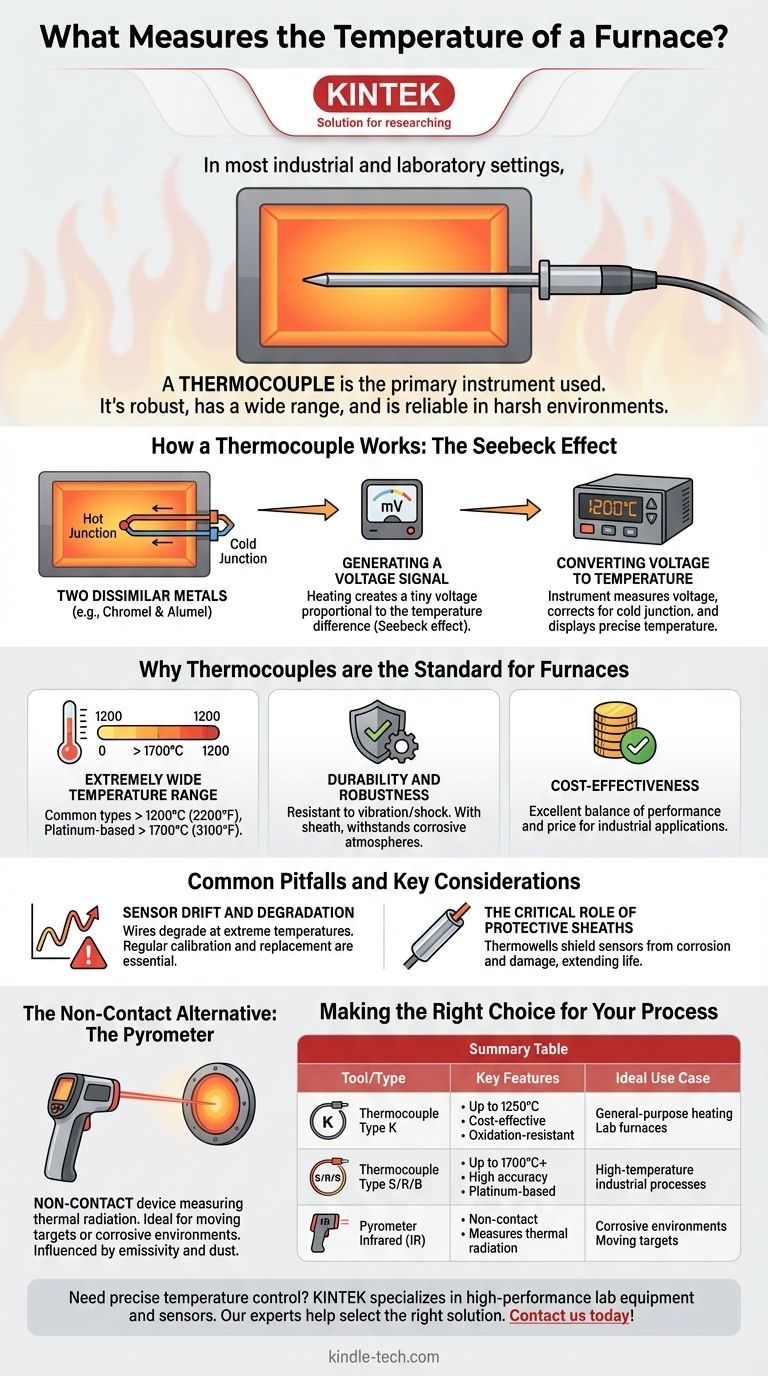

In most industrial and laboratory settings, a thermocouple is the primary instrument used to measure the internal temperature of a furnace. This robust sensor is favored for its ability to withstand extreme heat, its wide measurement range, and its reliability in harsh environments.

The core challenge in furnace temperature measurement isn't just finding a tool that can survive the heat, but choosing one that provides accurate and repeatable data for precise process control. While thermocouples are the industry standard for direct measurement, understanding their types and limitations is critical.

How a Thermocouple Works: The Seebeck Effect

A thermocouple operates on a simple, elegant principle of physics discovered nearly 200 years ago. It doesn't contain complex electronics at the sensing point, which is key to its high-temperature durability.

Two Dissimilar Metals

A thermocouple is made from two different types of metal wires welded together at one end. This welded junction is the point where the temperature is measured—the "hot junction."

Generating a Voltage Signal

When this hot junction is heated, a tiny voltage (millivolts) is produced that is directly proportional to the temperature difference between the hot junction inside the furnace and the "cold junction" outside. This phenomenon is known as the Seebeck effect.

Converting Voltage to Temperature

This millivolt signal travels along the thermocouple wires to a temperature controller or transmitter. This instrument measures the voltage, applies a correction for the cold junction temperature, and converts the reading into a precise temperature display (e.g., in Celsius or Fahrenheit).

Why Thermocouples are the Standard for Furnaces

While other sensors exist, thermocouples have remained the dominant choice for high-temperature applications for several key reasons.

Extremely Wide Temperature Range

Different types of thermocouples can measure a vast spectrum of temperatures. Common types work well above 1200°C (2200°F), while specialized platinum-based types can accurately measure temperatures approaching 1700°C (3100°F) and higher.

Durability and Robustness

Their simple construction—essentially two welded wires—makes them inherently resistant to vibration and mechanical shock. When housed in a protective sheath, they can withstand corrosive and high-pressure furnace atmospheres.

Cost-Effectiveness

Compared to other high-temperature sensors, thermocouples provide an excellent balance of performance and price, making them a practical choice for most industrial applications.

Common Pitfalls and Key Considerations

Simply choosing a thermocouple is not enough. Proper selection and implementation are critical for accuracy and longevity.

Sensor Drift and Degradation

At extreme temperatures, thermocouple wires can degrade, causing the voltage signal to "drift" and give inaccurate readings over time. Regular calibration checks and planned replacement are essential for critical processes.

The Critical Role of Protective Sheaths

The thermocouple is almost always protected by a sheath, typically made of ceramic or a high-temperature metal alloy. This thermowell shields the sensor from chemical corrosion and physical damage inside the furnace, dramatically extending its life.

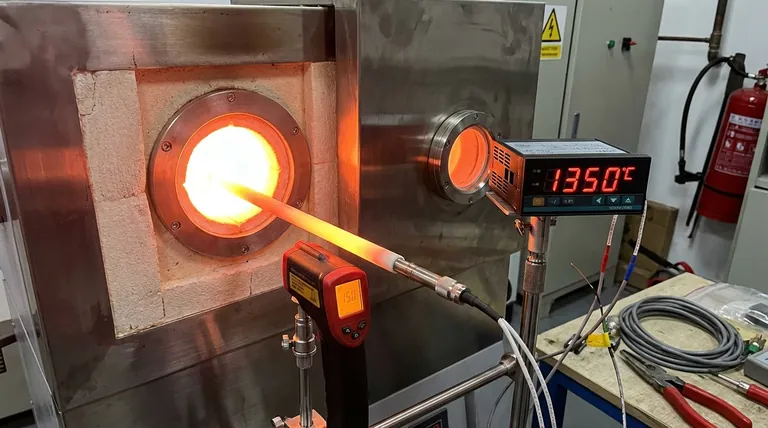

The Non-Contact Alternative: The Pyrometer

In some cases, direct contact measurement is impossible or impractical. An infrared (IR) pyrometer is a non-contact device that measures temperature by detecting the thermal radiation an object emits. It is aimed at the target through a viewport in the furnace wall.

Pyrometers are ideal for measuring moving targets or when the furnace atmosphere would instantly destroy a probe. However, their accuracy can be affected by dust, smoke, and the surface properties (emissivity) of the material being measured.

Making the Right Choice for Your Process

Selecting the correct instrument depends entirely on your specific temperature range, environment, and accuracy requirements.

- If your primary focus is general-purpose heating up to 1250°C (2282°F): A Type K thermocouple offers the best combination of wide range, low cost, and good resistance to oxidation.

- If your primary focus is high-temperature industrial processes above 1250°C (2282°F): A platinum-based Type S, R, or B thermocouple is required for its superior stability and accuracy at extreme temperatures.

- If your primary focus is non-contact measurement due to a corrosive environment or moving product: An infrared pyrometer is the correct tool, but requires careful setup to account for emissivity and atmospheric interference.

Ultimately, precise temperature measurement is the foundation of a controlled and repeatable thermal process.

Summary Table:

| Measurement Tool | Type | Key Features | Ideal Use Case |

|---|---|---|---|

| Thermocouple | Type K | Up to 1250°C, cost-effective, oxidation-resistant | General-purpose heating, lab furnaces |

| Thermocouple | Type S/R/B | Up to 1700°C+, high accuracy, platinum-based | High-temperature industrial processes |

| Pyrometer | Infrared (IR) | Non-contact, measures thermal radiation | Corrosive environments, moving targets |

Need precise temperature control for your furnace processes? KINTEK specializes in high-performance lab equipment and consumables, including durable thermocouples and pyrometers designed for accurate thermal measurement. Our experts can help you select the right sensor for your specific temperature range and environment, ensuring reliable process control and repeatable results. Contact us today to discuss your furnace temperature measurement needs!

Visual Guide

Related Products

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- Infrared Thermal Imaging Temperature Measurement Double-Sided Coated Germanium Ge Lens

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a tube furnace work? Master Precise Thermal and Atmospheric Control

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What are the benefits of a tube furnace? Achieve Superior Temperature & Atmosphere Control

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material