The most critical precautions for using an FTIR spectrometer fall into three main categories: protecting the instrument’s sensitive optics from moisture and contamination, ensuring meticulous sample preparation to achieve accurate data, and adhering to standard chemical safety protocols for the materials you are analyzing.

The central challenge in FTIR operation is not complex theory, but diligent practice. The most common sources of poor results and costly repairs stem from one avoidable issue: contamination of the instrument’s optical components by moisture, atmospheric gases, or the sample itself.

Protecting the Instrument: The Core Priority

The internal components of an FTIR spectrometer are its most valuable and vulnerable parts. The primary goal of any operator is to protect them, particularly from environmental factors.

The Threat of Moisture and CO2

Most FTIR instruments use optical components, like beamsplitters and windows, made from hygroscopic (water-absorbing) materials such as Potassium Bromide (KBr). Exposure to humidity in the air can cause these components to fog or etch permanently, severely degrading performance and requiring expensive replacement.

Furthermore, water vapor and carbon dioxide (CO2) are always present in the atmosphere and absorb infrared radiation strongly. If they are in the instrument's beam path, their signals will interfere with your sample's spectrum, masking important peaks.

The Role of Desiccant

To combat humidity inside the instrument, the optical compartment contains a desiccant, typically silica gel beads. These beads absorb moisture from the enclosed air.

It is crucial to periodically check the desiccant's condition. Many types include an indicator that changes color (e.g., from blue to pink) when saturated and needing replacement or regeneration.

Purging with Dry Gas

For high-performance applications, the instrument should be purged with a dry, inert gas like nitrogen or dry air. This continuous flow of gas displaces the normal atmosphere, effectively removing both water vapor and CO2 from the optical path.

Purging is essential for quantitative analysis or when looking for subtle spectral features that could be obscured by atmospheric interference.

Keep the Sample Compartment Closed

The simplest but most effective precaution is to keep the sample compartment lid closed at all times unless you are actively loading or unloading a sample. This minimizes the exchange of protected internal air with humid lab air.

Ensuring High-Quality Data Through Sample Preparation

An FTIR spectrum is only as good as the sample presented to the instrument. Flaws in preparation are a primary source of inaccurate or non-reproducible data.

Run a Fresh Background Scan

Before analyzing your sample, you must always run a background spectrum. This measurement captures the signal from the instrument and the ambient environment (including any residual H2O and CO2) without the sample present.

The instrument software then subtracts this background from your sample's measurement, isolating the spectrum of your material. This background scan must be performed under the exact same conditions as the sample scan.

Avoid Sample Contamination

Oils from fingerprints, residual solvents, or dust can all absorb IR radiation and will appear in your spectrum. Wear gloves when handling sample holders, ATR crystals, and KBr pellets.

Ensure any solvents used to dissolve a sample or clean a component have fully evaporated before analysis, unless the solvent itself is part of the experiment.

Handle Accessories with Care

FTIR accessories, especially Attenuated Total Reflectance (ATR) crystals, can be fragile and expensive. Be aware of the material of your ATR crystal (e.g., Diamond, Germanium, ZnSe).

Never use hard or sharp objects to apply a solid sample, as this can easily scratch or crack the crystal surface. Clean the crystal thoroughly between samples according to the manufacturer's instructions.

Common Pitfalls to Avoid

Even experienced users can fall into habits that degrade data quality or risk damaging the instrument. Being aware of these common mistakes is a critical precaution.

Pitfall: Neglecting Instrument Warm-up

The infrared source and laser in the spectrometer need time to reach thermal and electronic stability. Turning on the instrument and immediately collecting data can lead to drifting baselines and poor reproducibility. Allow the instrument to warm up for at least 30-60 minutes.

Pitfall: Using an Old Background Scan

It is tempting to use a background scan collected hours or even days earlier. However, environmental conditions in the lab (temperature, humidity) and inside the instrument can change. Always collect a new background if significant time has passed or if conditions have changed.

Pitfall: Overtightening Pressure-Based Accessories

Accessories like ATRs or pellet presses require consistent pressure for good results. However, excessive force can damage the accessory, particularly the ATR crystal. Apply just enough pressure to ensure good contact, and be consistent from sample to sample.

Pitfall: Using Inappropriate Solvents

When cleaning accessories, especially ATR crystals, ensure the solvent you use is chemically compatible with the crystal material and any O-rings or glues in the accessory. Using an incompatible solvent can cause permanent damage.

Making the Right Choice for Your Goal

Your operational focus will dictate which precautions are most critical in the moment.

- If your primary focus is instrument longevity: Make keeping the optical path dry your top priority by regularly checking desiccant and keeping the sample compartment closed.

- If your primary focus is data accuracy: Always run a fresh background scan immediately before your sample and be meticulous about preventing contamination during sample prep.

- If your primary focus is personal and lab safety: Always consult the Safety Data Sheet (SDS) for your samples and solvents before you begin any work.

By integrating these precautions into your routine, you ensure the safety of the operator, the longevity of the instrument, and the integrity of your analytical results.

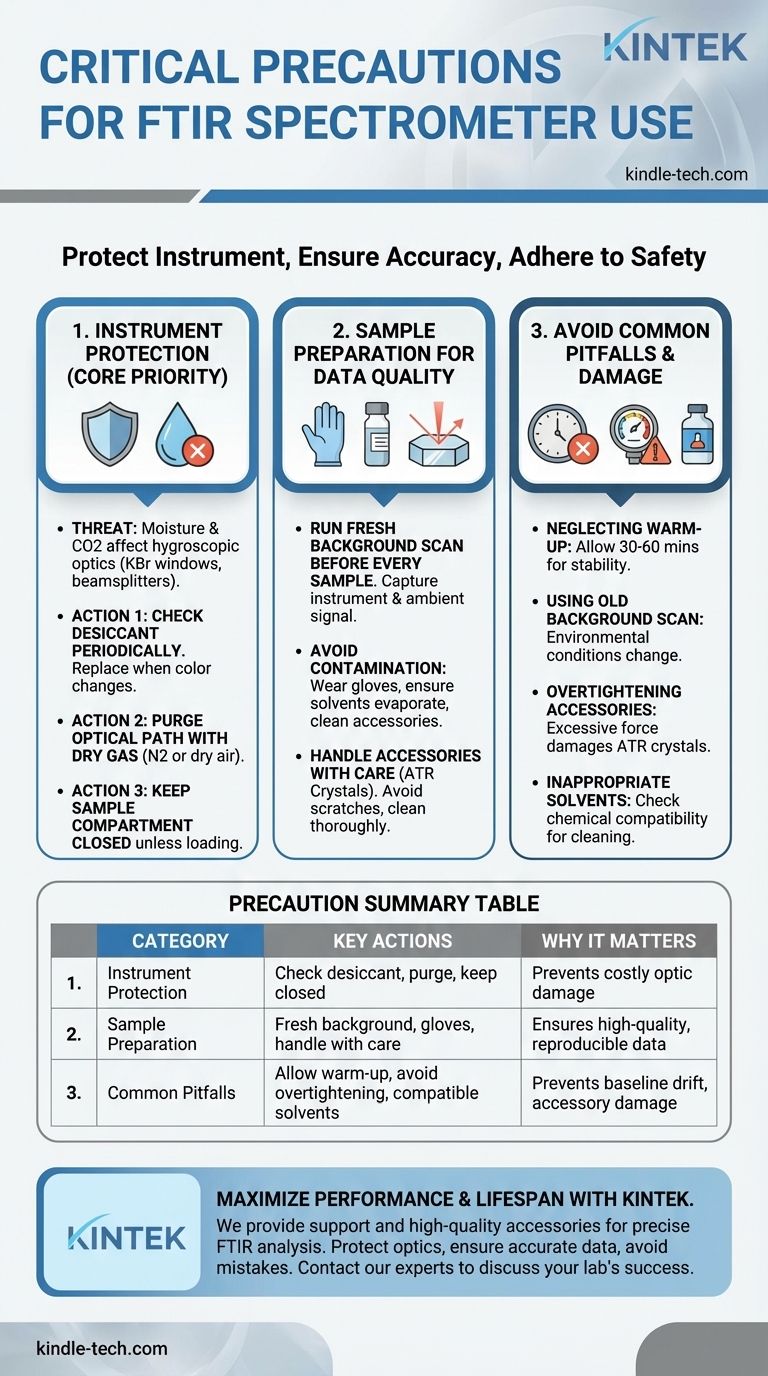

Summary Table:

| Precaution Category | Key Actions | Why It Matters |

|---|---|---|

| Instrument Protection | Check/replace desiccant, purge with dry gas, keep lid closed. | Prevents costly damage to hygroscopic optics from moisture and CO2. |

| Sample Preparation | Run fresh background scans, wear gloves, handle ATR crystals with care. | Ensures high-quality, reproducible data free from contamination. |

| Common Pitfalls | Allow instrument warm-up, avoid overtightening, use compatible solvents. | Prevents baseline drift, accessory damage, and permanent crystal etching. |

Maximize the performance and lifespan of your FTIR spectrometer with KINTEK.

Proper operation is key to protecting your investment and achieving reliable analytical results. KINTEK specializes in laboratory equipment and consumables, providing the support and high-quality accessories you need for precise FTIR analysis.

We help you:

- Protect sensitive optics with the right desiccants and maintenance protocols.

- Ensure accurate data with reliable sample preparation tools and accessories.

- Avoid costly mistakes with expert guidance on best practices.

Ready to enhance your lab's FTIR capabilities? Contact our experts today to discuss your specific needs and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Infrared High Resistance Single Crystal Silicon Lens

- Infrared Thermal Imaging Temperature Measurement Double-Sided Coated Germanium Ge Lens

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- How does thermal treatment equipment enhance biosynthesized ferrihydrite? Unlock High-Performance MRI Contrast Agents

- What types of samples can be analyzed by infrared spectroscopy? Solids, Liquids, Gases & More

- What does sputtering mean in business? A Strategic Manufacturing Process for Competitive Advantage

- What is a cheaper alternative to injection moulding? Find the Right Process for Your Volume

- What is the difference between RF and DC sputtering? Choose the Right Method for Your Material

- How are carbon nanotubes synthesized by laser evaporation? Unlocking High-Purity SWCNTs for Advanced Tech

- What is bio-oil composed of? The Complex Chemistry of a Sustainable Fuel

- What are the important parameters which affect the sputtering process? Master Thin Film Deposition Control