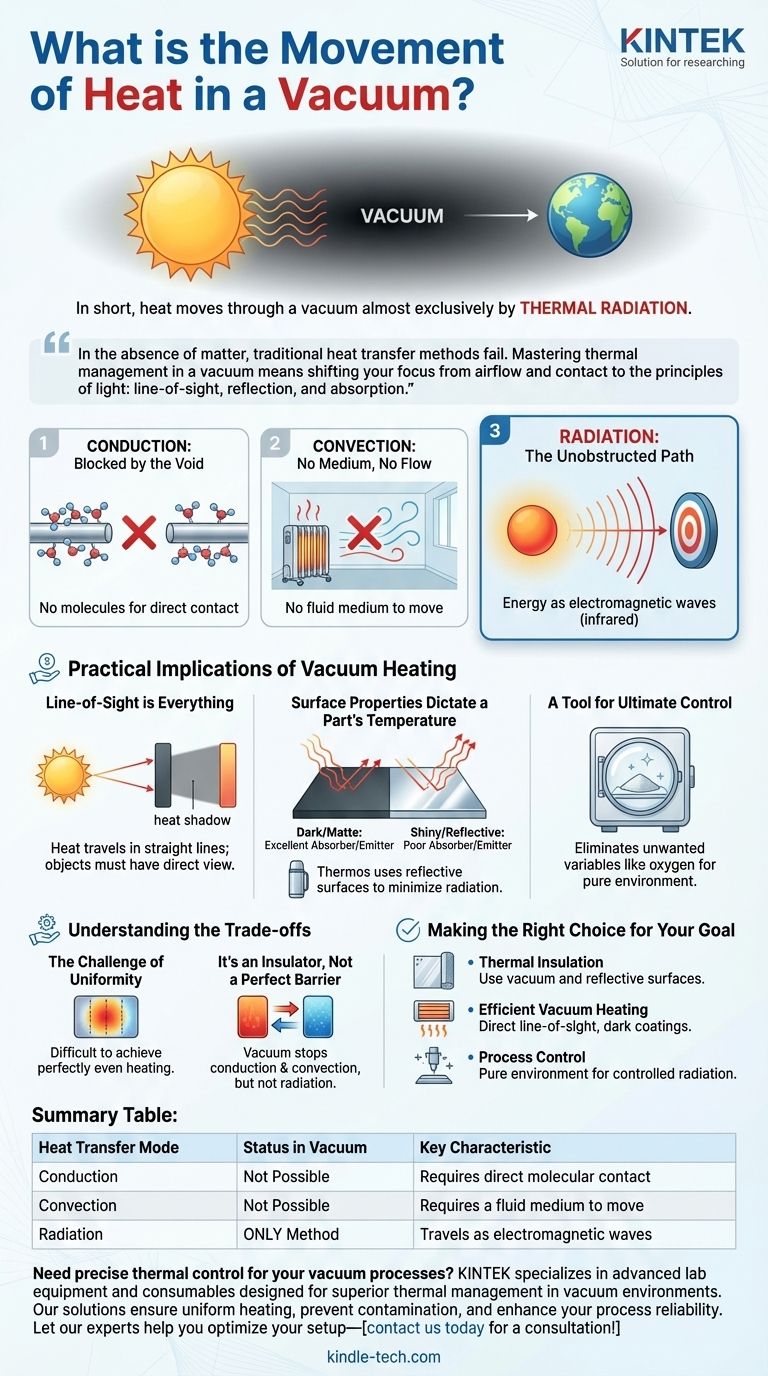

In short, heat moves through a vacuum almost exclusively by thermal radiation. Unlike conduction or convection, which require a medium of particles to transfer energy, radiation is the movement of energy as electromagnetic waves, primarily in the infrared spectrum. This is the same principle by which the Sun heats the Earth across the vast emptiness of space.

In the absence of matter, traditional heat transfer methods fail. Mastering thermal management in a vacuum means shifting your focus from airflow and contact to the principles of light: line-of-sight, reflection, and absorption.

The Three Modes of Heat Transfer

To understand why a vacuum is so different, it's essential to quickly review the three fundamental ways heat moves. In a normal, air-filled environment, all three work together. In a vacuum, two are eliminated.

Conduction: Blocked by the Void

Conduction is heat transfer through direct contact, where vibrating molecules pass energy to their neighbors. Think of a metal spoon heating up in a hot cup of coffee.

In a perfect vacuum, there are no molecules to form this chain, so conduction cannot occur.

Convection: No Medium, No Flow

Convection is heat transfer through the movement of fluids (liquids or gases). Hot air rising from a heater is a classic example of convection, as the less dense hot air moves and distributes warmth throughout a room.

A vacuum, by definition, has no air or fluid to move. Therefore, convection is also impossible.

Radiation: The Unobstructed Path

Radiation is energy emitted from all matter in the form of electromagnetic waves. This is the only form of heat transfer that does not require a medium.

Every object with a temperature above absolute zero radiates thermal energy. In a vacuum, these waves travel unimpeded until they strike an object, where they are either absorbed, reflected, or transmitted. The absorbed energy excites the object's molecules, increasing its temperature.

Practical Implications of Vacuum Heating

Understanding that radiation is the only game in town has critical consequences for any process that involves heating or cooling in a vacuum, such as in industrial furnaces or space applications.

"Line-of-Sight" is Everything

Because heat travels in straight lines like light, an object can only be heated if it has a direct, unobstructed view of the heat source.

If another part is in the way, it will cast a "heat shadow." This is why workpieces in a vacuum furnace must be carefully spaced apart to ensure all surfaces are exposed to the heating elements for uniform heating.

Surface Properties Dictate a Part's Temperature

An object's ability to absorb or emit radiative heat is determined by its surface.

- Dark, matte surfaces are excellent absorbers and emitters of radiation.

- Shiny, reflective surfaces are poor absorbers and emitters.

This is why a thermos, or vacuum flask, has silvered internal surfaces. The vacuum stops conduction and convection, while the reflective surfaces minimize heat loss (or gain) from radiation.

A Tool for Ultimate Control

Using a vacuum is a powerful tool in industrial processes like heat treatment. By removing air, you eliminate unwanted variables like oxygen, which prevents oxidation and other chemical reactions on the material's surface.

This provides a clean, highly controlled environment where the only major interaction is the carefully managed application of radiative heat.

Understanding the Trade-offs

While powerful, designing for a vacuum environment presents unique challenges.

The Challenge of Uniformity

Achieving perfectly even heating is difficult. It requires strategic placement of multiple heating elements and careful arrangement of the parts to avoid the "heat shadow" effect.

It's an Insulator, Not a Perfect Barrier

A vacuum is an exceptional insulator against conduction and convection, but it does not stop radiation. Any two objects in a vacuum that can "see" each other will exchange heat. A hot object will radiate heat to a cold object, and the cold object will cool the hot one.

Misconceptions About Heat Transfer

Some industrial systems use a vacuum to lower the boiling point of a liquid like water, then use the resulting steam to heat something. While this process uses a vacuum, the final heat transfer is done by the steam (convection and condensation), not radiation through the vacuum itself.

Making the Right Choice for Your Goal

Your strategy depends entirely on whether you want to move heat or stop it.

- If your primary focus is thermal insulation: Create a vacuum to stop conduction and convection, and use highly reflective surfaces (like polished metal) to block thermal radiation.

- If your primary focus is efficient vacuum heating: Arrange heating elements to provide a direct line-of-sight to all surfaces of your object, and use dark, matte coatings if you need to maximize heat absorption.

- If your primary focus is process control: Use the vacuum to create a pure environment, free from atmospheric contamination, allowing for precise surface treatments via controlled radiation.

Ultimately, mastering thermal dynamics in a vacuum is about learning to think of heat not as a pervasive fluid, but as rays of light.

Summary Table:

| Heat Transfer Mode | Status in Vacuum | Key Characteristic |

|---|---|---|

| Conduction | Not Possible | Requires direct molecular contact. |

| Convection | Not Possible | Requires a fluid medium to move. |

| Radiation | ONLY Method | Travels as electromagnetic waves. |

Need precise thermal control for your vacuum processes? KINTEK specializes in advanced lab equipment and consumables designed for superior thermal management in vacuum environments. Our solutions ensure uniform heating, prevent contamination, and enhance your process reliability. Let our experts help you optimize your setup—contact us today for a consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vertical Laboratory Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing