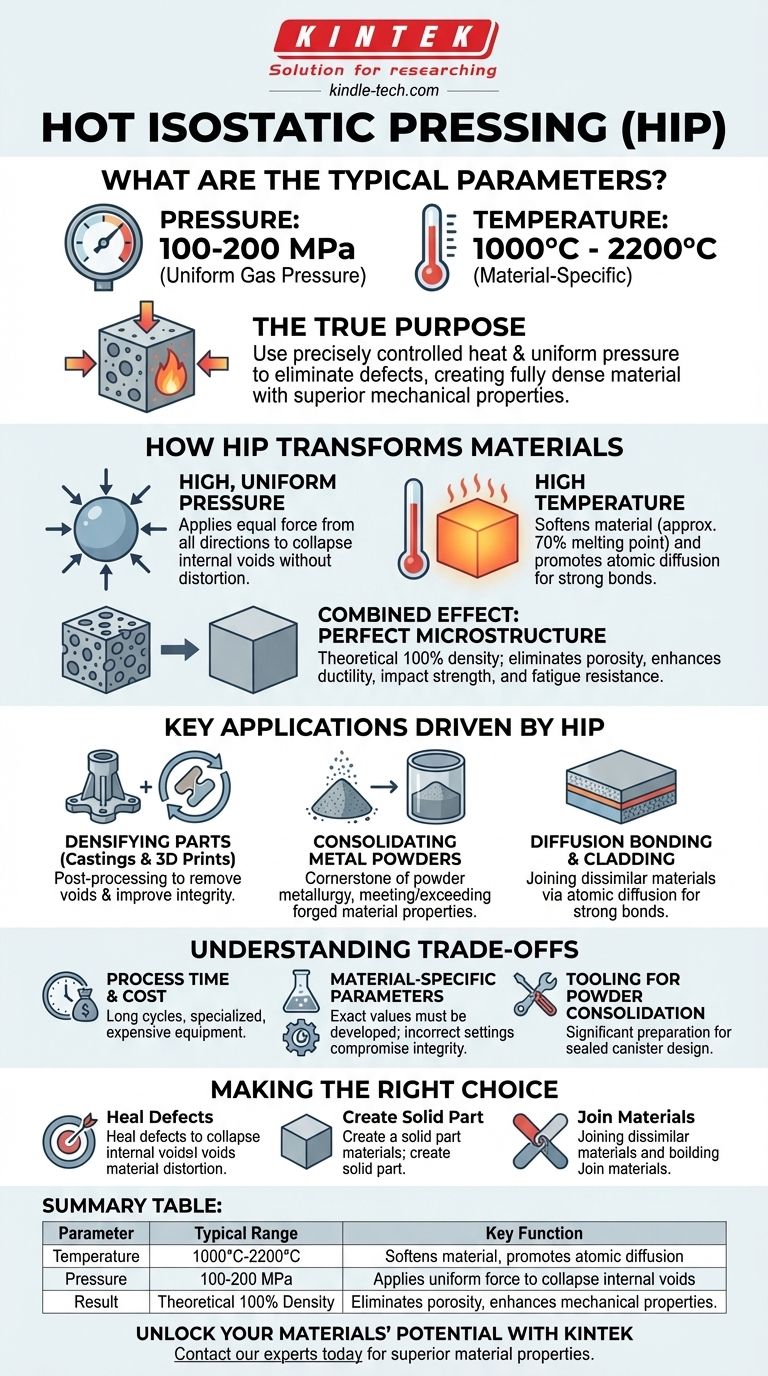

The typical parameters for hot isostatic pressing (HIP) involve applying a uniform gas pressure of 100 to 200 MPa at a high temperature, generally between 1000°C and 2200°C. The exact values are carefully selected based on the specific material being processed and the desired final properties.

The specific numbers for temperature and pressure are only part of the story. The true purpose of HIP is to use a precisely controlled combination of heat and uniform pressure to eliminate internal defects, creating a fully dense material with superior mechanical properties that are often impossible to achieve through other means.

How HIP Transforms Materials

Hot isostatic pressing is not simply a heating and squeezing process; it is a sophisticated method of material consolidation that fundamentally alters a component at the microscopic level.

The Role of High, Uniform Pressure

The "isostatic" part of the name is critical. An inert gas, typically argon, is used to apply pressure equally from all directions within a sealed, high-pressure chamber.

This uniform pressure collapses any internal voids, pores, or microscopic cracks within a material without distorting the part's overall shape.

The Role of High Temperature

Heat is the enabler. By raising the temperature to a significant fraction of the material's melting point (often around 70% of its melting temperature), the material's yield strength is drastically lowered.

This softening allows the gas pressure to effectively close the internal defects. High temperature also promotes atomic diffusion, allowing material to move and form strong metallurgical bonds where the voids once were.

The Combined Effect: A Perfect Microstructure

When high pressure and high temperature are applied simultaneously, the result is a component that is theoretically 100% dense.

This process eliminates the internal porosity that plagues castings and some 3D-printed parts, resulting in a uniform, fine-grained microstructure. This directly enhances properties like ductility, impact strength, and fatigue resistance.

Key Applications Driven by HIP

The unique ability of HIP to heal internal defects drives its use in high-performance industries where material failure is not an option.

Densifying Castings and 3D Printed Parts

Components produced by casting or additive manufacturing (3D printing) often contain residual porosity. HIP is used as a post-processing step to remove these voids, significantly improving the fatigue life and mechanical integrity of the final part.

Consolidating Metal Powders

HIP is a cornerstone of modern powder metallurgy. In this application, spherical metal powder is sealed in a metallic container or "can," which is evacuated of air and sealed.

The HIP cycle consolidates the powder into a fully dense, solid part with properties that can meet or exceed those of traditionally forged or wrought materials.

Diffusion Bonding and Cladding

The process can also be used to join dissimilar materials. By placing two different materials in contact under HIP conditions, atoms can diffuse across the boundary, creating a strong, continuous bond without melting. This is also used for cladding a base material with a high-performance alloy.

Understanding the Trade-offs

While powerful, HIP is a specialized process with important considerations. It is not a universal solution for all manufacturing challenges.

Process Time and Cost

HIP cycles are long, often lasting several hours. The equipment is also highly specialized and expensive to operate. This makes HIP a premium process reserved for applications where its benefits justify the cost.

Material-Specific Parameters

The temperature and pressure ranges provided are general guidelines. The exact parameters must be carefully developed for each specific alloy. An incorrect temperature can lead to undesirable grain growth or even partial melting, compromising the component's integrity.

Tooling for Powder Consolidation

When used for powder metallurgy, a significant amount of preparation is required to design and fabricate the sealed canister that holds the powder and defines the part's near-net shape.

Making the Right Choice for Your Goal

The optimal HIP parameters are defined by your specific objective.

- If your primary focus is healing defects in existing parts (castings, 3D prints): You will use parameters designed to close internal porosity without altering the part's net shape.

- If your primary focus is creating a solid part from powder: Your process will involve encapsulating the powder and selecting a temperature that enables full densification and atomic bonding.

- If your primary focus is joining different materials: The parameters must be carefully engineered to facilitate atomic diffusion across the material interface without causing unwanted melting or reactions.

Ultimately, understanding the interplay between temperature, pressure, and material science is the key to leveraging the full power of hot isostatic pressing.

Summary Table:

| Parameter | Typical Range | Key Function |

|---|---|---|

| Temperature | 1000°C - 2200°C | Softens material, promotes atomic diffusion |

| Pressure | 100 MPa - 200 MPa | Applies uniform force to collapse internal voids |

| Result | Theoretical 100% Density | Eliminates porosity, enhances mechanical properties |

Ready to unlock the full potential of your materials with Hot Isostatic Pressing?

KINTEK specializes in advanced lab equipment and consumables for materials science. Whether you are densifying castings, consolidating metal powders, or exploring diffusion bonding, our expertise and solutions can help you achieve superior material properties and performance.

Contact our experts today to discuss how HIP can solve your specific material challenges and enhance your R&D or production outcomes.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Cylindrical Press Mold with Scale for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is the hot isostatic process? Achieve Perfect Material Density for Critical Components

- How do warm isostatic presses improve dry electrode performance? Enhance ASSB Conductivity with Heat & Pressure

- What is the purpose of using 160 MPa pressure in HIP for Inconel 718? Achieve Aerospace-Grade Alloy Density

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What is the working principle of hot isostatic pressing? Unlock Superior Material Density & Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What is the hot isostatic pressing cycle? A Guide to HIP for Superior Material Integrity

- What is the HIP sintering process? Achieve Near-Perfect Densification for Critical Components