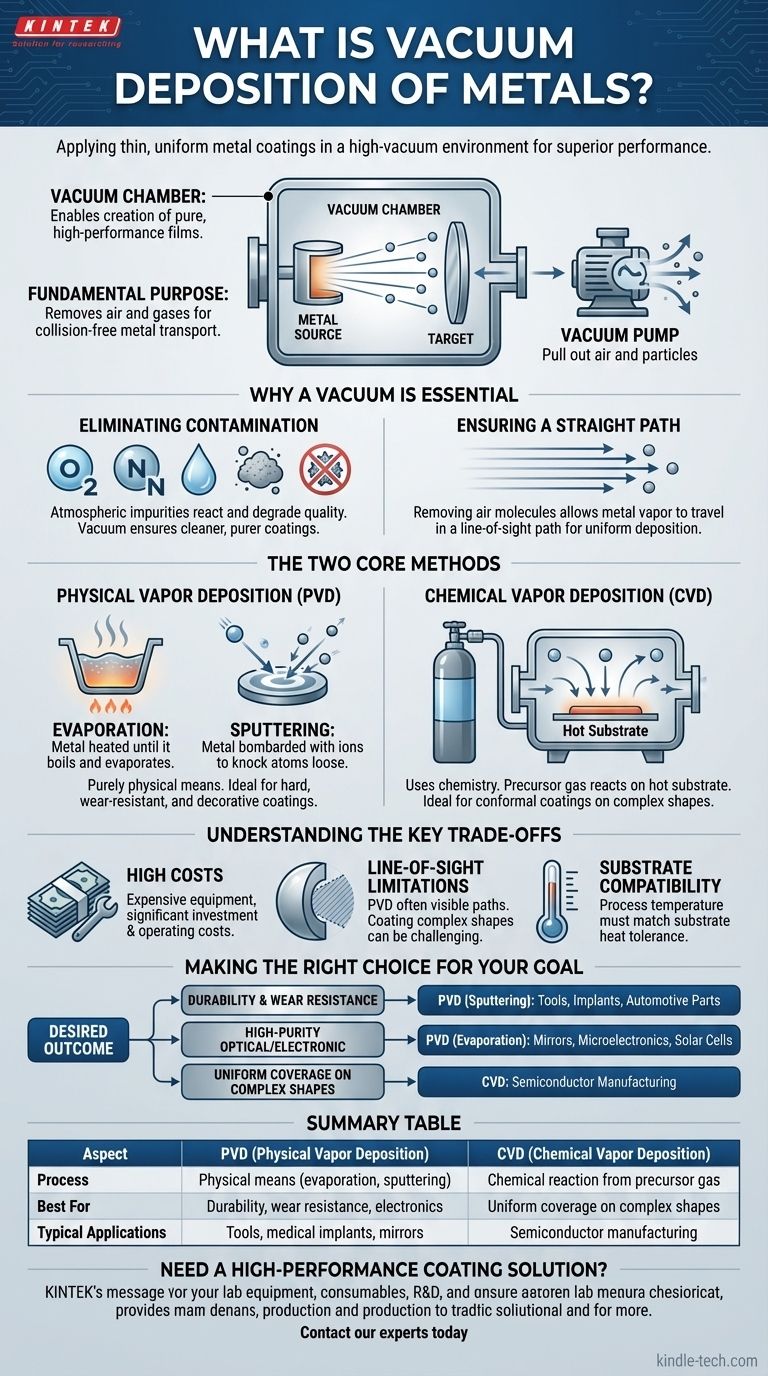

At its core, vacuum deposition of metals is a family of processes used to apply a very thin, highly uniform coating of metal onto a surface. This is all done inside a vacuum chamber, which is the critical element that allows for the creation of extremely pure and high-performance films for applications ranging from microchips to aerospace components.

The fundamental purpose of using a vacuum is to remove air and other gaseous particles. This ensures the metal atoms can travel from their source to the target surface without collisions or contamination, resulting in a cleaner, denser, and more adherent coating.

Why a Vacuum is Essential for Quality Coatings

Operating in a vacuum isn't just a minor detail; it is the central principle that makes this technology so effective. It fundamentally changes the environment to allow for precise, molecular-level construction of a film.

Eliminating Contamination

Atmospheric air contains reactive gases like oxygen and nitrogen, as well as water vapor and dust.

These particles can react with the metal vapor or embed themselves into the growing film, creating impurities that degrade its quality, performance, and adhesion. A vacuum removes these contaminants.

Ensuring a Straight Path for Deposition

By removing most of the air molecules, the chamber becomes an open space.

This allows the vaporized metal atoms to travel in a straight line from the source to the substrate. This "line-of-sight" travel is crucial for creating uniform and predictable coatings.

The Two Core Methods of Vacuum Deposition

While the goal is the same—applying a thin metal film—the methods for getting the metal into a vapor state generally fall into two major categories.

Physical Vapor Deposition (PVD)

PVD processes use purely physical means to turn the solid metal source material into a vapor.

The most common methods are Evaporation, where the metal is heated until it boils and evaporates, and Sputtering, where the metal source is bombarded with high-energy ions, knocking atoms loose. PVD is widely used for creating hard, wear-resistant, and decorative coatings.

Chemical Vapor Deposition (CVD)

CVD takes a different approach by using chemistry.

In this process, a precursor gas containing the desired metal is introduced into the vacuum chamber. The gas decomposes on the hot substrate surface, causing a chemical reaction that deposits the metal film and leaves behind volatile byproducts, which are pumped away.

Understanding the Key Trade-offs

Vacuum deposition is a powerful but demanding technology. Its benefits come with significant technical and financial considerations that dictate its use cases.

High Equipment and Operating Costs

Creating and maintaining a high-vacuum environment requires sophisticated and expensive equipment, including specialized chambers and powerful pumps. This makes the initial investment and operating costs significant.

Line-of-Sight Limitations

Many PVD processes, particularly evaporation and sputtering, are "line-of-sight." This means they can only coat surfaces that are directly visible from the metal source. Coating complex, three-dimensional shapes can be challenging and may require rotating the part during the process.

Substrate and Material Compatibility

The choice of deposition method often depends on the substrate's heat tolerance. Some processes require high temperatures that can damage sensitive materials like plastics, while others can operate at or near room temperature.

Making the Right Choice for Your Goal

The best deposition strategy depends entirely on the desired outcome for the final product.

- If your primary focus is durability and wear resistance: PVD processes like sputtering are ideal for creating hard, dense coatings on tools, medical implants, and automotive parts.

- If your primary focus is high-purity optical or electronic layers: PVD evaporation is excellent for creating highly reflective mirrors or the conductive layers found in microelectronics and solar cells.

- If your primary focus is uniform coverage on complex shapes: CVD is often superior for coating intricate surfaces conformally, a key requirement in semiconductor manufacturing.

Ultimately, vacuum deposition provides an unparalleled level of control for engineering surfaces with specific, enhanced properties.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process | Physical means (evaporation, sputtering) | Chemical reaction from precursor gas |

| Best For | Durability, wear resistance, electronics | Uniform coverage on complex shapes |

| Typical Applications | Tools, medical implants, mirrors | Semiconductor manufacturing |

Need a high-performance coating solution for your project? KINTEK specializes in lab equipment and consumables for vacuum deposition processes, helping you achieve precise, durable, and pure metal films. Whether you're in R&D or production, our expertise ensures you select the right method for your specific application. Contact our experts today to discuss your coating challenges and explore how our solutions can enhance your product's performance and reliability.

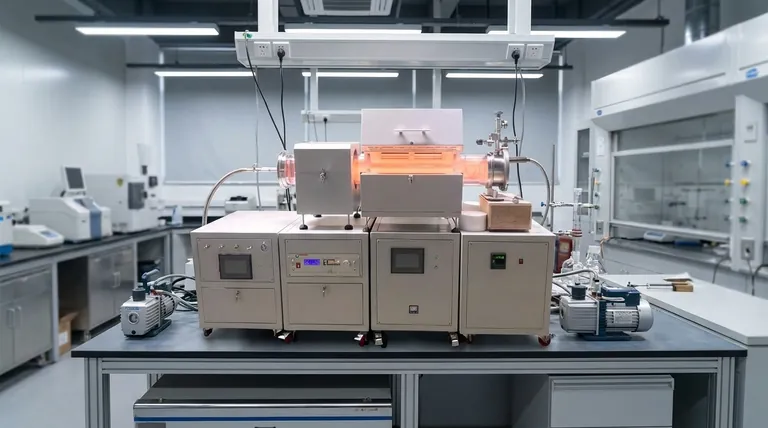

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs