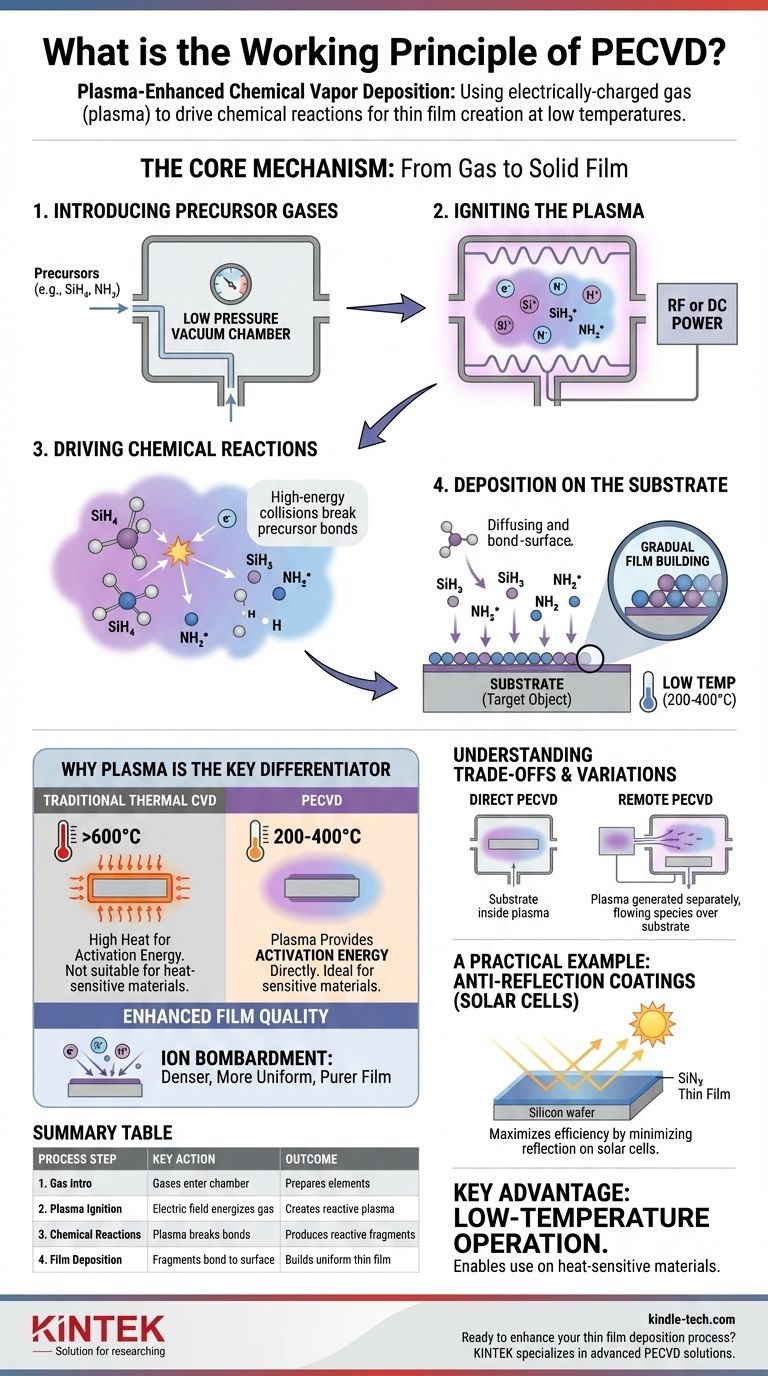

The working principle of PECVD is to use an electrically-charged gas, known as a plasma, to drive the chemical reactions needed to create a thin film on a surface. Unlike traditional Chemical Vapor Deposition (CVD) which relies on high heat, Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses the energy of the plasma to break down precursor gases. This fundamental difference allows the deposition to occur at much lower temperatures, making it suitable for sensitive materials.

The central innovation of PECVD is its use of plasma to supply the energy for chemical reactions, rather than relying on high heat. This decoupling of reaction energy from thermal energy is what makes the process indispensable for manufacturing modern electronics and other temperature-sensitive components.

The Core Mechanism: From Gas to Solid Film

PECVD transforms gaseous chemicals into a solid, high-purity thin film through a precise, four-step process inside a vacuum chamber.

Step 1: Introducing Precursor Gases

The process begins by introducing specific reactive gases, called precursors, into a low-pressure vacuum chamber. These gases contain the elements required for the final film, such as silane (SiH₄) and ammonia (NH₃) to create a silicon nitride film.

Step 2: Igniting the Plasma

An electric field, typically high-frequency (RF) or direct current (DC), is applied across the chamber. This field energizes the gas, stripping electrons from the atoms and creating a plasma—a highly reactive state of matter consisting of ions, electrons, and neutral radicals.

Step 3: Driving Chemical Reactions

The high-energy electrons within the plasma collide with the precursor gas molecules. These collisions are powerful enough to break the chemical bonds of the precursors, creating a mix of highly reactive molecular fragments. This step is the chemical core of the process.

Step 4: Deposition on the Substrate

These reactive fragments then diffuse to the surface of the target object (the substrate). They react with each other and bond to the surface, gradually building the desired thin film, one layer of atoms at a time.

Why Plasma is the Key Differentiator

The "plasma-enhanced" aspect is not a minor detail; it is the feature that defines the process and gives it a critical advantage over other methods.

Energy Without Extreme Heat

In traditional thermal CVD, the substrate must be heated to very high temperatures (often >600°C) to provide the energy needed to break down the precursor gases. In PECVD, the plasma provides this activation energy directly, allowing the substrate to remain at a much lower temperature (typically 200-400°C).

This low-temperature capability is essential for depositing films on materials that cannot withstand high heat, such as integrated circuits with complex, multi-layered structures.

Enhanced Film Quality

The plasma doesn't just initiate reactions; it also influences the quality of the film. The charged ions from the plasma are accelerated towards the substrate, a phenomenon known as ion bombardment. This action helps to create a denser, more uniform, and purer film than might be achieved with low-temperature thermal methods alone.

Understanding the Trade-offs and Variations

While powerful, PECVD is not a universal solution. Understanding its limitations and variations is key to its effective application.

Direct vs. Remote PECVD

In direct PECVD, the substrate is placed directly within the plasma. While efficient, this can sometimes lead to surface damage from ion bombardment.

To mitigate this, a variant called remote PECVD generates the plasma in a separate chamber. The reactive chemical species are then extracted and flowed over the substrate, which remains in a plasma-free environment, protecting it from potential damage.

Process Complexity

Controlling a plasma environment is more complex than simply managing temperature and pressure. The chemistry of the plasma can be intricate, and achieving a perfectly uniform film over a large area requires sophisticated equipment and process control.

Precursor Selection is Critical

The final properties of the deposited film are a direct reflection of the precursor gases used. Choosing the correct precursors is essential for tailoring the film's characteristics, such as its electrical conductivity, optical properties, or hardness.

A Practical Example: Anti-Reflection Coatings

The production of solar cells provides a clear example of PECVD's importance.

The Goal

To maximize a solar cell's efficiency, you must minimize the amount of sunlight that reflects off its surface. This is achieved by applying an anti-reflection coating.

The Process

PECVD is used to deposit a thin film of silicon nitride (SiNx) onto the silicon wafer. The plasma efficiently decomposes the precursor gases (silane and ammonia), allowing a high-quality SiNx film to form at a temperature low enough to not damage the delicate solar cell beneath it.

Making the Right Choice for Your Goal

Selecting a deposition technology depends entirely on the requirements of your substrate and the desired properties of the final film.

- If your primary focus is depositing on temperature-sensitive substrates (like complex electronics or plastics): PECVD is the superior choice because its low-temperature process prevents thermal damage.

- If your primary focus is creating a simple, highly crystalline film on a robust substrate that can tolerate heat: Traditional thermal CVD might be a simpler and more cost-effective option.

- If your primary focus is achieving the highest possible film density and adhesion at low temperatures: PECVD's inherent ion bombardment provides a distinct advantage over other low-temperature methods.

Ultimately, understanding PECVD is about recognizing its unique ability to deliver high-energy chemistry without high-temperature consequences.

Summary Table:

| PECVD Process Step | Key Action | Outcome |

|---|---|---|

| Step 1: Gas Introduction | Precursor gases (e.g., SiH₄, NH₃) enter vacuum chamber | Prepares chemical elements for film formation |

| Step 2: Plasma Ignition | Electric field energizes gas, creating plasma | Generates reactive ions, electrons, and radicals |

| Step 3: Chemical Reactions | Plasma breaks precursor bonds | Produces reactive fragments for deposition |

| Step 4: Film Deposition | Fragments bond to substrate surface | Builds uniform, high-purity thin film layer by layer |

| Key Advantage | Low-Temperature Operation | Enables use on heat-sensitive materials (200-400°C vs. >600°C for thermal CVD) |

Ready to enhance your thin film deposition process? KINTEK specializes in advanced PECVD solutions and lab equipment, delivering precise, low-temperature deposition for sensitive substrates like integrated circuits and solar cells. Contact us today to explore how our expertise can optimize your laboratory's capabilities and accelerate your research or production goals.

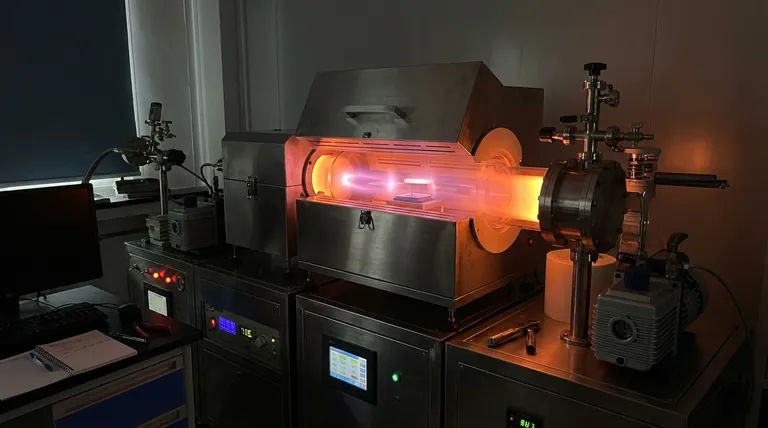

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition