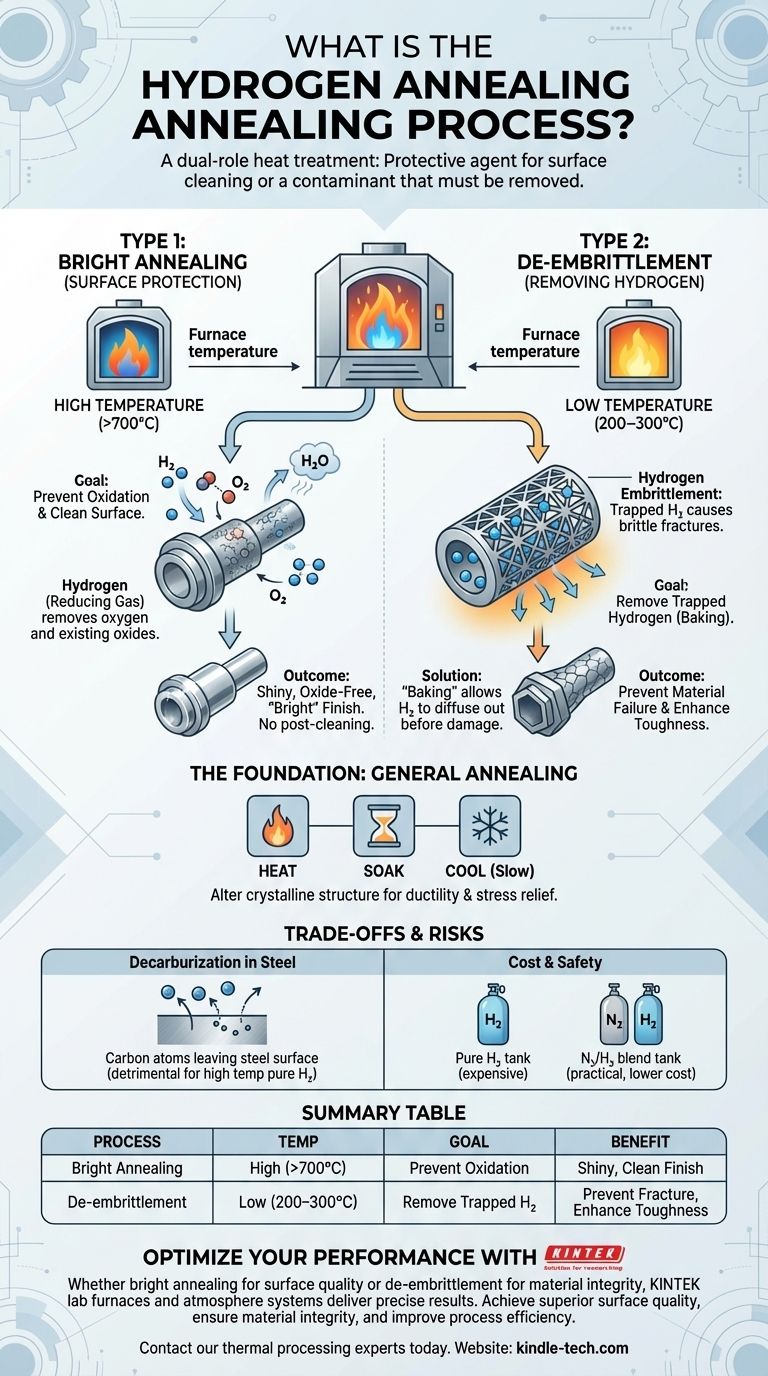

In metallurgy, hydrogen annealing is a heat treatment process that uses a controlled hydrogen atmosphere to alter a material's properties. It is most commonly used as "bright annealing" to create a clean, oxide-free surface, but the term can also refer to a low-temperature "baking" process designed to remove trapped hydrogen and prevent material failure. Understanding which process is needed is critical for achieving the desired outcome.

Hydrogen plays a dual role in heat treatment. It can be a powerful protective agent that cleans metal surfaces during high-temperature annealing, or it can be a dangerous contaminant that must be removed through low-temperature annealing to prevent catastrophic failure.

The Foundation: What Is General Annealing?

Annealing is a foundational heat treatment process used to make metals softer and more workable. It is not one specific process, but a category of treatments with a shared goal.

The Three Core Steps

The process involves three main stages: heating the material to a specific temperature, holding it at that temperature for a set duration (a step known as "soaking"), and then cooling it at a controlled, often slow, rate.

The Primary Outcome: Ductility and Stress Relief

This controlled thermal cycle alters the material's internal crystalline structure. It relieves internal stresses, reduces hardness, and increases ductility, making the metal easier to bend, shape, or machine without cracking.

Type 1: Using Hydrogen for Surface Protection (Bright Annealing)

When engineers refer to "hydrogen annealing," they are typically talking about bright annealing. In this process, hydrogen is an active and beneficial part of the furnace atmosphere.

How Hydrogen Prevents Oxidation

Hydrogen is a powerful reducing gas. At high temperatures, it actively reacts with and removes oxygen from the environment and from the surface of the metal itself, preventing the formation of oxides (scale or tarnish) that would otherwise occur.

The Benefit: A Clean and 'Bright' Finish

Because oxidation is prevented, the metal emerges from the furnace with a clean, shiny, and 'bright' surface. This eliminates the need for post-treatment cleaning or pickling, saving time and resources.

Why It's Called 'Surface Cleaning'

The reducing nature of hydrogen goes beyond just preventing oxidation; it can also "clean" parts that are already slightly oxidized. The hydrogen chemically reduces existing oxides on the metal, turning them into water vapor that is then carried away.

Type 2: Removing Hydrogen to Prevent Failure (De-embrittlement)

Confusingly, a very different process is also associated with hydrogen. This low-temperature treatment aims to remove hydrogen that has become trapped inside the metal.

The Danger: What is Hydrogen Embrittlement?

During processes like welding, electroplating, or galvanizing, individual hydrogen atoms can diffuse into the metal's crystal structure. These trapped atoms can cause a phenomenon called hydrogen embrittlement, which severely reduces the material's ductility and toughness, leading to unexpected and brittle fractures under stress.

The Solution: 'Baking' the Material

This removal process, often called de-embrittlement or baking, involves heating the material to a relatively low temperature (typically 200–300°C) for several hours. This gives the trapped hydrogen atoms enough energy to diffuse out of the material before they can cause damage.

Understanding the Trade-offs and Risks

While powerful, using hydrogen in annealing is not without significant considerations. The choice to use it involves balancing its benefits against clear operational risks and costs.

The Risk of Decarburization in Steel

For certain types of steel, a pure hydrogen atmosphere can be detrimental. At high temperatures, the hydrogen can react with the carbon within the steel, a process called decarburization. This removal of carbon weakens the steel's surface, which can be a critical failure point.

The High Cost of Pure Hydrogen

A 100% hydrogen atmosphere is effective but also the most expensive option for furnace atmospheres due to the cost of producing, storing, and safely handling the gas.

A Practical Alternative: Nitrogen-Hydrogen Blends

To balance cost and performance, many operations use a non-flammable mixture of nitrogen and hydrogen (typically less than 5% H₂). This blend still provides a reducing atmosphere capable of preventing oxidation for many applications but is significantly less expensive and safer to handle than pure hydrogen.

How to Apply This to Your Project

The correct "hydrogen annealing" process depends entirely on whether hydrogen is the solution to your problem or the cause of it.

- If your primary focus is achieving a pristine, oxide-free surface: Use bright annealing in a hydrogen or, more commonly, a cost-effective nitrogen-hydrogen atmosphere.

- If your primary focus is preventing material failure in steel after welding or coating: Use low-temperature de-embrittlement (baking) to remove trapped hydrogen and avoid embrittlement.

- If your primary focus is general stress relief and softening without strict surface requirements: A standard annealing process in a less reactive atmosphere (like nitrogen or argon) is often the most practical and economical choice.

Ultimately, mastering hydrogen in metallurgy means knowing when to use it as a protective tool and when to treat it as a contaminant that must be eliminated.

Summary Table:

| Process Type | Temperature Range | Primary Goal | Key Benefit |

|---|---|---|---|

| Bright Annealing | High (e.g., >700°C) | Prevent oxidation, clean surface | Shiny, oxide-free finish, no post-cleaning needed |

| De-embrittlement (Baking) | Low (200–300°C) | Remove trapped hydrogen | Prevent brittle fracture, enhance material toughness |

Optimize Your Metal's Performance with KINTEK's Expertise

Whether you need a pristine, oxide-free surface through bright annealing or want to eliminate the risk of hydrogen embrittlement in your critical components, KINTEK has the solution. Our advanced lab furnaces and atmosphere control systems are designed to deliver precise, reliable results for a wide range of metals and alloys.

We help you:

- Achieve superior surface quality without costly post-treatment cleaning.

- Ensure material integrity by safely removing harmful hydrogen.

- Improve process efficiency with reliable, high-performance equipment.

Don't let oxidation or embrittlement compromise your products. Contact our thermal processing experts today to discuss your specific application and discover how KINTEK's lab equipment can enhance your results.

Visual Guide

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is atmosphere controlled furnace? Prevent Oxidation and Enable Advanced Material Processing

- What are the safety precautions for argon welding? Essential Guide to Protecting Against UV, Fumes, Shock, and Asphyxiation

- How does a lab atmosphere furnace help synthesize PdCuAu alloys? Optimize Your Material Research Results

- Why are controlled atmosphere furnaces required for NCD coating modification? Unlock Superior Biocompatibility.

- How does argon prevent oxidation? The Science Behind Inert Gas Shielding

- What gases are used in brazing welding? Key Insights for Strong, Clean Joints

- How do vacuum or atmosphere furnaces enable near-net-shape forming during the reaction sintering of Silicon Carbide?

- What is the atmosphere of a heat treatment furnace? Mastering Surface Chemistry for Superior Materials