At its core, vacuum brazing is a high-purity joining process. It connects two or more metal components by melting a specialized filler metal between them inside a vacuum chamber. Because the vacuum prevents oxidation, the process creates exceptionally strong, clean, and flux-free joints without contaminating the base materials.

The critical insight is that the vacuum is not just an empty space; it is an active element of the process. It acts as the "flux" by removing air and other contaminants, enabling a metallurgical bond of superior strength and integrity that is often unachievable with other methods.

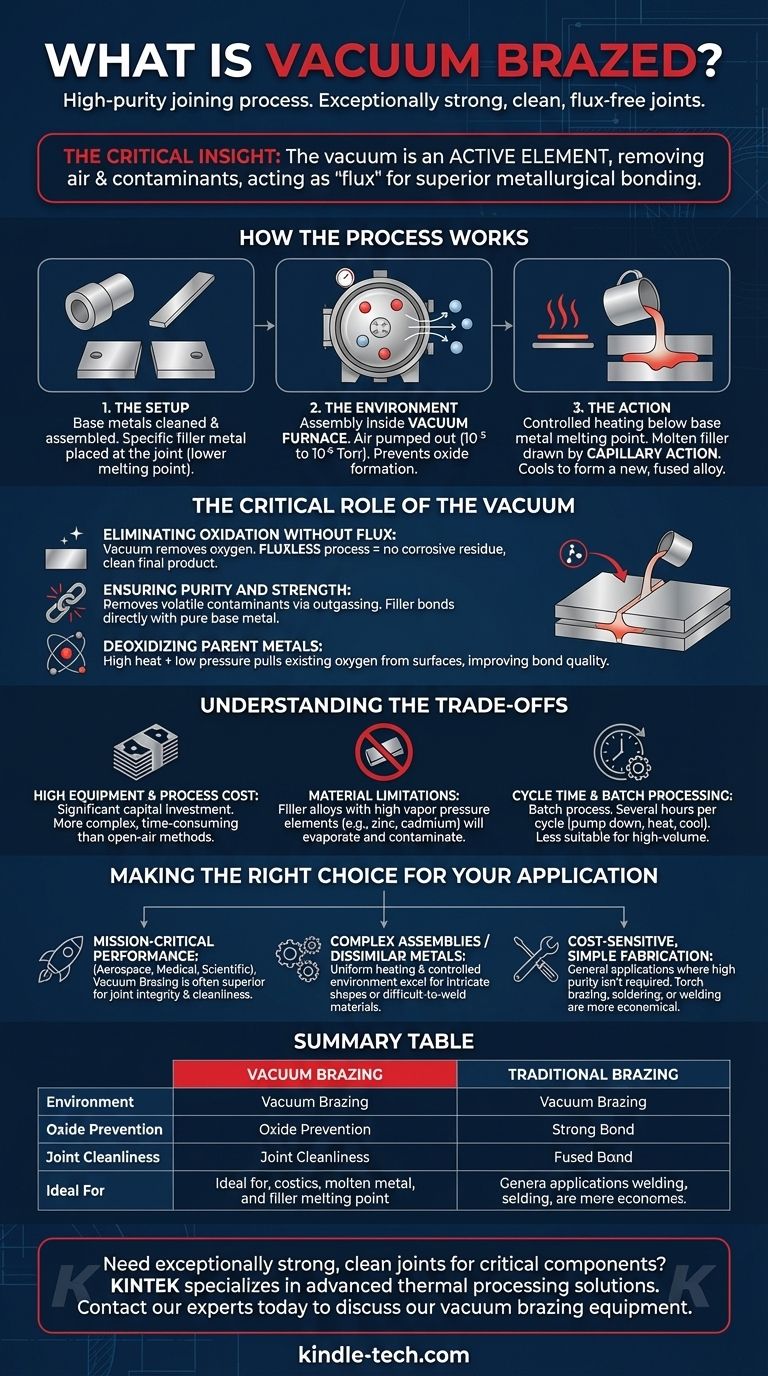

How the Vacuum Brazing Process Works

Vacuum brazing is a precise, multi-stage thermal process conducted inside a specialized furnace. The goal is to create a seamless, permanent bond between components.

The Setup: Base Metals and Filler

First, the components to be joined, known as the base metals, are cleaned and assembled.

A specific filler metal (or brazing alloy) is placed at the joint. This filler is chosen for two key properties: it must have a lower melting point than the base metals, and its chemical makeup must be stable under vacuum.

The Environment: The Vacuum Furnace

The entire assembly is placed inside a vacuum furnace. Air and other gases are pumped out, creating a low-pressure environment, typically in the range of 10⁻⁵ to 10⁻⁶ Torr.

This vacuum is essential for preventing the formation of oxides on the metal surfaces when they are heated.

The Action: Melting, Flow, and Bonding

The furnace heats the assembly in a controlled cycle. The temperature rises above the melting point of the filler metal but stays safely below the melting point of the base metals.

Once molten, the liquid filler metal is drawn into the tight gap between the components through capillary action. It "wets" the surfaces of the base metals, creating a new, fused alloy at the joint as it cools and solidifies.

The Critical Role of the Vacuum

The use of a vacuum is what distinguishes this process and provides its unique advantages. It fundamentally changes how the metals interact at high temperatures.

Eliminating Oxidation Without Flux

In traditional brazing, a chemical flux is required to clean the metal surfaces and prevent oxidation. This flux can be corrosive and must be thoroughly cleaned off after joining.

Vacuum brazing is a fluxless process. The vacuum itself removes the oxygen, making flux unnecessary and resulting in an exceptionally clean final product with no risk of trapped flux contaminants that could cause corrosion later.

Ensuring Purity and Strength

The vacuum also removes other volatile contaminants from the metal surfaces through outgassing. This ensures the filler metal can bond directly with pure base metal, creating the strongest possible metallurgical joint.

Deoxidizing the Parent Metals

Under the right conditions of high heat and low pressure, the vacuum environment can actually pull existing, loosely bonded oxygen atoms off the surface of the metals, a process known as deoxidizing. This further improves the quality of the final bond.

Understanding the Trade-offs

While powerful, vacuum brazing is not the solution for every application. Understanding its limitations is key to making an informed decision.

High Equipment and Process Cost

Vacuum furnaces represent a significant capital investment. The process itself is also more complex and time-consuming than open-air methods, leading to higher operational costs per part.

Material Limitations

The filler metal must be selected carefully. Alloys containing elements with high vapor pressure, such as zinc or cadmium, cannot be used as they would evaporate in the vacuum, contaminating both the furnace and the joint.

Cycle Time and Batch Processing

Vacuum brazing is a batch process, not a continuous one. Each cycle of pumping down the vacuum, heating, and cooling can take several hours, making it less suitable for high-volume, low-cost manufacturing compared to methods like automated welding.

Making the Right Choice for Your Application

Choosing a joining method depends entirely on the requirements of the final product, from its performance specifications to its budget.

- If your primary focus is mission-critical performance: For aerospace, medical, or scientific applications where joint integrity and cleanliness are paramount, vacuum brazing is often the superior or only viable choice.

- If your primary focus is joining complex assemblies or dissimilar metals: The uniform heating and controlled environment of a vacuum furnace excel at creating stress-free joints between intricate shapes or materials that are difficult to weld.

- If your primary focus is cost-sensitive, simple fabrication: For general applications where high purity is not a requirement, other methods like torch brazing, soldering, or welding are typically far more economical.

Ultimately, vacuum brazing is a sophisticated solution for creating joints that are as strong and pure as the parent materials themselves.

Summary Table:

| Feature | Vacuum Brazing | Traditional Brazing |

|---|---|---|

| Environment | High-Vacuum Chamber | Air (with Flux) |

| Oxide Prevention | Vacuum removes oxygen | Chemical flux required |

| Joint Cleanliness | High-purity, flux-free | Risk of flux contamination |

| Ideal For | Mission-critical, complex assemblies | Cost-sensitive, simple fabrication |

Need to create exceptionally strong, clean joints for your critical components? KINTEK specializes in advanced thermal processing solutions, including vacuum brazing systems designed for high-purity applications in aerospace, medical, and scientific industries. Our expertise ensures your lab achieves superior metallurgical bonds without contamination. Contact our experts today to discuss how our vacuum brazing equipment can enhance your manufacturing process.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the effects of sintering on the powder compact produced by pressing? Achieve Strong, Dense Parts

- What role does a vacuum diffusion welding furnace play in the fabrication of multi-layer titanium alloy laminates?

- What are the uses of heat treated aluminum alloys? Unlock High-Strength, Lightweight Performance

- Why must a vacuum system be used for drying magnetic nanopowders? Protect Purity and Magnetic Strength

- What is the pressure in a pyrolysis reactor? A Guide to Optimizing Your Process

- What is the temperature used in hardening? Master the Key to Steel Hardening Success

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- Why is a high-purity argon protection system required in a vacuum arc furnace? Protect Ti-Zr-Hf-V-Ta Alloy Integrity