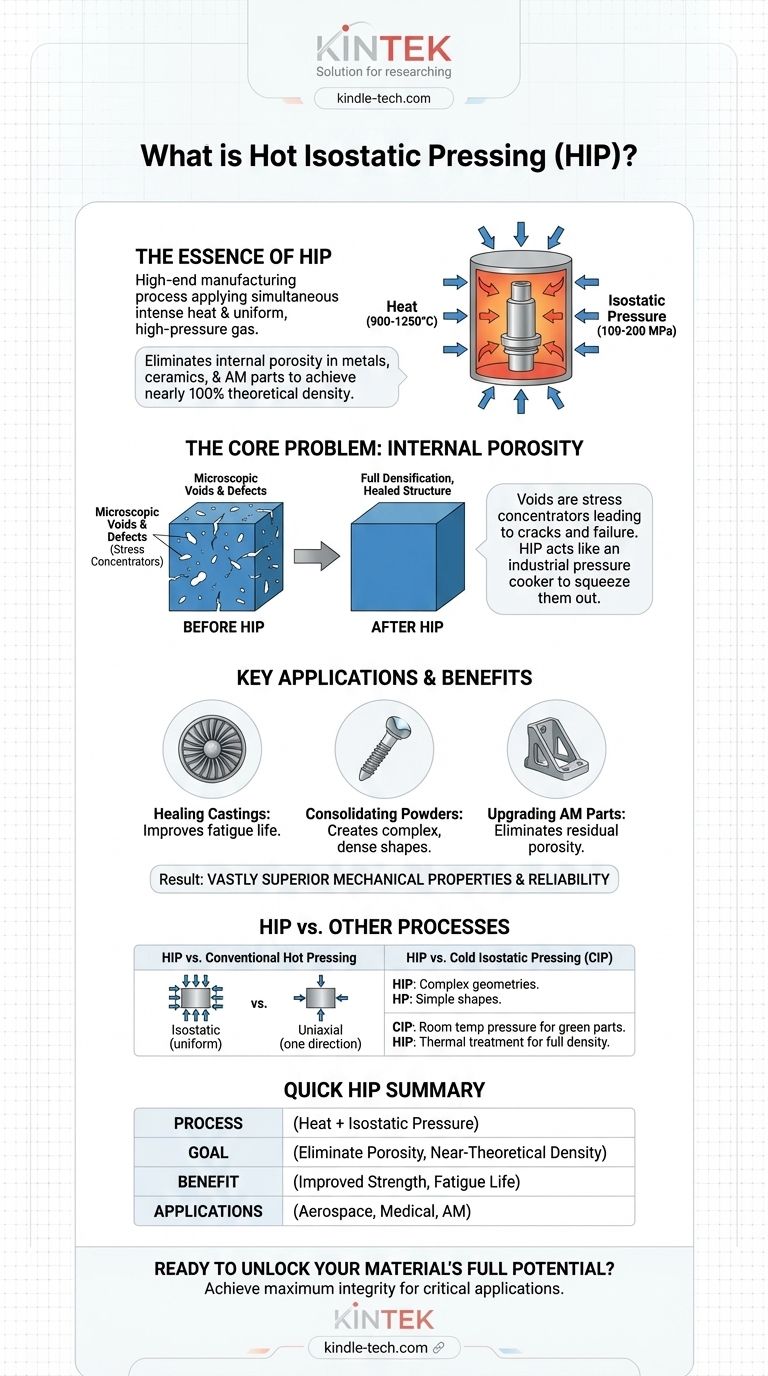

In essence, Hot Isostatic Pressing (HIP) is a high-end manufacturing process that simultaneously applies intense heat and uniform, high-pressure gas to a material. This combination eliminates internal porosity and defects within metals, ceramics, or additively manufactured parts, increasing their density to nearly 100% of their theoretical maximum. The result is a component with vastly superior mechanical properties and reliability.

The core purpose of Hot Isostatic Pressing is not to create a shape, but to perfect a material's internal structure. It acts as an industrial pressure cooker, using extreme temperature and isostatic pressure to squeeze out microscopic voids, dramatically improving the material's strength, fatigue life, and overall integrity.

The Core Problem HIP Solves: Internal Porosity

Why Voids Are the Enemy

In many advanced manufacturing processes like casting, powder metallurgy, or even 3D printing, microscopic voids or pores can become trapped within the final part. These defects are invisible to the naked eye but act as stress concentrators, becoming the initial points for cracks and eventual material failure under load.

The HIP Mechanism: Heat and Uniform Pressure

The HIP process places a component inside a high-pressure containment vessel. The vessel is heated to a temperature high enough to make the material somewhat plastic, typically between 900°C and 1250°C for steels and superalloys.

Simultaneously, the vessel is filled with a high-pressure inert gas, like argon, creating pressures of 100-200 MPa (15,000-30,000 psi). This pressure is isostatic, meaning it acts uniformly on the part from all directions.

The Result: 100% Theoretical Density

The combination of high temperature and isostatic pressure causes the material to deform on a microscopic level, collapsing the internal voids. This process effectively welds the material together from the inside out, removing the defects that compromise performance and achieving full densification.

Key Applications Across High-Performance Industries

Healing Defects in Castings

For critical cast components, such as aerospace turbine blades or engine blocks, HIP is used as a post-processing step. It closes the micro-shrinkage porosity that is inherent to the casting process, significantly improving the fatigue life and durability of these high-value parts.

Consolidating Powder Metals and Ceramics

HIP can consolidate metal or ceramic powders directly into a solid, fully dense component. The powders are sealed in a flexible mold that is subjected to the HIP cycle, creating a complex, near-net shape part with properties often superior to those made by traditional methods.

Upgrading Additively Manufactured Parts

Metal 3D printing (additive manufacturing) is revolutionary, but parts often contain residual porosity that makes them unsuitable for critical applications. HIP is a crucial final step to eliminate these voids, making 3D-printed parts strong enough for use in aerospace, medical implants, and defense systems.

Understanding the Trade-offs and Limitations

HIP vs. Conventional Hot Pressing

Traditional hot pressing applies pressure in only one direction (uniaxially), which is suitable for producing simple shapes like billets. HIP, with its isostatic pressure, can produce parts with far more complex geometries.

HIP vs. Cold Isostatic Pressing (CIP)

These are not competing processes but are often used in sequence. CIP uses pressure at room temperature to compact powders into a preliminary, fragile "green" part. HIP is then used as a thermal treatment to fully densify that part.

The Constraint of Dimensional Tolerance

While HIP can produce complex "near-net" shapes that are close to the final dimensions, it does not offer perfect dimensional accuracy due to the use of a flexible mold. For components requiring very tight tolerances, final machining is almost always necessary.

Making the Right Choice for Your Goal

By understanding its core function, you can determine when to specify the HIP process for your project.

- If your primary focus is maximum material integrity and reliability: HIP is essential for critical components in aerospace, medical, or energy sectors where failure is not an option.

- If you are working with powder metallurgy or metal additive manufacturing: HIP should be considered the default standard for achieving full densification and unlocking the material's peak performance potential.

- If your goal is to improve the yield of high-value castings: HIP is a proven method for healing internal defects, salvaging parts that might otherwise be rejected due to porosity.

By viewing Hot Isostatic Pressing as a tool for achieving internal perfection, you can specify materials and processes that meet the most demanding performance requirements.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Simultaneous application of high heat and high isostatic gas pressure. |

| Primary Goal | Eliminate internal porosity and defects to achieve near-theoretical density. |

| Key Benefit | Dramatically improved mechanical properties (strength, fatigue life). |

| Common Applications | Aerospace components, medical implants, high-performance castings, additive manufacturing. |

Ready to unlock the full potential of your materials?

If you are developing high-performance components for aerospace, medical, or energy applications, achieving maximum material density and reliability is non-negotiable. The Hot Isostatic Pressing process is key to eliminating the internal defects that compromise performance.

KINTEK specializes in providing advanced lab equipment and consumables to support your R&D and production needs. Whether you are working with metal powders, ceramics, or additively manufactured parts, we have the solutions to help you achieve superior material integrity.

Contact our experts today to discuss how HIP technology can enhance your projects and ensure your components meet the most demanding standards.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What role does Hot Isostatic Pressing (HIP) equipment play in Ti6Al4V-SiCf preparation? Achieve Peak Composite Density

- What is the sinter HIP process? Achieve Near-Perfect Density in a Single Cycle

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What are the advantages of HIP over conventional PM? Achieve Full Density for Superior Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is the pressure of hot isostatic pressing? Unlock Full Material Density with High-Pressure HIP

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What is the application of HIP? Eliminate Porosity for Superior Material Performance