The best metal for a heating element is not a single material, but rather a family of specialized alloys chosen based on their specific operating temperature, environment, and cost. For most common applications like toasters or space heaters, nickel-chromium alloys (Nichrome) are the standard. However, for high-temperature industrial furnaces, iron-chromium-aluminum alloys (Kanthal) are superior, and for extreme, chemically-sensitive environments, precious metals like platinum are required.

The search for the "best" heating element is a strategic trade-off. The ideal material must balance high electrical resistivity (to generate heat efficiently) with strong resistance to oxidation at its operating temperature, all within a specific cost profile.

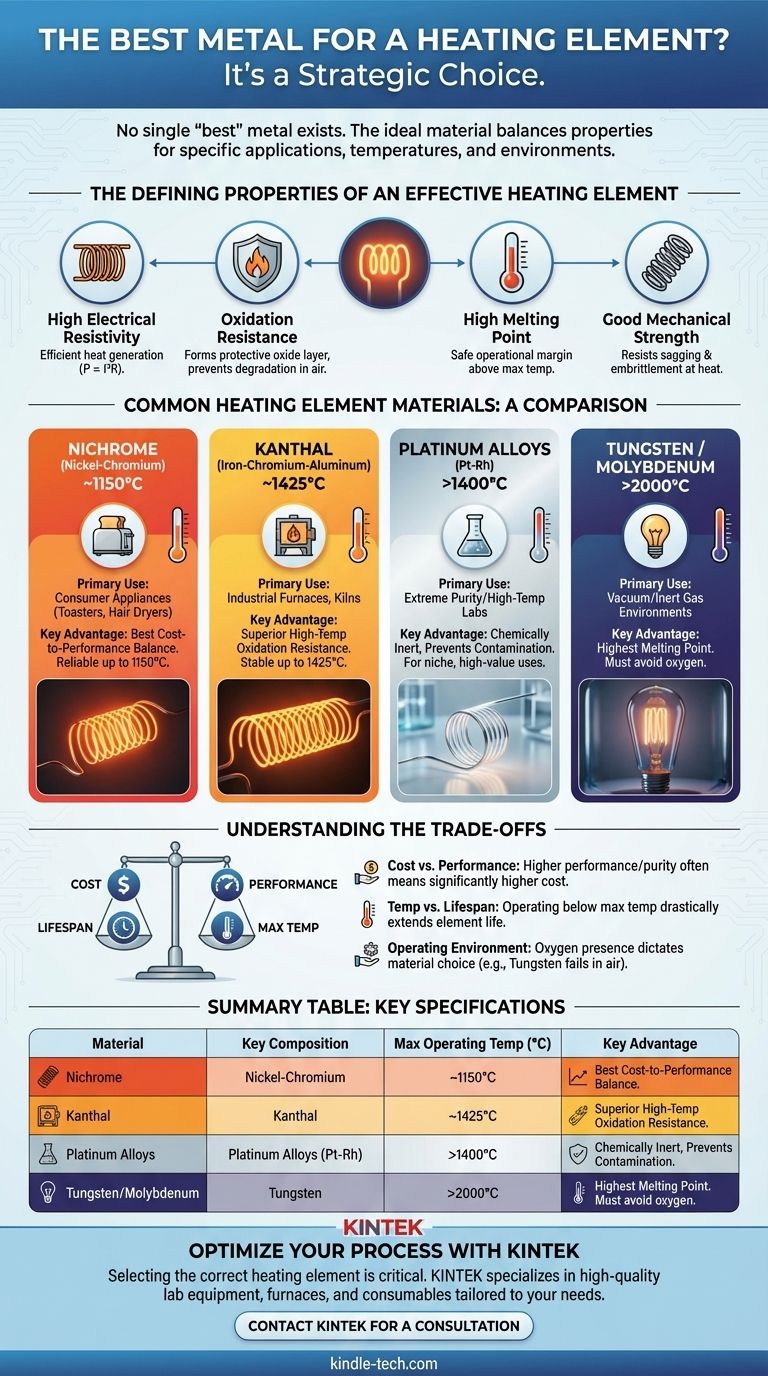

The Defining Properties of an Effective Heating Element

To select the right material, you must first understand the fundamental principles that govern resistive heating. A material's suitability is not based on a single metric, but on the interplay of four key properties.

High Electrical Resistivity

A heating element works by converting electrical energy into heat, a phenomenon known as Joule heating. The formula for power (heat) is P = I²R.

For a given current (I), a higher resistance (R) produces more heat. Materials with high resistivity allow for the creation of robust, appropriately sized heating elements without requiring excessively long wires.

High-Temperature Oxidation Resistance

This is arguably the most critical property. When a metal gets hot in the presence of air, it oxidizes (like rust on iron). A poor heating element would quickly degrade and fail.

Effective heating alloys, like Nichrome and Kanthal, are designed to form a thin, stable, and adherent layer of oxide on their surface (chromium oxide for Nichrome, aluminum oxide for Kanthal). This layer protects the underlying metal from further oxidation, dramatically increasing its lifespan.

High Melting Point

This is a straightforward requirement. The material's melting point must be significantly higher than its maximum operating temperature to provide a safe operational margin and prevent physical failure.

Good Mechanical Strength at Temperature

Materials behave differently when hot. A good heating element must resist sagging, stretching, or becoming brittle at its operating temperature. It needs to maintain its form, whether coiled in a furnace or stretched in a toaster, for thousands of hours.

Common Heating Element Materials: A Comparison

Engineers turn to a small group of specialized alloys, each optimized for a different set of conditions.

Nichrome (Nickel-Chromium): The Workhorse

Nichrome is the most common heating element material. It offers a superb balance of high resistivity, good oxidation resistance, and reasonable cost.

It forms a protective chromium-oxide layer and is the go-to choice for consumer appliances like hair dryers, toasters, and heat guns. Its typical maximum operating temperature is around 1150°C (2100°F).

Kanthal (Iron-Chromium-Aluminum): The High-Temperature Standard

For applications requiring higher temperatures, Kanthal alloys are superior to Nichrome. The addition of aluminum allows it to form an aluminum-oxide layer.

This protective layer is more robust at higher temperatures than the chromium-oxide layer on Nichrome, allowing Kanthal to operate up to 1425°C (2600°F). This makes it standard for electric kilns and industrial furnaces.

Platinum and Rhodium Alloys: The Extreme Environment Specialists

As noted in specialized applications, precious metals are used when performance cannot be compromised. Platinum and its alloys with rhodium offer exceptional resistance to oxidation at very high temperatures.

They are also chemically inert, making them essential for applications like glass manufacturing or laboratory research where contamination from the heating element is unacceptable. Their extremely high cost reserves them for these niche, high-value uses.

Tungsten and Molybdenum: The Vacuum Specialists

Tungsten has the highest melting point of any metal, making it ideal for extremely hot applications like incandescent light bulb filaments. However, both Tungsten and Molybdenum oxidize catastrophically in open air.

They can only be used as heating elements inside a vacuum or a protective, inert gas atmosphere. This limits their use to highly controlled industrial processes and scientific instruments.

Understanding the Trade-offs

Choosing a material is an engineering decision based on balancing competing priorities. There is no universally "best" option, only the most appropriate one for the task.

Cost vs. Performance

This is the primary trade-off. A Nichrome coil may cost a few dollars, while an equivalent platinum coil could cost hundreds or thousands. The expense of a Kanthal furnace element is justified by its long life at high temperatures, whereas the cost of a platinum element is only justified by extreme purity or temperature requirements.

Maximum Temperature vs. Lifespan

Every heating element has a maximum recommended operating temperature. However, running an element continuously at this limit will drastically shorten its lifespan.

Operating an element even 50-100°C below its absolute maximum can multiply its operational life several times over. This is a critical consideration in designing reliable and low-maintenance industrial equipment.

Operating Environment

The presence of oxygen is the deciding factor for many materials. The excellent temperature properties of tungsten are irrelevant for an open-air furnace because it would burn out in seconds. The choice between Nichrome, Kanthal, and Platinum is largely a decision about how hot the element will get in the presence of air.

Making the Right Choice for Your Application

Your choice should be dictated by your primary operational goal and budget.

- If your primary focus is everyday consumer appliances or light industrial use: Nichrome (nickel-chromium) provides the best balance of cost, performance, and reliability.

- If your primary focus is high-temperature industrial furnaces (kilns, heat treating): Kanthal (FeCrAl) alloys are the standard choice for their superior lifespan and stability above 1200°C.

- If your primary focus is extreme temperatures or a chemically pure environment: Platinum-rhodium alloys are necessary despite their high cost to prevent contamination and withstand the harshest conditions.

- If you are operating in a vacuum or inert gas atmosphere: Molybdenum and tungsten become viable, cost-effective options for achieving exceptionally high temperatures.

By matching the material's properties to your specific operational needs, you ensure both efficiency and reliability in your design.

Summary Table:

| Material | Key Composition | Max Operating Temp (°C) | Primary Use Case | Key Advantage |

|---|---|---|---|---|

| Nichrome | Nickel-Chromium | ~1150°C | Consumer Appliances (Toasters, Heat Guns) | Best cost-to-performance balance |

| Kanthal (FeCrAl) | Iron-Chromium-Aluminum | ~1425°C | Industrial Furnaces, Kilns | Superior high-temperature oxidation resistance |

| Platinum Alloys | Platinum-Rhodium | >1400°C | Extreme Purity/High-Temp Labs | Chemically inert, prevents contamination |

| Tungsten/Molybdenum | Pure Metal | >2000°C | Vacuum/Inert Gas Environments | Highest melting point |

Optimize your laboratory or industrial heating process with the right equipment. Selecting the correct heating element is critical for the efficiency, purity, and longevity of your application. KINTEK specializes in providing high-quality lab equipment and consumables, including furnaces and ovens built with the optimal heating elements for your specific needs—whether you require the standard reliability of Kanthal or the extreme purity of platinum systems.

Our experts can help you navigate the trade-offs between temperature, environment, and cost to ensure your project's success. Contact KINTEL today for a consultation and let us provide a solution that ensures reliability and performance for your laboratory.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What material is used for making heating element? Choose the Right Alloy for Your Application