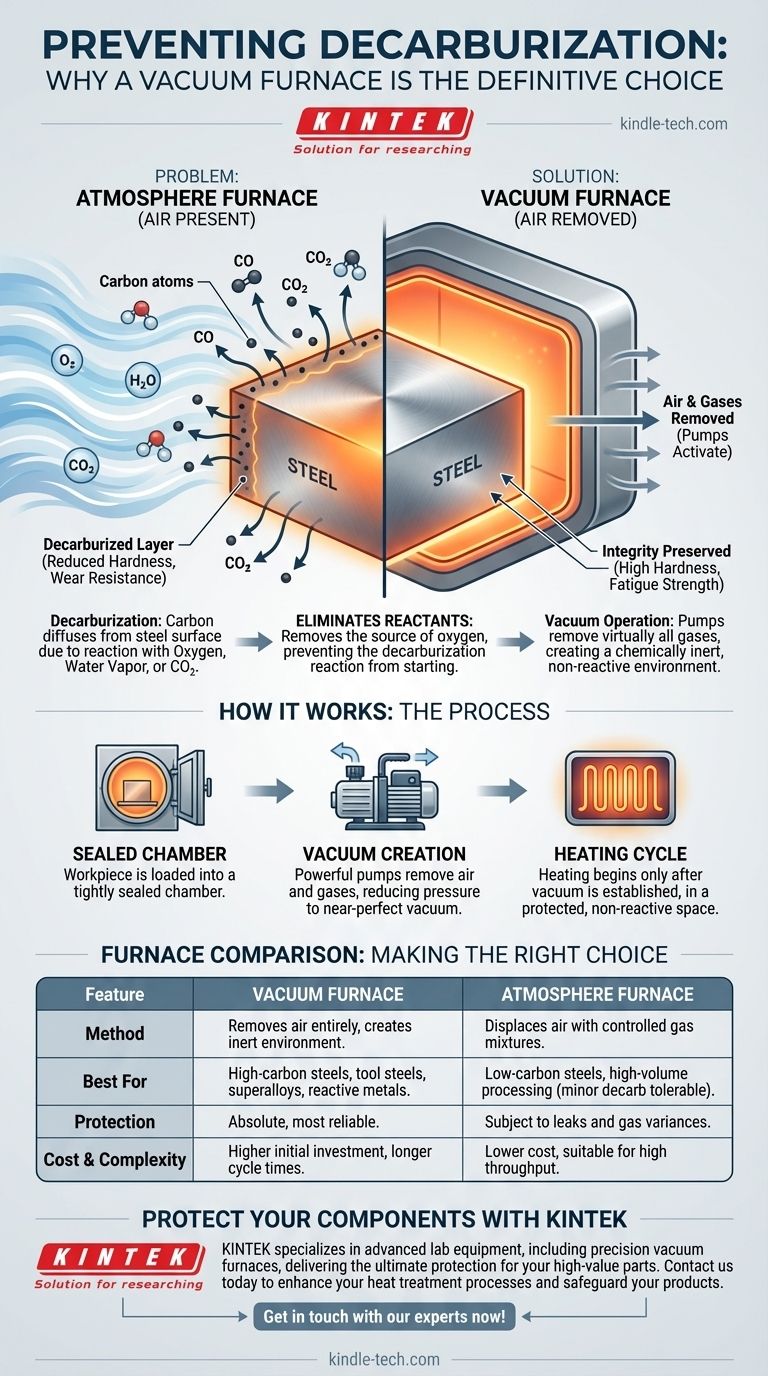

To most effectively prevent decarburization by removing air, a vacuum furnace is the definitive choice. This equipment operates by pumping nearly all gases out of a sealed chamber before the heating cycle begins. By creating a high-vacuum environment, it physically removes the oxygen and other reactive agents that cause carbon loss from the surface of steel, ensuring the material's metallurgical integrity is preserved.

The core challenge in preventing decarburization is controlling the furnace atmosphere. While other methods attempt to displace air with controlled gases, a vacuum furnace solves the problem by removing the atmosphere altogether, offering the most direct and reliable protection against surface carbon loss.

The Mechanism of Decarburization

What is Decarburization?

Decarburization is the process where carbon atoms diffuse from the surface of steel during heat treatment. This loss of carbon depletes the surface layer, significantly reducing its hardness, wear resistance, and fatigue strength.

For components that rely on a hard surface, such as gears, bearings, or tools, decarburization is a critical defect that can lead to premature failure.

The Role of a Reactive Atmosphere

This carbon loss is a chemical reaction that occurs at high temperatures. The carbon within the steel has a high affinity for oxygen.

When heated in the presence of air (which contains oxygen, O₂), water vapor (H₂O), or carbon dioxide (CO₂), the carbon at the surface reacts to form carbon monoxide (CO) or carbon dioxide (CO₂) gas. This reaction effectively pulls carbon atoms right out of the steel.

Why "Removing Air" is the Solution

To stop this reaction, you must eliminate one of the reactants. Since the carbon is integral to the steel, the only variable you can control is the atmosphere.

By removing the air, you remove the source of oxygen, thereby preventing the chemical reaction that causes decarburization from ever starting.

How a Vacuum Furnace Prevents Carbon Loss

The Principle of Vacuum Operation

A vacuum furnace is a tightly sealed chamber connected to a series of powerful pumps. Before heating, these pumps activate to remove the air and any other residual gases, reducing the internal pressure to a near-perfect vacuum.

Only after this vacuum is established does the heating element engage and bring the workpiece up to temperature.

Creating a Non-Reactive Environment

The vacuum creates an environment that is chemically inert, or non-reactive. With virtually no oxygen molecules present, there is nothing for the surface carbon to react with, even at extreme temperatures.

The workpiece is heated and cooled in this protected space, completely isolating it from the risk of decarburization and oxidation.

Superiority in Critical Applications

While traditional atmosphere furnaces displace air with a controlled gas mixture, they are subject to leaks and gas composition variances. A vacuum furnace offers a more absolute level of control.

For sensitive high-carbon steels, tool steels, and superalloys, the clean, non-reactive environment of a vacuum furnace provides a level of quality and consistency that is difficult to achieve otherwise.

Understanding the Trade-offs

Initial Cost and Complexity

Vacuum furnaces represent a significant capital investment. The sealed chamber, robust pumping systems, and sophisticated controls make them more expensive to purchase and maintain than conventional atmosphere furnaces.

Process Cycle Times

The time required to pump the chamber down to the target vacuum level can extend the total process cycle. For high-volume, low-margin parts, this can impact throughput compared to a continuous atmosphere furnace.

When It Might Be Overkill

For low-carbon steels or applications where a small amount of surface decarburization is acceptable or can be removed by post-process machining, a well-managed atmosphere furnace can be a perfectly suitable and more economical choice.

Making the Right Choice for Your Application

Selecting the right furnace technology comes down to the material requirements, the component's end-use, and your operational budget.

- If your primary focus is achieving maximum surface hardness and fatigue life on high-carbon or tool steels: A vacuum furnace is the most reliable choice to prevent any degree of decarburization.

- If your primary focus is high-volume processing of less-sensitive steels where minor surface changes are tolerable: A well-maintained atmosphere furnace often provides a more cost-effective solution.

- If your primary focus is processing highly reactive metals like titanium or specialty alloys: A vacuum furnace is the industry standard and is functionally non-negotiable for preventing contamination.

By understanding the fundamental cause of decarburization, you can confidently choose the technology that best protects the integrity of your components.

Summary Table:

| Furnace Type | Decarburization Prevention Method | Best For |

|---|---|---|

| Vacuum Furnace | Removes air entirely, creating an inert environment | High-carbon steels, tool steels, superalloys, reactive metals |

| Atmosphere Furnace | Displaces air with controlled gas mixtures | Low-carbon steels, high-volume processing where minor decarb is acceptable |

Protect your high-value components from decarburization with KINTEK's precision vacuum furnaces.

Decarburization can compromise the hardness, wear resistance, and fatigue strength of your critical parts, leading to premature failure. KINTEK specializes in advanced lab equipment, including vacuum furnaces that provide the ultimate protection by removing air and creating a perfectly inert environment. This ensures the metallurgical integrity of your high-carbon steels, tool steels, and superalloys is preserved.

Whether you're in aerospace, automotive, or tool manufacturing, our solutions are designed to deliver consistent, high-quality results. Contact us today to discuss how a KINTEK vacuum furnace can enhance your heat treatment processes and safeguard your products. Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the application of vacuum technology in industries? Enabling Precision Manufacturing and Purity

- Where is sinter used? A Guide to Its Critical Role in Manufacturing

- How do you measure a leak? From Simple Drips to Critical Gas Leaks

- What are the three most important factors in material heat treatment? Master Temperature, Time, and Cooling for Superior Properties

- What are the technical consequences of failing to maintain distinct boundaries in a furnace? Master Process Control

- What are the byproducts of plastic pyrolysis? Turning Waste into Valuable Resources

- How does a vertical cylindrical furnace facilitate the titanium electrolysis process? Precision Heat & Shielding

- What is the main advantage of a vacuum oven? Gentle Drying for Heat-Sensitive Materials