At its core, Spark Plasma Sintering (SPS) is an advanced powder consolidation technique that uses simultaneous uniaxial pressure and a pulsed direct electrical current to transform loose powder into a dense, solid material. This process occurs at an exceptionally rapid rate, achieving full densification in minutes rather than the hours required by conventional methods.

Spark Plasma Sintering is not merely a faster way to heat material. It is a fundamentally different approach that uses an electric field to activate powder particles directly, enabling densification at lower temperatures and with greater speed, thereby preserving fine-grained microstructures that are critical for high-performance materials.

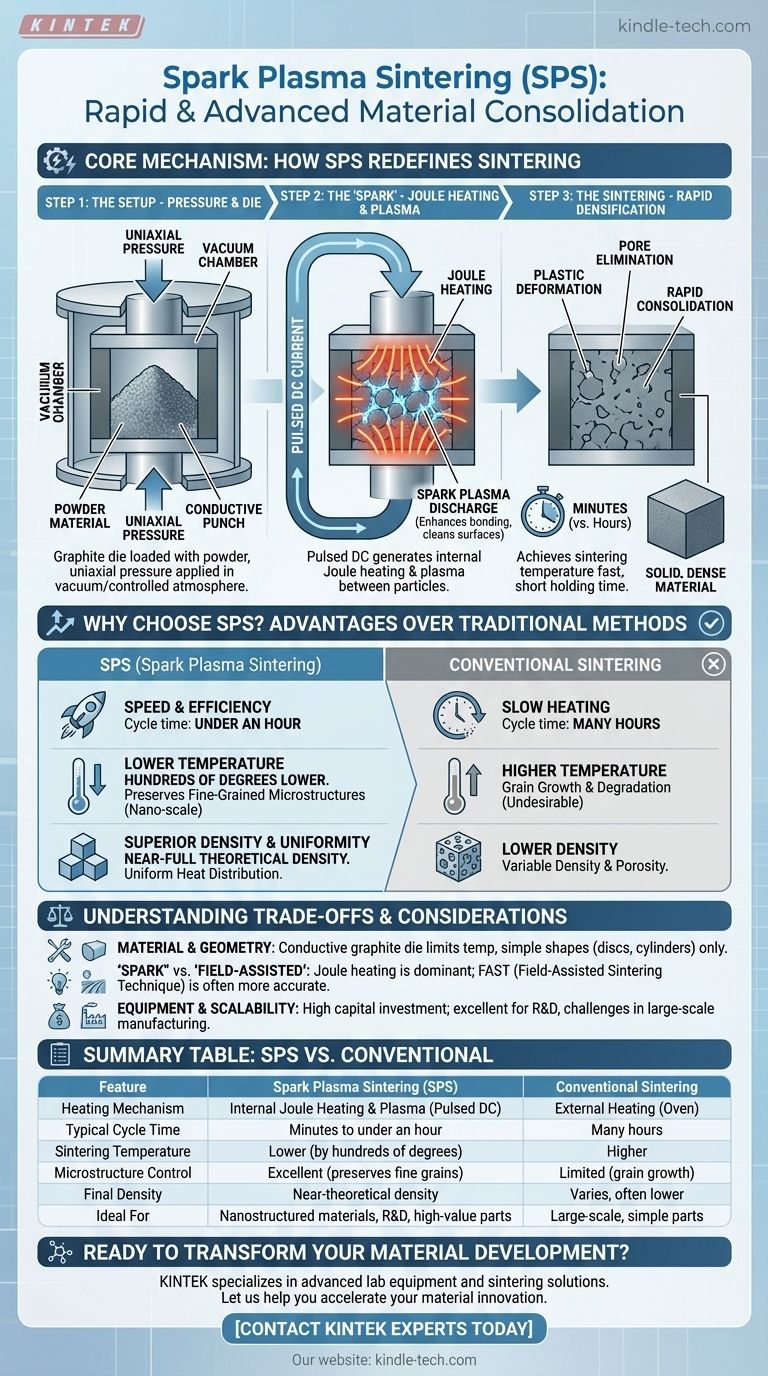

How SPS Redefines Sintering: The Core Mechanism

Traditional sintering is like a conventional oven; it slowly heats a material from the outside in. SPS, also known as Field-Assisted Sintering Technique (FAST), is more like a combination of a hydraulic press and a targeted internal heating system.

Step 1: The Setup - Pressure and a Die

The process begins by loading the powder material into a conductive die, which is almost always made of graphite. This die is then placed between two punches inside a vacuum chamber.

A uniaxial mechanical pressure is applied through the punches, compacting the loose powder. The chamber is evacuated to create a vacuum or filled with a controlled atmosphere to prevent oxidation and contamination.

Step 2: The "Spark" - Joule Heating and Plasma

Once the pressure and atmosphere are set, a high-amperage, pulsed direct current (DC) is passed through the punches and the graphite die. This current is the key to the entire process and generates intense heat through two primary effects.

The dominant effect is Joule heating. The electrical resistance of the graphite die and, if conductive, the sample powder itself, generates rapid and uniform heat. This heats the sample both externally (from the die) and internally (from within the powder).

A secondary effect, which gives the method its name, is the generation of spark plasma discharge in the voids between powder particles. This momentary plasma helps clean particle surfaces of oxides and impurities, which enhances bonding.

Step 3: The Sintering - Rapid Densification

The combination of intense, uniform heat and constant mechanical pressure causes the powder particles to undergo plastic deformation. The particles bond at their contact points, and the pores between them are eliminated.

Because the heating rates can be as high as 1000°C/min, the material reaches its sintering temperature almost instantly. This allows the entire densification process to be completed in a very short holding time, often just a few minutes.

Why Choose SPS? Key Advantages Over Traditional Methods

SPS offers distinct advantages that make it the preferred method for producing advanced ceramics, composites, and novel alloys.

Unprecedented Speed and Efficiency

The most significant advantage of SPS is its speed. By eliminating the long heating, soaking, and cooling times of conventional furnaces, SPS drastically shortens the production cycle from many hours to under an hour.

Lower Temperature, Better Microstructure

SPS typically achieves full densification at temperatures several hundred degrees lower than conventional sintering. This is critical because high temperatures and long exposure times cause undesirable grain growth, which can degrade a material's mechanical properties.

By minimizing both temperature and time, SPS is exceptional at producing nanostructured or fine-grained materials, preserving the unique properties that come from these small-scale features.

Superior Density and Uniformity

The combination of internal Joule heating and external heating from the die ensures a highly uniform temperature distribution throughout the sample. This, coupled with the applied pressure, effectively eliminates porosity and consistently produces materials with near-full theoretical density.

Understanding the Trade-offs and Considerations

While powerful, SPS is not a universal solution. Understanding its limitations is key to using it effectively.

Material and Geometry Limitations

The standard SPS process relies on a conductive graphite die, which limits the maximum processing temperature and can cause carbon contamination in sensitive materials. Furthermore, the uniaxial pressure setup restricts sample geometries to relatively simple shapes like discs, cylinders, and squares.

The "Spark" vs. "Field-Assisted" Distinction

While "Spark Plasma Sintering" is the common name, many experts prefer the more accurate term Field-Assisted Sintering Technique (FAST). This is because research indicates that Joule heating is the dominant mechanism, and a sustained plasma is not always present or necessary for densification.

Equipment and Scalability

SPS systems are specialized and represent a significant capital investment compared to conventional furnaces. While excellent for research, development, and high-value component production, scaling the process for very large parts or high-volume manufacturing remains a challenge.

Making the Right Choice for Your Application

Deciding whether to use SPS depends entirely on your material and performance goals.

- If your primary focus is rapid prototyping and developing novel materials: SPS is an unparalleled tool, as its speed allows for quick iteration and experimentation.

- If your primary focus is preserving nano-scale or fine-grained microstructures: SPS is the superior choice, as its low temperature and short duration prevent the grain growth common in other methods.

- If your primary focus is creating materials with the highest possible density: SPS excels at eliminating porosity and achieving near-theoretical density, especially for difficult-to-sinter materials.

- If your primary focus is producing large, geometrically complex parts at low cost: Traditional methods like casting or conventional press-and-sinter routes are likely more suitable.

SPS is a transformative technology that empowers the creation of next-generation materials by offering precise control over the densification process.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Heating Mechanism | Internal Joule Heating & Plasma (Pulsed DC) | External Heating (Oven) |

| Typical Cycle Time | Minutes to under an hour | Many hours |

| Sintering Temperature | Lower (by hundreds of degrees) | Higher |

| Microstructure Control | Excellent (preserves fine grains) | Limited (grain growth) |

| Final Density | Near-theoretical density | Varies, often lower |

| Ideal For | Nanostructured materials, R&D, high-value parts | Large-scale, simple parts |

Ready to Transform Your Material Development with SPS?

Spark Plasma Sintering is the key to unlocking the potential of advanced ceramics, composites, and novel alloys. If your research or production demands rapid prototyping, preservation of fine-grained microstructures, or achieving near-theoretical density, the right equipment is critical.

KINTEK specializes in advanced lab equipment, including sintering solutions, to meet the precise needs of laboratories and research facilities.

Let us help you accelerate your material innovation. Contact our experts today to discuss how SPS technology can benefit your specific application.

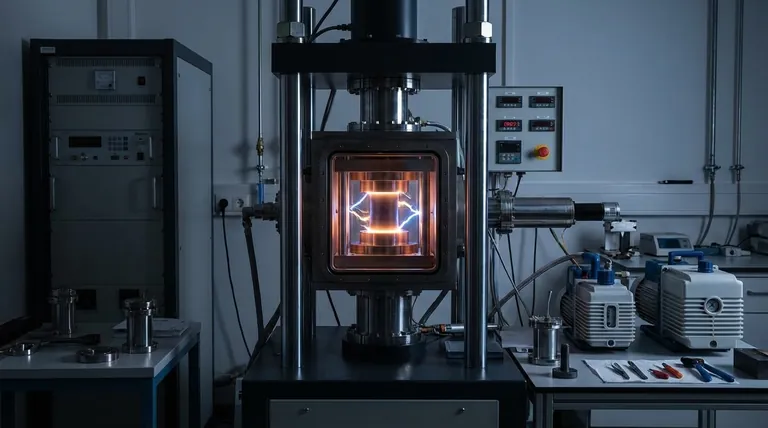

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is spark plasma sintering process? Fast-Track to Dense, Fine-Grained Materials

- What is spark plasma sintering of polymers? Rapidly Create Dense, High-Performance Materials

- What is the plasma sintering method? Unlock Rapid, High-Density Material Fabrication

- What are the uses of spark plasma sintering? Fast, Low-Temp Fabrication of Advanced Materials

- What is the difference between spark plasma sintering and flash sintering? A Guide to Advanced Sintering Methods