At their most extreme, metal furnaces operate at temperatures between 1400°C and 1800°C (2550°F to 3275°F). However, this range is reserved for high-temperature processes like melting steel. The exact operating temperature depends entirely on the specific metal being worked and the metallurgical goal, with many common applications requiring significantly lower heat.

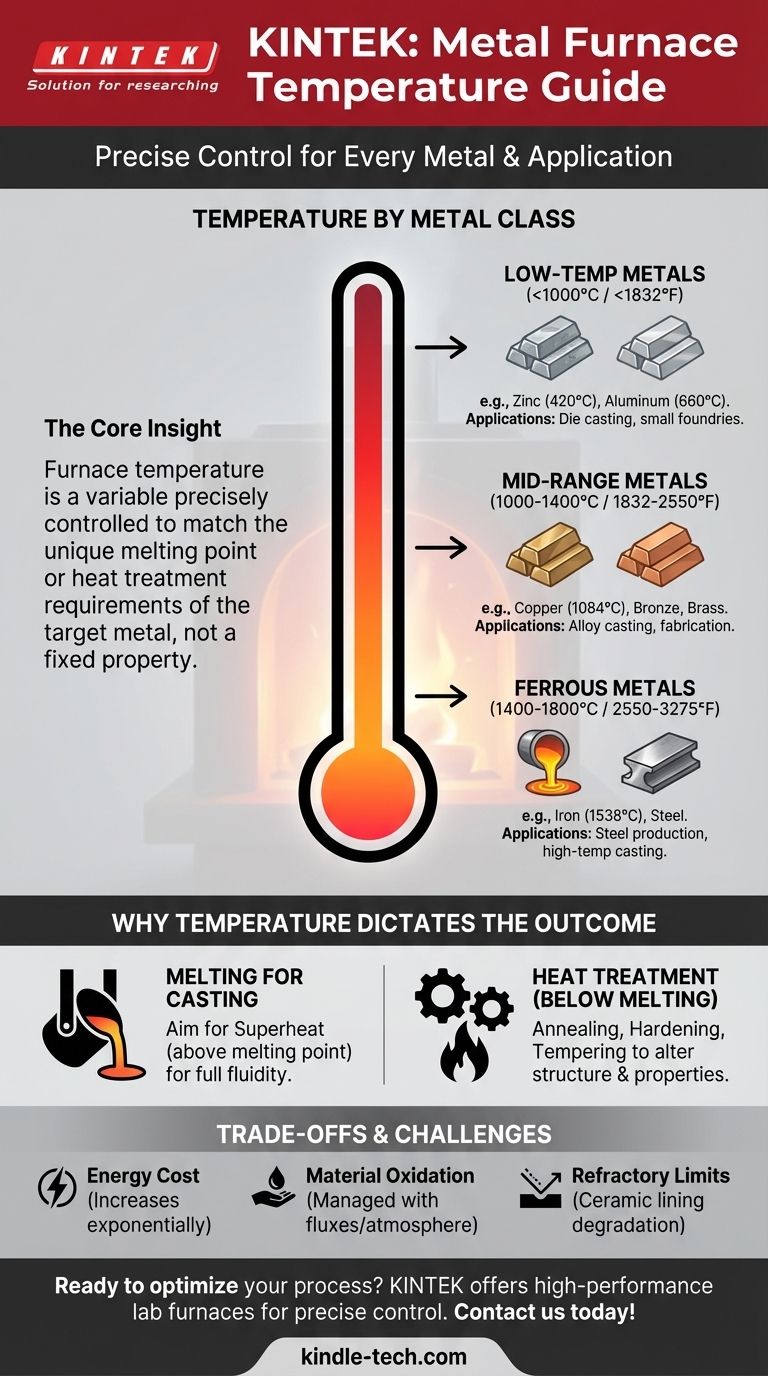

The critical insight is that a furnace's temperature is not a fixed property of the furnace itself, but a variable precisely controlled to match the unique melting point or heat treatment requirements of the target metal.

Why Temperature Dictates the Outcome

In metallurgy, heat is the primary tool for changing a metal's physical state and internal structure. Different temperature ranges unlock entirely different processes and properties, making precise control essential for achieving the desired result.

The Goal: Reaching the Melting Point

The most common reason for heating a metal in a furnace is to melt it for casting. Every pure metal and alloy has a specific melting point that must be exceeded to transition it from a solid to a liquid state.

Furnace operators typically aim for a temperature significantly above the melting point to ensure the metal is fully liquid and fluid enough to pour, a state known as superheat.

The Goal: Changing Structure (Heat Treatment)

Many critical processes occur well below a metal's melting point. This is known as heat treatment.

Processes like annealing (softening), hardening (increasing strength), and tempering (reducing brittleness) rely on heating metal to specific temperatures to rearrange its internal crystal structure, fundamentally altering its mechanical properties without melting it.

Temperature Requirements by Metal Class

Furnaces are chosen based on their ability to reliably reach and hold the temperatures needed for a specific group of metals.

Low-Temperature Metals: Under 1000°C (1832°F)

Metals like zinc (melting point: 420°C) and aluminum (melting point: 660°C) require relatively low energy. Furnaces for these metals, often used in die casting and small-scale foundries, are simpler in construction.

Mid-Range Metals: 1000°C - 1400°C (1832°F - 2550°F)

This range covers common alloys like bronze and brass, as well as pure copper (melting point: 1084°C). These temperatures demand more robust furnace construction and better refractory (heat-resistant) linings.

Ferrous Metals: 1400°C - 1800°C (2550°F - 3275°F)

This is the domain of iron (melting point: 1538°C) and steel. Achieving these temperatures requires specialized high-temperature furnaces, often utilizing electric arc or induction technology. The 1400°C to 1800°C range cited for these furnaces accounts for the high melting point of iron and the need for superheat to cast complex steel alloys.

Understanding the Trade-offs and Challenges

Simply reaching a high temperature is not the only consideration. The process introduces significant technical and financial challenges.

The Cost of Heat

Energy consumption increases exponentially with temperature. Reaching steel-melting temperatures is far more expensive than melting aluminum, impacting everything from operational budget to equipment choice.

Material Oxidation

At high temperatures, most metals react aggressively with oxygen in the air, forming oxides (scale) that represent lost material and can cause defects in a final casting. This is managed by using fluxes, protective slag layers, or controlled-atmosphere furnaces.

Refractory and Equipment Limits

The furnace itself must withstand the heat it contains. The refractory lining, typically a specialized ceramic, has its own temperature limits. Pushing a furnace beyond its designed range will lead to rapid degradation and catastrophic failure.

Making the Right Choice for Your Goal

To select the correct operating temperature, you must first define your material and your objective.

- If your primary focus is casting aluminum or zinc alloys: Your furnace will operate in the 700°C to 850°C range to ensure the metal is fully molten and fluid.

- If your primary focus is melting bronze or copper: You need a furnace capable of reliably holding temperatures between 1100°C and 1250°C.

- If your primary focus is melting steel: You must use a high-temperature furnace that can exceed 1600°C to properly melt the alloy and achieve the necessary fluidity for casting.

- If your primary focus is forging or heat-treating steel: You will work well below its melting point, typically in the 800°C to 1250°C range, depending on the specific treatment.

Mastering temperature control is the foundation of achieving predictable and successful results in any metallurgical work.

Summary Table:

| Metal Type | Typical Operating Range (°C) | Typical Operating Range (°F) | Common Applications |

|---|---|---|---|

| Low-Temp (e.g., Zinc, Aluminum) | < 1000°C | < 1832°F | Die casting, small foundries |

| Mid-Range (e.g., Bronze, Copper) | 1000°C - 1400°C | 1832°F - 2550°F | Alloy casting, fabrication |

| Ferrous (e.g., Iron, Steel) | 1400°C - 1800°C | 2550°F - 3275°F | Steel production, high-temp casting |

Ready to optimize your metalworking process? KINTEK specializes in high-performance lab furnaces and equipment designed for precise temperature control, whether you're melting aluminum or heat-treating steel. Our solutions help you achieve superior results with energy efficiency and durability. Contact us today to discuss your specific needs and let our experts guide you to the right furnace for your application!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the temperature range for brazing? Master the Critical Heat for Strong Joints

- What is the role of catalyst in plastic pyrolysis? Boost Oil Yield & Lower Costs

- What is the normal temperature for a furnace? Unlock the Key to Efficient Home Heating

- What are the steps of the annealing process? Master the 3 Stages to Optimize Material Properties

- What is the temperature and time for quenching? Mastering the Critical Parameters for Hardening Metals

- What is the temperature range for sintering? A Guide to the 0.6-0.8 Tm Rule for Stronger Materials

- Which is better low pressure casting or vacuum permanent mold casting? Choosing the Right Process for Your Component

- Does sintering increase density? Master the Thermal Process for Superior Material Performance