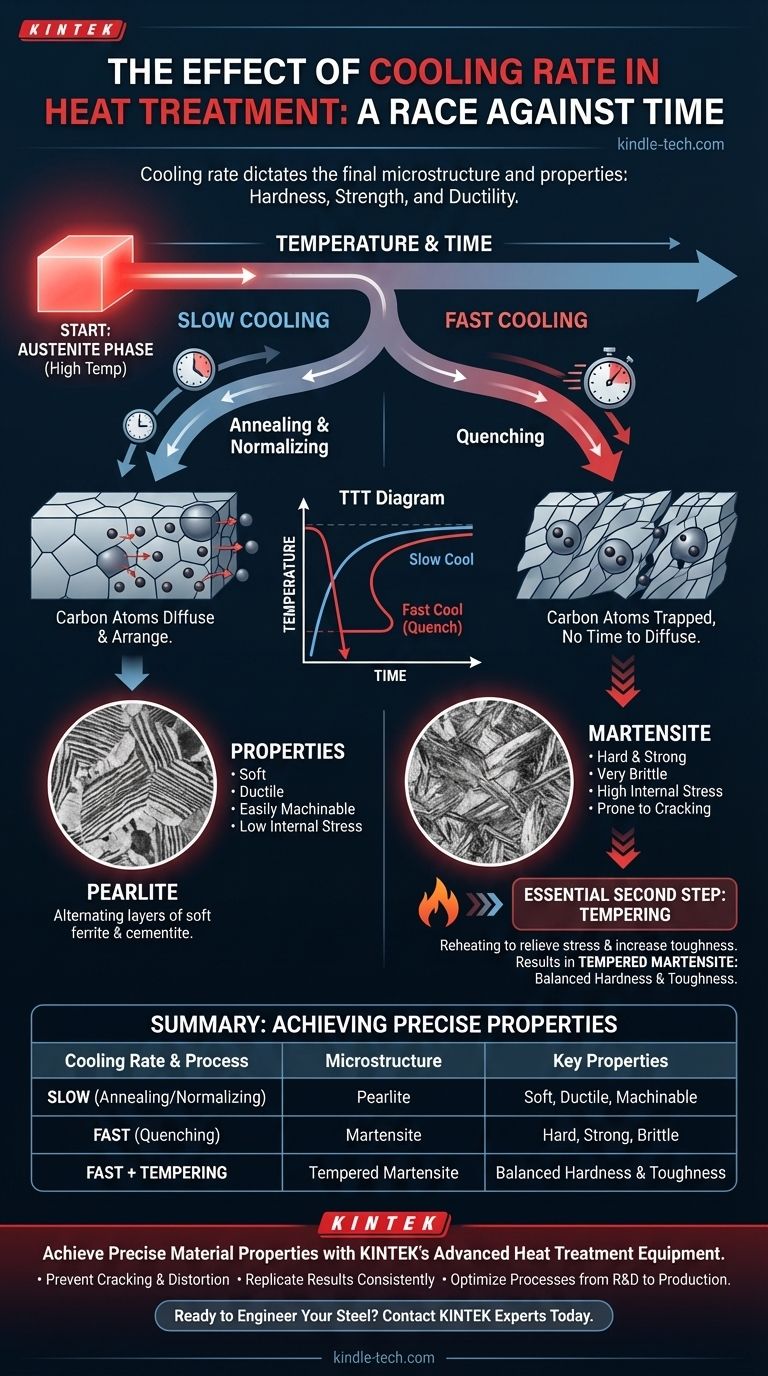

In heat treatment, the cooling rate is the single most important variable that determines a metal's final mechanical properties. It directly controls which microscopic structure, or "phase," forms as the metal cools from its high-temperature austenitic state, dictating the final balance between hardness, strength, and ductility. A faster cooling rate produces a harder, more brittle material, while a slower rate results in a softer, more ductile one.

The core principle is a race against time. Slower cooling allows atoms the time to diffuse and arrange themselves into soft, stable structures. Rapid cooling denies them this time, trapping the atomic structure in a highly stressed, unstable, and extremely hard state.

The Foundation: From Austenite to Final Microstructure

To understand cooling rates, you must first understand the transformation they control. The entire process begins when steel is heated to a critical temperature.

Starting Point: The Austenite Phase

At high temperatures (typically above 727°C or 1340°F), the atoms in steel arrange into a uniform, stable structure called austenite. In this state, carbon is fully dissolved within the iron lattice, creating a consistent solid solution. This austenitic state is the universal starting point for almost all heat treatments.

The Role of Carbon Diffusion

As the steel cools, the austenite becomes unstable and wants to transform into a different, more stable structure. This transformation hinges on the ability of carbon atoms to move, or diffuse, through the iron crystal lattice to form new phases. The speed of cooling directly dictates how much time the carbon atoms have to move.

The Roadmap: Time-Temperature-Transformation (TTT) Diagrams

Metallurgists use Time-Temperature-Transformation (TTT) diagrams as a roadmap for heat treatment. These charts plot temperature versus time and show the curves that represent the start and finish of a phase transformation. By tracing a cooling path on this diagram, you can predict the final microstructure.

How Cooling Rate Dictates the Outcome

The path your cooling curve takes through the TTT diagram determines the final product. A steep curve (fast cooling) will yield a completely different result than a shallow curve (slow cooling).

Slow Cooling (Annealing and Normalizing)

When steel is cooled slowly, such as by leaving it in a turned-off furnace (annealing) or in still air (normalizing), the cooling curve passes through the upper regions of the TTT diagram.

This gives carbon atoms ample time to diffuse out of the austenite. They form alternating layers of soft iron (ferrite) and iron carbide (cementite), creating a microstructure known as pearlite. The result is a soft, ductile, and easily machinable material with low internal stress.

Rapid Cooling (Quenching)

When steel is cooled extremely rapidly by plunging it into a medium like water, oil, or brine (quenching), the cooling is so fast that it completely "misses the nose" of the pearlite transformation curve on the TTT diagram.

Because the carbon atoms have no time to diffuse, they become trapped within the iron lattice. This forces the structure to shear into a new, highly strained, and distorted phase called martensite. This is known as a diffusionless transformation.

The Properties of Martensite

Martensite is exceptionally hard and strong but also extremely brittle, like glass. The trapped carbon atoms create immense internal stress within the crystal lattice, making the material prone to fracture under impact. For this reason, a part is almost never used in its as-quenched state.

Understanding the Trade-offs and Pitfalls

Controlling the cooling rate is a balancing act. Achieving one property often means sacrificing another, and pushing the limits can lead to failure.

The Hardness vs. Toughness Dilemma

The fundamental trade-off in heat treatment is hardness versus toughness.

- Fast Cooling: Creates martensite, which is very hard and wear-resistant but brittle (low toughness).

- Slow Cooling: Creates pearlite, which is very tough and ductile but soft (low hardness).

This is why quenching is almost always followed by a secondary heat treatment called tempering, which sacrifices some hardness to regain essential toughness.

The Danger of Cracking and Distortion

The immense internal stresses generated during a rapid quench can cause the part to warp, distort, or even crack. Thicker sections cool slower than thinner sections, creating a stress differential that can pull the part out of shape or, in worst-case scenarios, cause catastrophic failure.

The Role of Quenching Medium

The choice of quenchant is critical for controlling the cooling rate. Each medium has a different cooling severity:

- Brine (salt water): Fastest, most severe quench. Highest risk of cracking.

- Water: Very fast, but less severe than brine.

- Oil: Slower than water, providing a less drastic quench for more sensitive steels.

- Air: Slowest quench, used for highly alloyed "air-hardening" steels.

The Essential Second Step: Tempering

Because as-quenched martensite is too brittle for nearly all practical applications, it must be tempered.

Why Tempering is Necessary

Tempering is a stress-relieving process that reduces the brittleness of a quenched part and significantly increases its toughness. This makes the material durable and useful.

The Tempering Process

Tempering involves reheating the hardened part to a specific temperature below the austenite region (e.g., 200-650°C or 400-1200°F) and holding it for a set time. This process gives the trapped carbon atoms just enough energy to diffuse slightly, relieving the internal stresses within the martensite and forming fine carbide precipitates. The higher the tempering temperature, the more hardness is traded for greater toughness.

Choosing the Right Cooling Rate for Your Goal

Your choice of cooling rate should be driven entirely by the desired end-properties of the component.

- If your primary focus is maximum softness and machinability: Use a very slow furnace cool (annealing) to produce a coarse pearlite structure.

- If your primary focus is maximum hardness and wear resistance: Use a very rapid quench to achieve 100% martensite, followed by a low-temperature temper to relieve stress without significantly reducing hardness.

- If your primary focus is a balance of high strength and good toughness: Use a rapid quench to form martensite, followed by a mid-to-high temperature temper to achieve the exact point on the hardness-toughness spectrum your application requires.

- If your primary focus is refining grain structure and improving toughness over as-rolled steel: Use a moderate air cool (normalizing) to produce a fine pearlite structure.

By deliberately controlling the rate of cooling, you are engineering the microstructure of the steel to deliver the precise performance required for its task.

Summary Table:

| Cooling Rate | Process | Microstructure | Key Properties |

|---|---|---|---|

| Slow | Annealing/Normalizing | Pearlite | Soft, Ductile, Machinable |

| Fast (Quench) | Quenching | Martensite | Hard, Strong, Brittle |

| Fast + Tempering | Quench & Temper | Tempered Martensite | Balanced Hardness & Toughness |

Achieve precise material properties with KINTEK's advanced heat treatment equipment.

Whether you're annealing for softness, quenching for maximum hardness, or tempering for the perfect balance of strength and toughness, the right equipment is critical. KINTEK specializes in lab furnaces, ovens, and quenching systems that deliver the exact cooling rates your processes demand.

Our solutions help you:

- Prevent Cracking & Distortion: With precise temperature and cooling control.

- Replicate Results: Ensure consistency batch after batch.

- Optimize Processes: From R&D to production, achieve your desired material properties.

Ready to engineer your steel's microstructure for superior performance? Contact our experts today to find the perfect heat treatment solution for your laboratory needs.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is a high-temp muffle furnace essential for ZnO-WO3 & ZnO-BiOI? Optimize Heterojunction Catalyst Performance

- Why is precise temperature control in a calcination furnace essential for nano-silica? Optimize Your Rice Husk Processing

- What role does a high-temperature muffle furnace play in thermal stability testing? Study Nb-22.5Cr-5Si Alloy Resilience

- What is the inside material of the muffle furnace? Discover the Refractory Core for High-Temp Precision

- What specific process conditions must a muffle furnace provide for Fe-Cu composite treatment? Unlock Peak Performance

- How hot is a muffle furnace in Celsius? A Guide to Temperature Ranges from 800°C to 1800°C

- What function does a high-temperature muffle furnace serve in Ti3AlC2 MAX phase synthesis? Master Molten Salt Diffusion

- What are the advantages of using a forced convection oven with ventilation when processing organic xerogels?