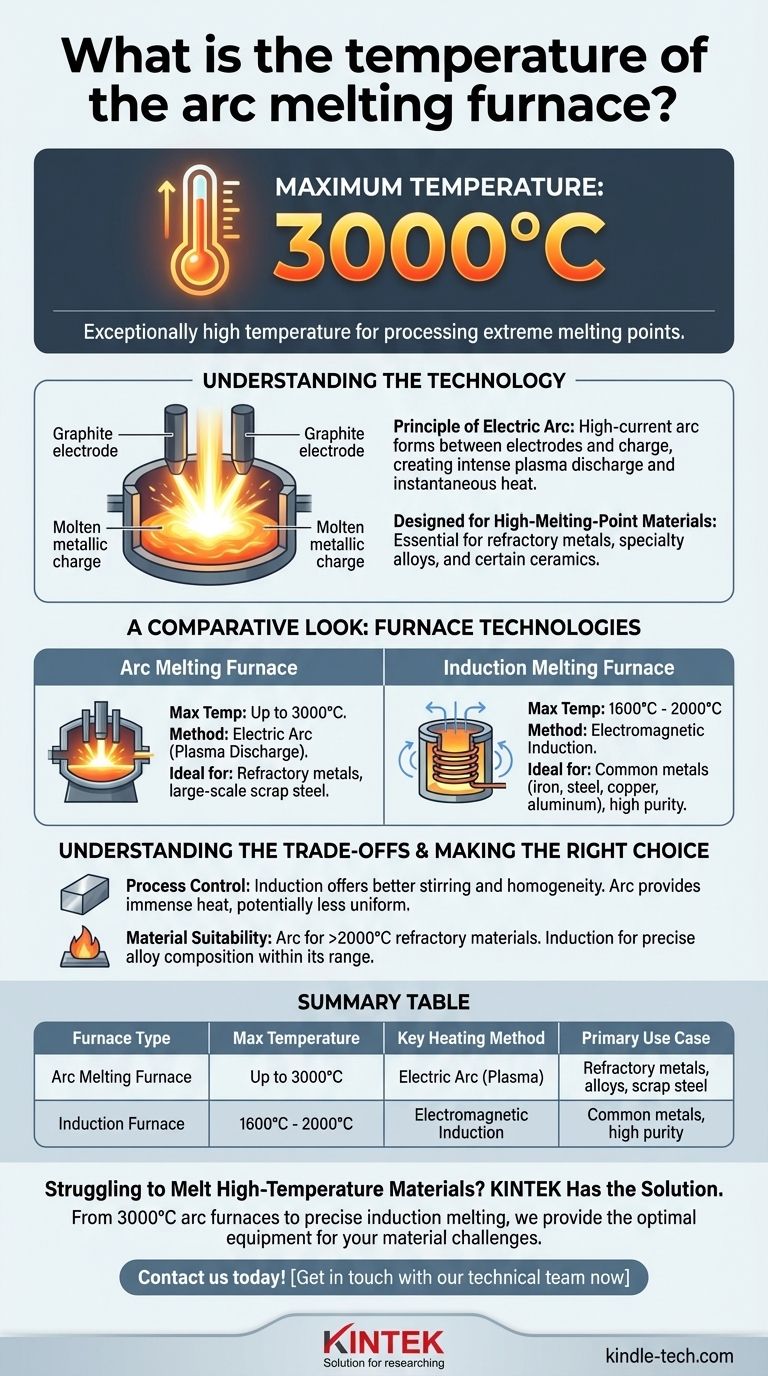

In short, an electric arc melting furnace can achieve an exceptionally high temperature, reaching a maximum of 3000°C. This capability places it in a specialized class of equipment designed for processing materials with extremely high melting points.

The critical takeaway is not just the maximum temperature a furnace can reach, but understanding that different furnace technologies—like arc versus induction—are engineered for fundamentally different material processing needs. The extreme heat of an arc furnace is a specific solution for a unique set of challenges.

Understanding the Technology Behind the Temperature

An arc furnace's ability to reach 3000°C is a direct result of its heating method. It doesn't rely on conventional combustion or resistance heating elements.

The Principle of the Electric Arc

An arc furnace generates heat using a high-current electric arc that forms between graphite electrodes and the metallic charge inside the furnace.

This arc is essentially a continuous, high-energy spark—a plasma discharge that can reach thousands of degrees Celsius almost instantaneously. This intense, focused energy is transferred directly to the material, enabling it to melt substances that other furnaces cannot.

Designed for High-Melting-Point Materials

The primary reason for developing a furnace capable of 3000°C is to process refractory metals and specialty alloys.

Materials like tungsten, tantalum, and certain ceramics have melting points far beyond the capabilities of more common furnace types. The arc furnace is the necessary tool for these demanding industrial and research applications.

A Comparative Look at Furnace Technologies

To put the arc furnace's capability into perspective, it's helpful to compare it with other common electric melting technologies, such as induction furnaces.

Arc Melting Furnace (Up to 3000°C)

This furnace is the top performer for maximum temperature. Its direct plasma heating is ideal for melting scrap steel in large quantities and processing specialty materials with the highest melting points.

Induction Melting Furnace (1600°C - 2000°C)

An induction furnace uses electromagnetic induction to heat the material. While highly efficient and offering excellent metallurgical control, its maximum temperature is typically limited to around 2000°C.

This temperature is more than sufficient for melting most common metals, including iron, steel, copper, and aluminum, but it cannot handle the most demanding refractory materials.

Understanding the Trade-offs

Choosing a furnace is not simply about picking the one with the highest temperature. Each technology comes with a distinct set of operational trade-offs.

Temperature vs. Process Control

While an arc furnace provides immense heat, the energy from the arc can be less uniform, creating "hot spots."

In contrast, an induction furnace offers more precise temperature control and promotes a stirring action in the molten metal, leading to a more homogeneous and consistent final product.

Material Suitability

The choice is often dictated by the material itself. If the melting point of your material exceeds 2000°C, an arc furnace is one of the few viable options.

For materials where purity and precise alloy composition are critical, the controlled environment of an induction furnace is often superior, provided the material's melting point is within its range.

Making the Right Choice for Your Goal

Your application's specific requirements should dictate your choice of furnace technology.

- If your primary focus is melting refractory metals, specialty alloys, or large volumes of scrap steel: The 3000°C capability of an arc melting furnace is essential.

- If your primary focus is melting standard metals like iron, copper, or aluminum with high purity and compositional control: An induction furnace's range of 1600°C to 2000°C offers the ideal balance of heat and precision.

Ultimately, selecting the correct furnace is about matching the right thermal tool to your specific material challenge.

Summary Table:

| Furnace Type | Maximum Temperature | Key Heating Method | Primary Use Case |

|---|---|---|---|

| Arc Melting Furnace | Up to 3000°C | Electric Arc (Plasma Discharge) | Refractory metals, specialty alloys, large-scale scrap steel |

| Induction Furnace | 1600°C - 2000°C | Electromagnetic Induction | Common metals (iron, steel, copper, aluminum) with high purity requirements |

Struggling to Melt High-Temperature Materials? KINTEK Has the Solution.

Whether you're working with refractory metals requiring 3000°C arc furnace capabilities or need precise control for standard alloys, KINTEK specializes in providing the right lab equipment for your specific material challenges. Our experts will help you select the optimal furnace technology to maximize efficiency, purity, and performance.

Contact us today to discuss your application requirements and discover how our specialized melting solutions can advance your research or production goals. Get in touch with our technical team now!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is a muffle furnace used for in a lab? Achieve Clean, High-Temperature Processing

- What is the specific heat capacity for melting? Clarifying Latent Heat vs. Specific Heat

- What is the difference between sintering and firing? A Guide to Thermal Process Terminology

- What is the highest temperature of a furnace? Unlocking the Limits of Extreme Heat

- What are the factors that affect melting? Master Temperature, Pressure & Chemistry for High-Quality Results