Technically, there is no single upper temperature limit for brazing. Instead, brazing is defined by its lower temperature boundary of 450°C (840°F). The actual temperature used is determined by the specific filler metal, while the practical upper limit is always set by the melting point of the base materials you are joining.

The critical temperature in brazing isn't a single number, but a carefully controlled window. You must operate above the melting point of your filler metal but safely below the melting point of your base materials. This fundamental principle is what defines the process and separates it from both soldering and welding.

The Defining Line: Brazing vs. Soldering vs. Welding

To understand the temperature limits of brazing, you must first understand its place among other joining processes. The temperature is the primary distinction.

The 450°C (840°F) Threshold

The American Welding Society officially defines brazing as any process that joins materials using a filler metal that melts and flows above 450°C (840°F).

Any similar process that occurs below this temperature is defined as soldering. This single temperature is the globally accepted dividing line between the two.

Brazing's Core Principle: Capillary Action

In a proper brazing operation, only the filler metal melts. The base materials being joined are heated, but they never reach their melting point.

The molten filler is drawn into the tight-fitting gap between the parts through a phenomenon called capillary action. This creates a strong, metallurgically bonded joint without fusing the base materials.

Why Welding Is Different

Welding, by contrast, works by melting the base materials themselves, often along with a filler metal, to fuse them into a single, continuous piece.

Because it involves melting the base materials, welding always occurs at significantly higher temperatures than brazing for any given metal.

Finding Your Brazing Temperature Window

The "correct" brazing temperature is not one number, but a specific range dictated by your materials.

The Role of the Filler Metal

Every brazing filler metal has a melting range defined by two points: its solidus (the temperature at which it begins to melt) and its liquidus (the temperature at which it is fully liquid).

To ensure proper flow and capillary action, the base materials must be heated to a temperature above the filler metal's liquidus point. For most fillers, this is typically 30-60°C (50-100°F) above the liquidus temperature.

The Constraint of the Base Material

The absolute upper limit for your brazing temperature is the solidus of the weakest base material in the assembly.

If you exceed this temperature, you will begin to melt the part itself. The process ceases to be brazing and becomes welding or, more accurately, a failure. This can cause irreversible damage, distortion, and a weak joint.

The "Brazing Range" in Practice

Your working temperature window is therefore the range between the filler metal's liquidus and the base material's solidus.

For example, joining steel (melts ~1370°C) with a silver-based filler (liquidus ~650°C) gives you a massive working window. Joining aluminum parts (melts ~600°C) with an aluminum-silicon filler (liquidus ~585°C) requires extremely precise temperature control.

Understanding the Trade-offs: Heat and Its Consequences

The high temperatures of brazing, even when below the base metal's melting point, have significant effects you must manage.

The Heat-Affected Zone (HAZ)

The area of the base material near the joint is heated and then cooled. This thermal cycle creates a heat-affected zone (HAZ).

Within the HAZ, the metal's microstructure and mechanical properties (like hardness and strength) can be altered. This is a critical consideration for heat-treated or work-hardened alloys.

Risk of Distortion and Warping

Heating metal causes it to expand, and cooling causes it to contract. Uneven or excessive heating can cause parts to warp or distort, especially on thin or complex assemblies. Lower brazing temperatures reduce this risk.

Oxidation and the Need for Flux

At brazing temperatures, most metals react rapidly with oxygen in the air, forming oxides on the surface. These oxide layers prevent the filler metal from wetting the surface and flowing into the joint.

This is why a brazing flux or a controlled, oxygen-free atmosphere (like nitrogen or a vacuum) is non-negotiable. They protect the joint area from oxidation during the heating cycle.

Making the Right Choice for Your Application

Selecting the correct process requires balancing joint requirements, material properties, and thermal effects.

- If your primary focus is maximum joint strength on thick, similar metals: Welding is often the superior choice, as it fuses the parent materials into one piece.

- If your primary focus is joining dissimilar metals, thin sections, or complex assemblies without distortion: Brazing's lower temperatures and non-fusion nature provide a significant advantage.

- If your primary focus is joining heat-sensitive electronics or standard copper plumbing: Soldering is the correct process, as its low temperatures prevent damage to components and materials.

Mastering the temperature window is the key to creating strong, reliable, and precise brazed joints.

Summary Table:

| Brazing Temperature Factor | Key Temperature Point | Description |

|---|---|---|

| Lower Limit | 450°C (840°F) | Official AWS definition separating brazing from soldering |

| Filler Metal Liquidus | Varies by alloy | Temperature at which filler metal becomes fully liquid |

| Base Material Solidus | Varies by material | Absolute upper limit to avoid melting the parts being joined |

| Working Window | Between liquidus and solidus | The safe temperature range for successful brazing |

Need precise temperature control for your brazing applications? KINTEK specializes in laboratory equipment and consumables that ensure accurate thermal processing for your joining needs. Our solutions help you maintain the critical temperature window between filler metal flow and base material integrity. Contact our experts today to discuss how we can support your laboratory's brazing and material joining requirements with reliable, precision equipment.

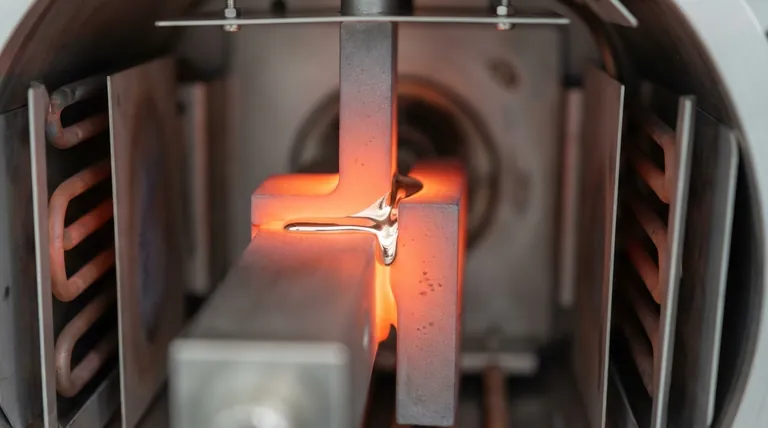

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role do high-temperature annealing furnaces play in evaluating materials after ion beam irradiation?

- Why is it necessary to process samples in a vacuum drying oven before sputtering? Ensure Coating Purity and Adhesion

- Why must high-vacuum annealing furnaces be used for diamond doping? Protect Crystals from Irreversible Graphitization

- Why is a high-precision heat treatment furnace essential for ceramic green bodies? Ensure Structural Integrity

- What is thin film deposition thermal evaporation? A Simple Guide to High-Vacuum Coating

- What is the purpose of using a high-temperature sintering furnace for post-annealing NASICON? Enhance Ionic Conductivity

- What role do high-temperature furnaces play in RAFM steel pretreatment? Achieve Precise Microstructural Stability

- What are the factors affecting the sintering process? Master the 5 Key Factors for Perfect Sintering