At its core, vacuum hardening is a specialized heat treatment process used to increase the hardness and strength of metals. Unlike traditional methods that heat parts in open air or controlled gas atmospheres, this technique places the components inside a sealed chamber where the air is removed to create a vacuum before heating. This oxygen-free environment is the key to preventing surface reactions like oxidation, resulting in a clean, bright, and dimensionally stable final product.

The true purpose of vacuum hardening extends beyond simply making metal harder. Its primary value lies in achieving superior material properties and a perfect surface finish simultaneously, eliminating the need for costly and time-consuming secondary processing like grinding or chemical cleaning.

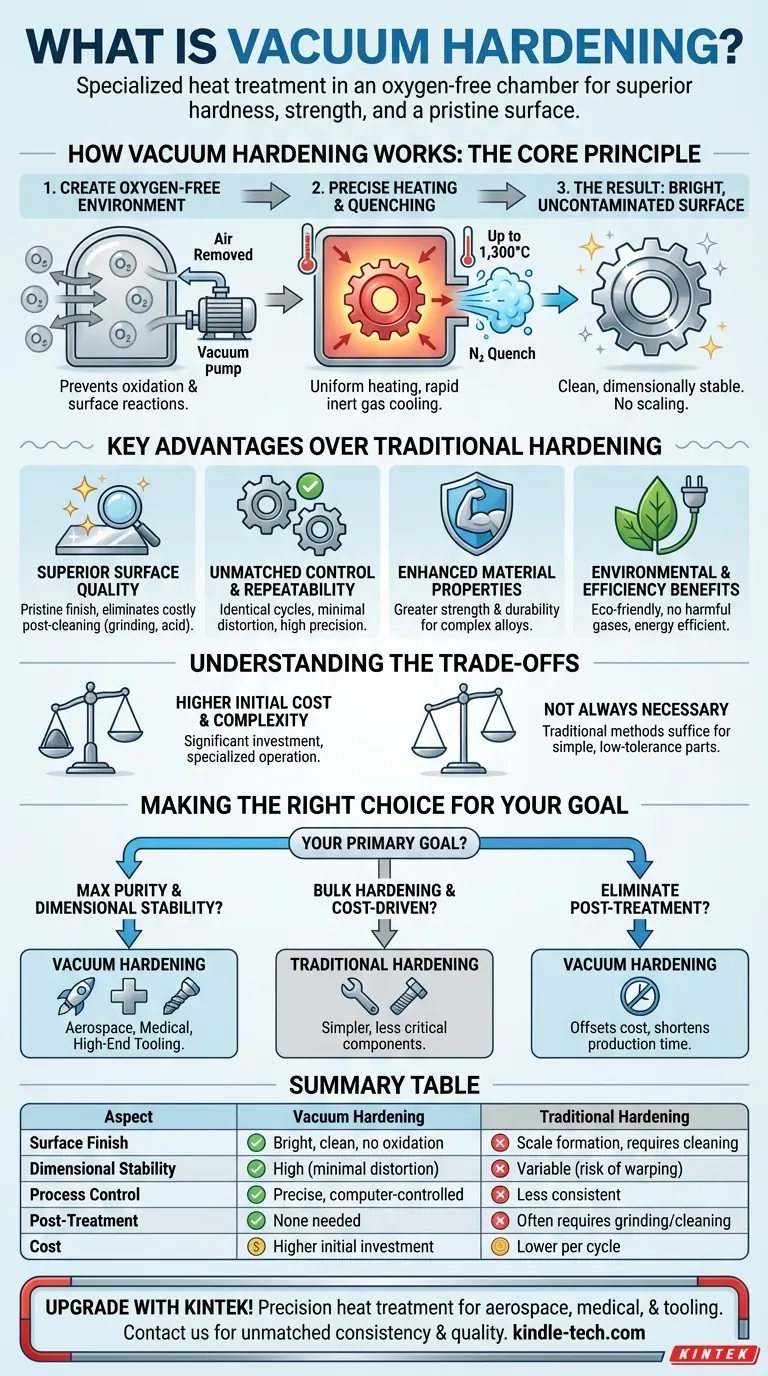

How Vacuum Hardening Works: The Core Principle

The process is defined by its meticulous control over the component's environment during the entire heating and cooling cycle. This precision is what sets it apart from conventional hardening methods.

Creating the Oxygen-Free Environment

Before any heat is applied, a powerful vacuum pumping system removes the air and other gases from a sealed furnace chamber. This step prevents oxygen from reacting with the hot metal surface, which would otherwise form scale or cause discoloration.

Precise Heating and Quenching

Once the vacuum is established, the metal is heated to a specific temperature, which can reach up to 1,300°C. Modern vacuum furnaces use advanced computer controls to ensure the temperature is incredibly stable and uniform. After soaking at this temperature, the component is rapidly cooled (quenched) using an inert gas like nitrogen, locking in the desired hardened microstructure.

The Result: A Bright, Uncontaminated Surface

Because the entire process occurs without oxygen, the metal part emerges from the furnace with a bright, clean, metallic surface. There is no oxidation, and other negative effects like decarburization (loss of carbon from the surface of steel) are completely avoided.

Key Advantages Over Traditional Hardening

Choosing vacuum hardening is a strategic decision to prioritize quality, consistency, and final component integrity. The benefits are significant, especially for high-performance applications.

Superior Surface Quality

The most immediate advantage is the pristine surface finish. This "decorative effect" is actually a sign of high purity, eliminating the need for secondary operations like sandblasting, grinding, or acid cleaning to remove scale.

Unmatched Process Control and Repeatability

Computer-controlled process regulation ensures that every cycle is identical. This high degree of repeatability is critical for industries like aerospace. It also minimizes distortion and warping, ensuring parts maintain their intended dimensions.

Enhanced Material Properties

The process improves the strength and durability of critical components. It is particularly effective for hardening a wide range of metals, including complex tool steels and superalloys that are difficult to treat with conventional methods.

Environmental and Efficiency Benefits

Vacuum hardening is an environmentally friendly process. It avoids the use of potentially harmful gases and, due to the excellent insulation of a vacuum, often consumes less energy than older atmospheric furnace technologies.

Understanding the Trade-offs

While powerful, vacuum hardening is not the solution for every situation. Its advantages come with practical considerations that must be weighed.

Higher Initial Cost

Vacuum furnaces represent a significant capital investment, and the process itself is generally more expensive per cycle than traditional atmospheric hardening. This cost is a primary factor in its application.

Equipment Complexity

The systems required to create and maintain a high vacuum are complex. They demand specialized knowledge for operation and maintenance compared to simpler, conventional furnaces.

Not Always Necessary

For simple, low-tolerance parts where surface finish is not a critical concern, the benefits of vacuum hardening may not justify the additional cost. In these cases, traditional methods are often more than adequate.

Making the Right Choice for Your Goal

Selecting the correct hardening process depends entirely on the requirements of the final component.

- If your primary focus is maximum surface purity and dimensional stability: Vacuum hardening is the definitive choice, especially for complex alloys used in aerospace, medical, or high-end tooling applications.

- If your primary focus is bulk hardening where cost is the main driver: Traditional atmospheric hardening is often a more practical and economical solution for simpler, less critical components.

- If your primary focus is eliminating post-treatment processing: The clean, bright finish from vacuum hardening removes the need for secondary steps, which can offset its higher initial cost and shorten overall production time.

Ultimately, choosing vacuum hardening is an investment in precision, quality, and the final integrity of the component.

Summary Table:

| Aspect | Vacuum Hardening | Traditional Hardening |

|---|---|---|

| Surface Finish | Bright, clean, no oxidation | Scale formation, requires cleaning |

| Dimensional Stability | High (minimal distortion) | Variable (risk of warping) |

| Process Control | Precise, computer-controlled | Less consistent |

| Post-Treatment | None needed | Often requires grinding/cleaning |

| Cost | Higher initial investment | Lower per cycle |

Upgrade your lab's capabilities with precision heat treatment solutions from KINTEK!

Whether you're in aerospace, medical device manufacturing, or tooling, our vacuum hardening equipment ensures superior material properties and flawless surface finishes—eliminating costly secondary processing.

Let our experts help you achieve unmatched consistency and quality for your high-performance components.

Contact KINTEK today to explore how our specialized lab equipment can meet your exact hardening needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the main disadvantage of quenching a part rapidly in water? High Risk of Cracking and Distortion

- Why is a high vacuum furnace used for the homogenization of 3D-printed alloy libraries before corrosion testing? - FAQ

- What is powder sintering? A Guide to Efficient High-Performance Part Manufacturing

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- What is the role of vacuum in deposition methods? Master Purity and Control for Superior Thin Films

- What is the pressure range for pyrolysis? Optimize Product Yields with Precise Control

- What is the function of the heat treatment process? Tailor Material Properties for Your Application

- What do you need to consider to have a good brazing process? A Guide to Strong, Reliable Joints