Under ideal conditions, a properly brazed joint is stronger than the base metals being joined. This means that if the assembly is subjected to enough stress to cause a failure, the base metal itself will break before the joint does. The strength is not inherent in the filler metal alone but is a result of correct design and procedure.

The question is not how strong the brazing filler metal is, but how the design of the joint leverages that filler to create an assembly whose strength is limited only by the parent materials themselves.

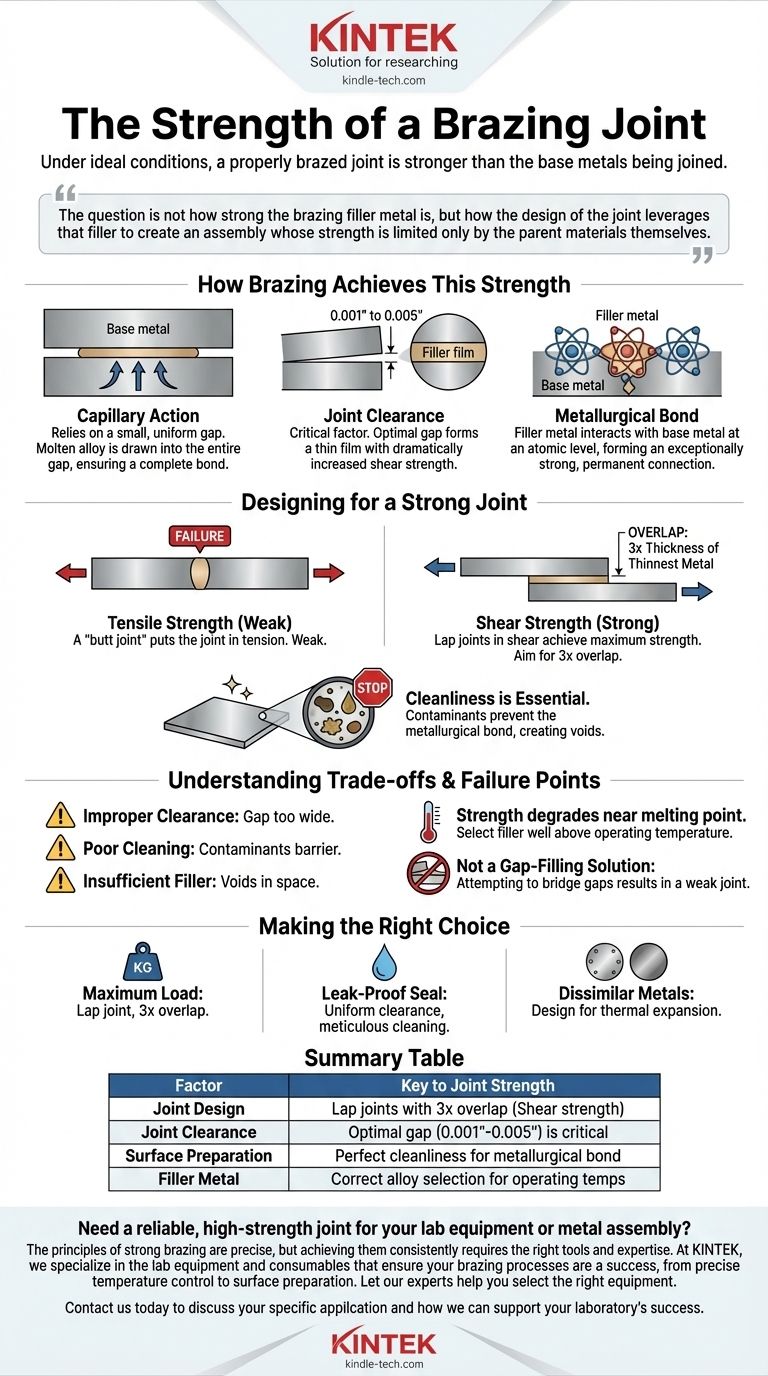

How Brazing Achieves This Strength

The remarkable strength of a brazed joint comes from a combination of metallurgical principles and mechanical design. It is not simply a matter of gluing two pieces of metal together.

The Role of Capillary Action

A brazed joint relies on a very small, uniform gap between the two base metal parts. When the filler metal is introduced, capillary action draws the molten alloy into this entire gap, ensuring a complete and consistent bond across the mating surfaces.

The Principle of Joint Clearance

The distance between the parts being joined, known as joint clearance, is the single most critical factor in determining strength. If the gap is too wide, the joint's strength will be limited to the inherent strength of the filler metal, which is significantly weaker than the base metal.

If the gap is in the optimal range (typically 0.001" to 0.005"), the filler metal forms a thin film that is metallurgically bonded to both surfaces. This configuration constrains the filler metal, dramatically increasing its shear strength.

Creating a Metallurgical Bond

Brazing creates a true metallurgical bond. The filler metal doesn't just stick to the base metal; it interacts with it on an atomic level. It dissolves a microscopic amount of the base metal, forming an exceptionally strong, permanent connection as it cools and solidifies.

Designing for a Strong Joint

The assertion that a brazed joint is stronger than the parent metal is entirely conditional on proper design. A poorly designed joint will always be a point of failure.

Shear Strength over Tensile Strength

Brazed joints are exceptionally strong in shear and relatively weak in tension. A "butt joint" (pulling directly apart) puts the joint in tension. A "lap joint" (where the surfaces overlap) puts the joint in shear.

To achieve maximum strength, joints should always be designed as lap joints. A good rule of thumb is to create an overlap of at least three times the thickness of the thinnest metal being joined. This ensures the total strength of the brazed area exceeds the strength of the base metal.

The Importance of Cleanliness

The metallurgical bond can only form on a perfectly clean surface. Any contaminants—such as oils, grease, or oxides—will act as a barrier, preventing the filler metal from bonding with the base metal. This will create voids and dramatically reduce the strength and integrity of the joint.

Understanding the Trade-offs and Failure Points

While incredibly effective, brazing has specific conditions that must be respected for a successful outcome. Understanding why a joint might fail is key to preventing it.

Common Causes of Joint Failure

When a brazed joint fails at the joint, it is almost always due to a violation of proper procedure. The primary culprits are:

- Improper Joint Clearance: Too wide a gap prevents the filler metal from achieving its maximum strength.

- Poor Cleaning: Contaminants prevent the formation of a metallurgical bond.

- Insufficient Filler Metal: Not enough filler was used to completely fill the capillary space.

Temperature Limitations

The strength of a brazed joint degrades as the service temperature approaches the melting point of the filler alloy. You must select a filler metal with a melting temperature well above the intended operating temperature of the assembly.

Not a Gap-Filling Solution

Unlike welding, brazing cannot be used to fill large or inconsistent gaps. The process depends entirely on the principle of capillary action within a tight, uniform space. Attempting to bridge gaps will result in a weak joint with the strength of only the cast filler alloy.

Making the Right Choice for Your Goal

Achieving a joint stronger than the parent metal requires designing the joint specifically for the brazing process.

- If your primary focus is maximum load-bearing capacity: Design a lap joint with an overlap of at least 3x the thickness of the thinnest member to ensure failure occurs in the base metal, not the joint.

- If your primary focus is creating a leak-proof seal: Prioritize a uniform joint clearance and meticulous cleaning to guarantee complete capillary fill with no voids.

- If your primary focus is joining dissimilar metals: Brazing is an ideal choice, but you must design the joint to accommodate different rates of thermal expansion to avoid stress during the heating and cooling cycle.

By focusing on meticulous joint design, you can reliably create a brazed assembly where the joint is the strongest part of the structure.

Summary Table:

| Factor | Key to Joint Strength |

|---|---|

| Joint Design | Lap joints with 3x overlap are strongest (shear strength). |

| Joint Clearance | Optimal gap (0.001"-0.005") is critical for capillary action. |

| Surface Preparation | Perfect cleanliness is essential for a metallurgical bond. |

| Filler Metal | Correct alloy selection ensures strength at operating temperatures. |

Need a reliable, high-strength joint for your lab equipment or metal assembly?

The principles of strong brazing are precise, but achieving them consistently requires the right tools and expertise. At KINTEK, we specialize in the lab equipment and consumables that ensure your brazing processes are a success, from precise temperature control to surface preparation.

Let our experts help you select the right equipment to achieve joints stronger than the parent metal. Contact us today to discuss your specific application and how we can support your laboratory's success.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- Is sintering the same as hot press? Unlock the Key Differences for Better Material Performance

- What is the hot pressing method of sintering? A Guide to High-Density Material Fabrication

- What is pressure-assisted sintering? Achieve Denser, Stronger Materials Faster

- What is vacuum hot pressing? Achieve Maximum Density & Purity in Advanced Materials