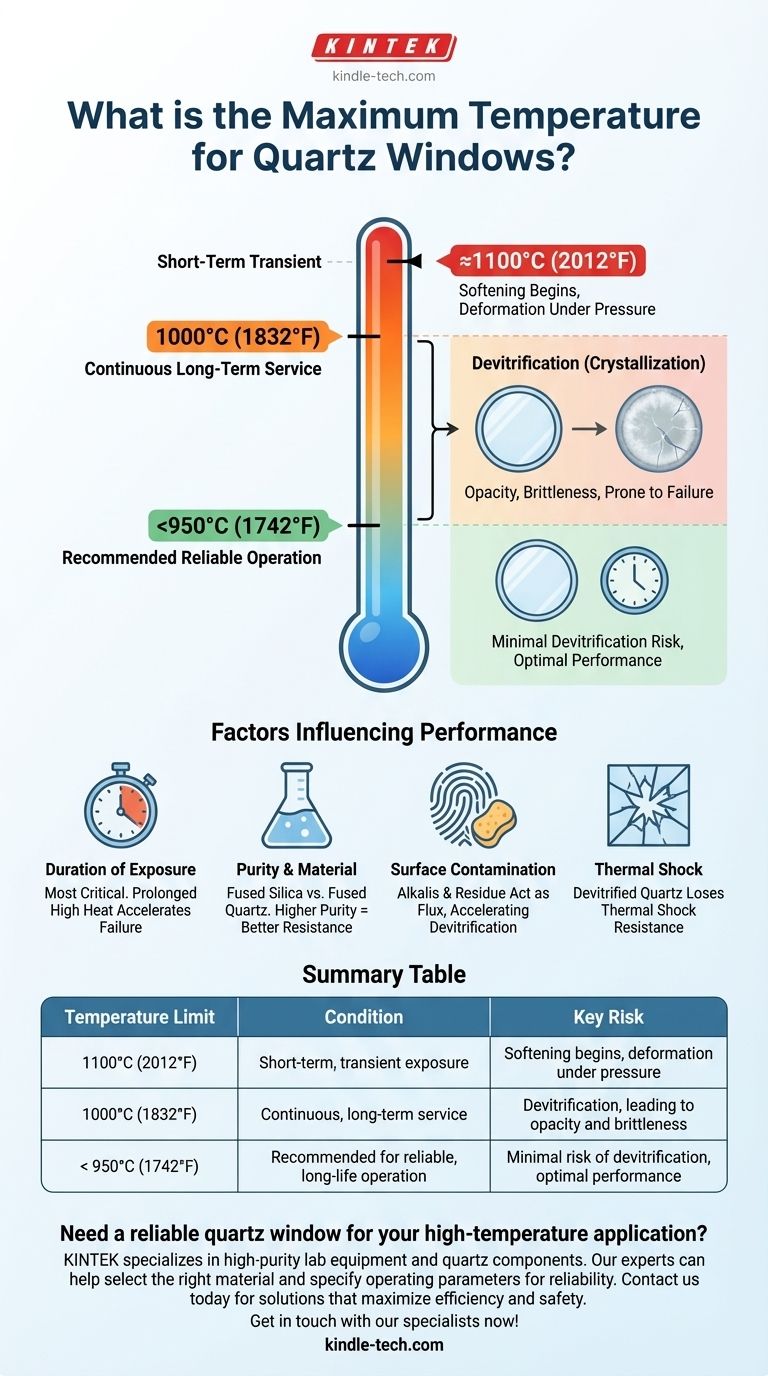

In general, the maximum short-term operating temperature for a transparent quartz window is approximately 1100°C (2012°F). At this temperature, the material begins to soften. For continuous or long-term use, however, the practical service temperature is significantly lower to avoid permanent structural damage.

While quartz can survive brief temperature spikes near its 1100°C softening point, the critical factor for reliability is its long-term service temperature, which should not exceed 1000°C. Sustained operation above this threshold causes devitrification—a crystalline transformation that makes the quartz opaque, brittle, and prone to failure.

The Science Behind Quartz's Temperature Limit

To properly specify a quartz window, you must understand not just its absolute limit, but how it behaves under thermal stress over time. The "maximum temperature" is not a single number but a function of time and material stability.

The Softening Point vs. The Melting Point

Unlike metals, quartz glass does not have a sharp, defined melting point. As an amorphous solid, it gradually loses viscosity and begins to soften as temperature rises.

The commonly cited figure of 1100°C represents this softening point (also known as the annealing point). At this temperature, internal stresses can be relieved, but the material also begins to deform under its own weight or any external pressure.

The True Limiting Factor: Devitrification

The most significant constraint for long-term, high-temperature applications is a process called devitrification.

At sustained temperatures, typically starting around 1000°C, the amorphous (non-crystalline) structure of fused quartz begins to revert to a stable crystalline state, most often cristobalite. This process is irreversible.

The Impact of Devitrification

Devitrification is the primary mode of failure for quartz in high-temperature environments. The newly formed crystals are a different material phase with different properties.

This transformation results in:

- Loss of Transparency: The window becomes cloudy or opaque, compromising its optical function.

- Reduced Mechanical Strength: The material becomes brittle and weak, dramatically increasing the risk of cracking or catastrophic failure.

- Thermal Expansion Mismatch: The crystalline areas expand and contract differently than the surrounding quartz glass, creating internal stress that can cause fractures during heating or cooling cycles.

Factors That Influence Performance

The safe operating temperature is not fixed. It depends on several variables related to the material's purity, the application's demands, and the operating environment.

Duration of Exposure

This is the most critical factor. A quartz window may tolerate a brief thermal excursion to 1100°C, but it will quickly devitrify if held at that temperature. For continuous service, staying below 1000°C is essential for a reasonable service life.

Purity and Material Type

"Quartz" often refers to fused quartz or fused silica. Fused silica is a synthetic, extremely pure form of Silicon Dioxide (SiO₂), while fused quartz is made from melting natural quartz crystals. The higher purity of fused silica gives it a slightly better resistance to devitrification.

Surface Contamination

Contaminants, particularly alkalis (like salts or even the residue from fingerprints), can act as a flux. They dramatically accelerate the devitrification process, lowering the temperature at which it begins. Keeping the window surface perfectly clean is critical for high-temperature work.

Thermal Shock

Quartz has an extremely low coefficient of thermal expansion, giving it world-class resistance to thermal shock. However, if the material has already started to devitrify, its ability to withstand rapid temperature changes is severely compromised.

Making the Right Choice for Your Application

Choosing the correct operating parameters is about balancing performance requirements with the material's physical limitations to ensure reliability and longevity.

- If your primary focus is short, intermittent heating cycles: You can operate with peaks approaching 1000°C, but it is critical to keep the duration at that peak to a minimum.

- If your primary focus is continuous, long-term operation (e.g., a furnace viewport): Design your system to keep the quartz window at or below 950°C to ensure a long and reliable service life.

- If your primary focus is absolute reliability in a critical environment: Maintain a conservative safety margin by operating below 900°C and implement a schedule for inspecting the window for any signs of cloudiness (devitrification).

- If your application consistently requires temperatures above 1000°C: You must consider a more exotic and expensive material, such as a sapphire window, which remains stable at much higher temperatures.

By understanding these thermal properties, you can confidently specify and operate quartz components for maximum performance and lifespan.

Summary Table:

| Temperature Limit | Condition | Key Risk |

|---|---|---|

| 1100°C (2012°F) | Short-term, transient exposure | Softening begins, deformation under pressure |

| 1000°C (1832°F) | Continuous, long-term service | Devitrification (crystallization) leading to opacity and brittleness |

| < 950°C (1742°F) | Recommended for reliable, long-life operation | Minimal risk of devitrification, optimal performance |

Need a reliable quartz window for your high-temperature application?

KINTEK specializes in high-purity lab equipment and consumables, including quartz components designed for thermal stability and longevity. Our experts can help you select the right material and specify the correct operating parameters to prevent devitrification and ensure your system's reliability.

Contact us today to discuss your specific requirements and let our team provide a solution that maximizes your lab's efficiency and safety. Get in touch with our specialists now!

Visual Guide

Related Products

- Vacuum Cold Mounting Machine for Sample Preparation

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Molybdenum Vacuum Heat Treat Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What are the examples of cold working metals? Key Processes for Stronger, Precision Parts

- Why use KBr to make the pellet? Achieve Clear, Accurate IR Spectroscopy Results

- What is the detailed procedure for preparing a KBr pellet for analysis? Master the Art of Clear Spectroscopic Pellets

- Why is KBr inactive in IR? The Key to Transparent Sample Analysis

- What is the pellet technique used in IR for? Creating Clear, Transparent Samples for Accurate Analysis