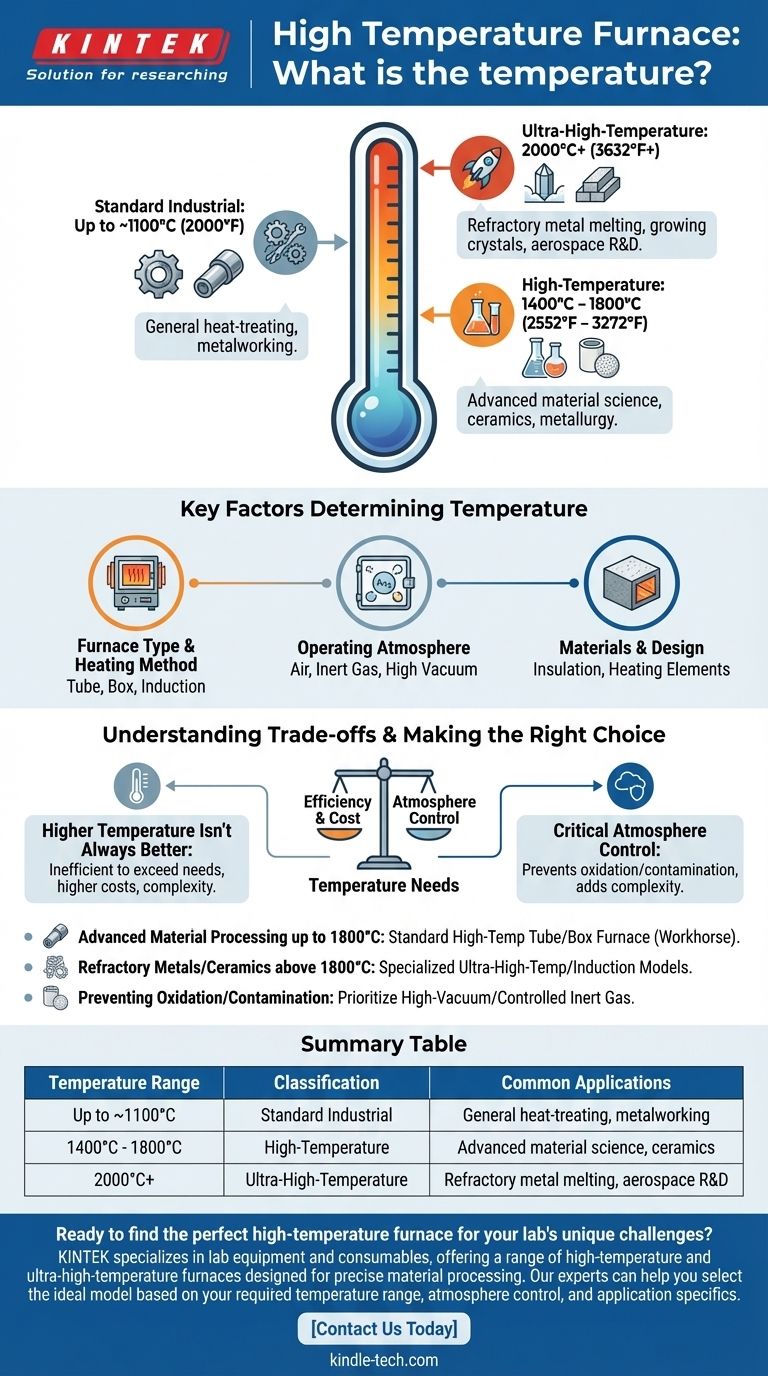

For industrial and research applications, a high-temperature furnace typically operates in the range of 1400°C to 1800°C (2552°F to 3272°F). However, specialized models known as ultra-high-temperature furnaces are engineered to exceed this, reaching up to 2000°C or even higher under precisely controlled atmospheric conditions.

The term "high temperature" is not a single value but a classification for furnaces designed for processes beyond the limits of standard equipment. The exact temperature capability is determined by the furnace's specific type, heating method, and its intended application.

Defining the "High Temperature" Threshold

Understanding what qualifies as a "high temperature" furnace requires establishing a baseline. Not all industrial furnaces are designed for the extreme conditions required in specialized material science, metallurgy, or advanced ceramics research.

The Standard Industrial Baseline

Many common industrial furnaces, such as those powered by natural gas, operate at temperatures up to approximately 1100°C (around 2000°F). This range is sufficient for many heat-treating and metalworking applications.

The High-Temperature Leap

High-temperature furnaces are specifically designed to operate reliably above this baseline. The range of 1400°C to 1800°C represents a significant engineering challenge, requiring different materials for heating elements and insulation to function without failure.

The Ultra-High-Temperature Category

For the most demanding applications, ultra-high-temperature furnaces push the limits further, reaching 2000°C and beyond. These are highly specialized instruments used for melting refractory metals, growing crystals, or testing materials for aerospace applications.

Key Factors That Determine Furnace Temperature

A furnace's maximum temperature is not an arbitrary number. It is the result of its core design, the materials used in its construction, and the environment it creates internally.

Furnace Type and Heating Method

Different designs achieve high temperatures in unique ways. Tube and box furnaces often use resistive heating elements, while induction furnaces use electromagnetic induction to heat the material directly, allowing them to reach 1800°C or more with great efficiency.

Operating Atmosphere

Temperature is only one part of the equation. Many high-temperature processes must occur in a controlled environment to prevent oxidation or contamination. Furnaces may operate in the open air, with an inert gas like argon, or under a high vacuum to protect the material being processed.

Understanding the Trade-offs

Selecting a furnace involves more than just finding the one with the highest temperature rating. The right choice depends on a careful balance of process requirements, material compatibility, and operational complexity.

Higher Temperature Isn't Always Better

Choosing a furnace that dramatically exceeds your needs is inefficient. The energy costs, material wear, and complexity of operating at 1800°C are substantially higher than at 1400°C. The goal is to match the equipment to the specific application.

The Critical Role of Atmosphere Control

A furnace that can reach 2000°C in the air is fundamentally different from one that achieves the same temperature under a high vacuum. Processes involving reactive metals or sensitive materials depend on the furnace's ability to provide a non-reactive environment, which adds significant complexity and cost.

Making the Right Choice for Your Application

To select the appropriate equipment, you must first define your primary objective.

- If your primary focus is advanced material processing up to 1800°C: A standard high-temperature tube or box furnace is the industry workhorse for these applications.

- If your primary focus is research on refractory metals or advanced ceramics above 1800°C: You will need to investigate specialized ultra-high-temperature or induction furnace models.

- If your primary focus is preventing material oxidation or contamination: Prioritize furnaces with high-vacuum or controlled inert gas capabilities suitable for your target temperature range.

Ultimately, understanding the relationship between temperature, furnace type, and atmosphere is the key to achieving precise and repeatable results.

Summary Table:

| Temperature Range | Classification | Common Applications |

|---|---|---|

| Up to ~1100°C | Standard Industrial | General heat-treating, metalworking |

| 1400°C - 1800°C | High-Temperature | Advanced material science, ceramics |

| 2000°C+ | Ultra-High-Temperature | Refractory metal melting, aerospace R&D |

Ready to find the perfect high-temperature furnace for your lab's unique challenges? KINTEK specializes in lab equipment and consumables, offering a range of high-temperature and ultra-high-temperature furnaces designed for precise material processing. Our experts can help you select the ideal model based on your required temperature range, atmosphere control, and application specifics. Contact us today to discuss your needs and enhance your lab's capabilities!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis