The final stage of sintering is the culmination of the process, where a powder compact, already densified to over 90% of its theoretical density, undergoes final pore elimination. During this phase, the interconnected pore network from the intermediate stage has collapsed, leaving behind isolated, spherical pores. The primary goal is to shrink and remove these last voids to achieve a nearly fully dense, solid part, but this must be balanced against the risk of rapid grain growth.

The central challenge of final stage sintering is a race against time: you must eliminate the remaining isolated porosity before rapid grain growth traps those pores within the grains, permanently limiting the component's maximum achievable density and performance.

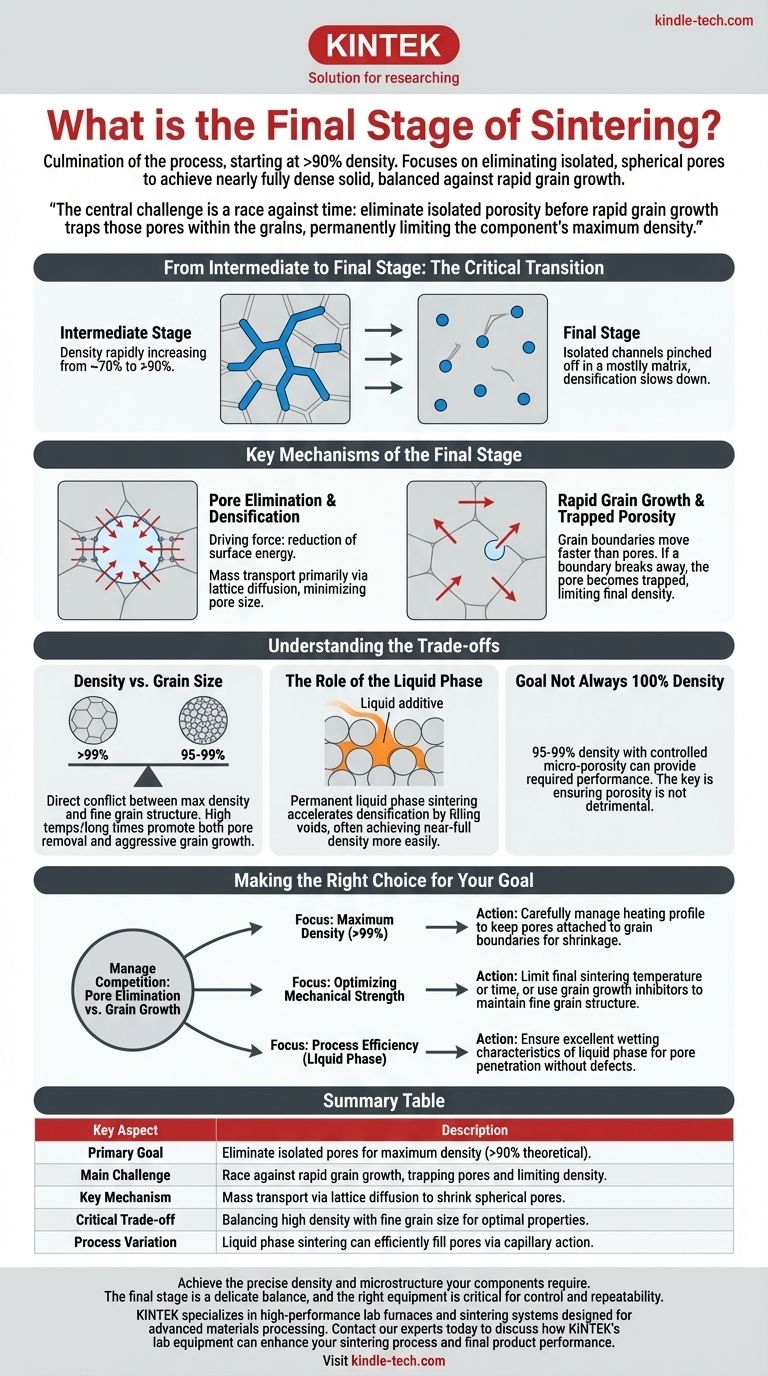

From Intermediate to Final Stage: The Critical Transition

The sintering process is a continuum, but the shift from the intermediate to the final stage is marked by a significant change in the material's internal structure, or microstructure.

The Intermediate Stage Structure

In the middle of the process, particles have already fused, and significant densification has occurred. The defining characteristic is a network of interconnected, cylindrical pores running along the grain boundaries. Density typically increases rapidly from around 70% to over 90% during this phase.

The Onset of the Final Stage

The final stage begins when these interconnected pore channels pinch off and become isolated, individual voids. At this point, the material is a solid matrix containing discrete, often spherical pores. The rate of densification slows considerably.

Key Mechanisms of the Final Stage

With the material now mostly solid, the final transformations are driven by subtle atomic movements aimed at minimizing the last remaining surface energy stored in the pores.

Pore Elimination and Densification

The driving force for final densification is the reduction of surface energy. Atoms diffuse from the high-energy, curved surfaces of the grain boundaries to the surfaces of the pores, causing the pores to shrink and eventually vanish. This mass transport primarily occurs through lattice diffusion, a process where atoms move through the crystal structure of the grains themselves.

The Challenge of Grain Growth

Simultaneously, grains tend to grow larger to reduce the total area of grain boundaries, which also lowers the system's energy. This rapid grain growth is a defining and often problematic feature of the final stage.

Grain boundaries can move faster than the pores they contain. If a grain boundary breaks away from a pore, that pore becomes trapped inside a single grain.

Trapped Porosity: The Limiting Factor

Once a pore is trapped within a grain, it is extremely difficult to remove. The diffusion paths required to eliminate it are much longer and less efficient. This entrapped porosity effectively puts a ceiling on the final density of the part, which is why controlling grain growth is paramount.

Understanding the Trade-offs

The final stage is not just a passive process; it involves critical trade-offs that determine the final properties of the component.

Density vs. Grain Size

There is a direct conflict between achieving maximum density and maintaining a fine grain structure. The conditions that promote final pore removal (high temperatures, long hold times) are the exact same conditions that promote aggressive grain growth. Since smaller grains often lead to better mechanical properties like strength and toughness, a compromise must be made.

The Role of the Liquid Phase

In some processes, like permanent liquid phase sintering, a liquid additive is present. In the final stage, this liquid flows into the last remaining pores under capillary pressure. This can effectively fill the voids and accelerate densification, often achieving near-full density more easily than in solid-state sintering.

The Goal is Not Always 100% Density

While often the goal, achieving 100% theoretical density is not always necessary or desirable. For many functional components, a final density of 95-99% with some fine, residual micro-porosity provides the required performance and dimensional precision. The key is ensuring this porosity is controlled and not detrimental.

Making the Right Choice for Your Goal

Controlling the final stage is crucial for engineering a component with the desired microstructure and performance characteristics.

- If your primary focus is achieving maximum density (>99%): You must carefully manage the heating profile to keep pores attached to grain boundaries, allowing them to shrink before the boundaries can break away.

- If your primary focus is optimizing mechanical strength: You may need to limit the final sintering temperature or time, or use grain growth inhibitors, to maintain a fine grain structure, even if it means accepting slightly lower density.

- If your primary focus is process efficiency using a liquid phase: Ensure the liquid phase has excellent wetting characteristics to penetrate the final pores without causing part distortion or forming undesirable chemical phases.

Mastering the final stage of sintering is about managing the competition between pore elimination and grain growth to achieve the precise microstructure your component requires.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Eliminate isolated pores to achieve maximum density (>90% theoretical). |

| Main Challenge | Race against rapid grain growth, which can trap pores and limit final density. |

| Key Mechanism | Mass transport via lattice diffusion to shrink and remove spherical pores. |

| Critical Trade-off | Balancing high density with fine grain size for optimal mechanical properties. |

| Process Variation | Liquid phase sintering can fill pores more efficiently using capillary action. |

Achieve the precise density and microstructure your components require. The final stage of sintering is a delicate balance, and the right equipment is critical for control and repeatability. KINTEK specializes in high-performance lab furnaces and sintering systems designed for advanced materials processing. Whether your goal is maximum density, optimized strength, or process efficiency, our solutions provide the precise temperature profiles and stable environments needed to master the final stage. Contact our experts today to discuss how KINTEK's lab equipment can enhance your sintering process and final product performance.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a high-temperature muffle furnace play in the pyrolysis stage of preparing silicon carbide? Achieve 1500°C Precision

- What is the role of a high-temperature box furnace in 9Cr-1Mo steel normalizing? Achieve Precise Microstructure Control

- What is sintering in a muffle furnace? Master Precision Thermal Processing for Advanced Materials

- What role does a program-controlled box resistance furnace play in the microstructural control of Al0.6CoCrFeNi/5052Al?

- What role does the air atmosphere in a high-temperature calcination furnace play? Optimize MgCuCeOx Adsorbent Activation

- What is the function of high-temperature digestion furnaces and lithium borate fluxes? Expert REE Sample Preparation

- What is the precaution for muffle furnace? Essential Safety Protocols for Lab Excellence

- What are 2 uses of oven in the laboratory? Essential for Sterilization and Drying