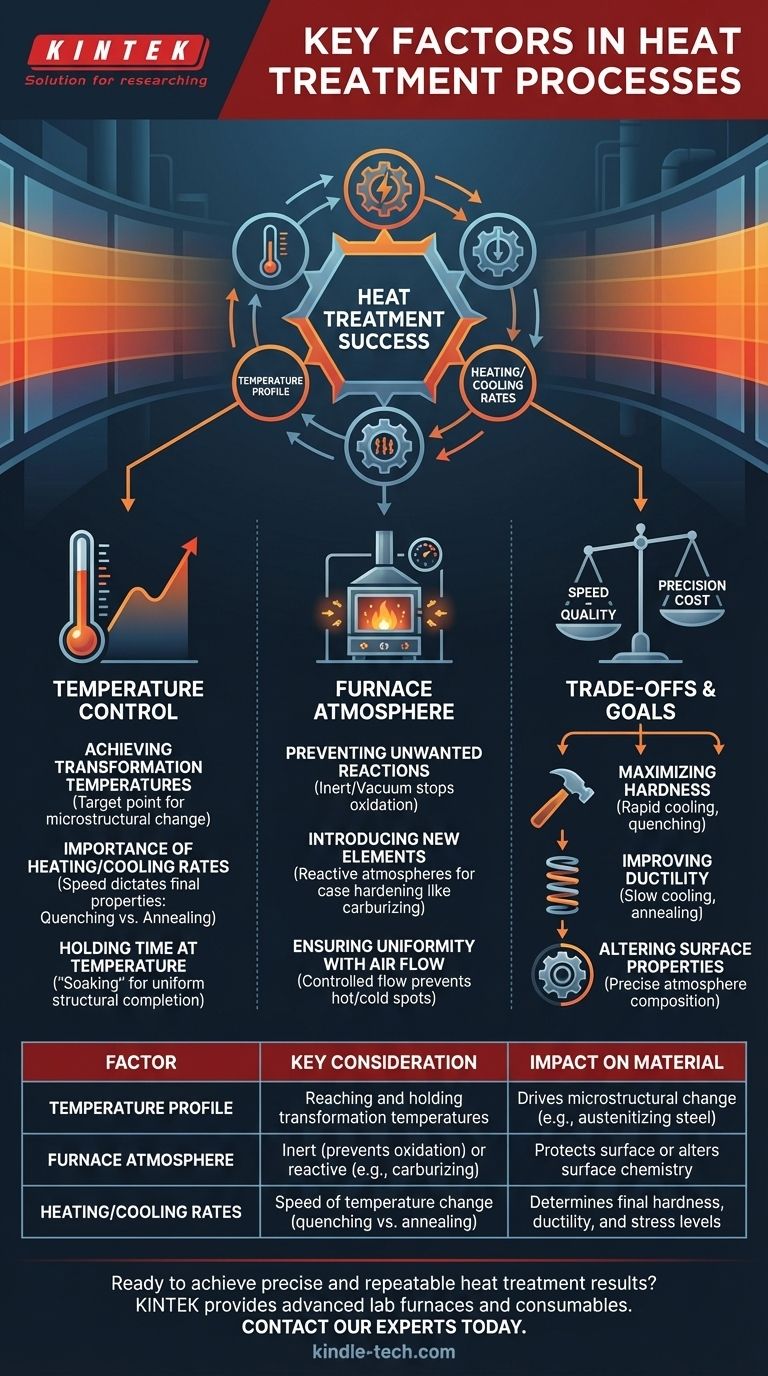

In any heat treatment process, the most critical factors to consider are the temperature profile, the furnace atmosphere, and the rates of heating and cooling. These elements are not independent variables; they work together to fundamentally alter a material’s physical and chemical properties in a controlled and repeatable manner.

The core principle of heat treatment is not simply heating a material, but rather subjecting it to a precisely controlled thermal and atmospheric cycle. Success depends entirely on managing temperature, time, and atmosphere to manipulate the material's internal microstructure and achieve a specific, desired outcome.

The Central Role of Temperature Control

Temperature is the primary driver of change in a material's structure. Without precise control over the entire thermal cycle, the process becomes unreliable and the final quality is compromised.

Achieving Transformation Temperatures

Every heat treatment process has a target temperature. This is the point at which the material's crystal structure (e.g., steel transforming to austenite) becomes receptive to change.

Reaching this temperature uniformly throughout the part is the first and most critical step.

The Importance of Heating and Cooling Rates

The speed at which a material is heated and, more importantly, cooled dictates its final properties. A rapid cool-down (quenching) can trap a hard, brittle structure, while a slow cool-down (annealing) allows for a softer, more ductile one.

These rates must be carefully controlled to prevent thermal shock, distortion, or cracking while achieving the target metallurgy.

Holding Time at Temperature

Once the material reaches its transformation temperature, it must be held there for a specific duration, often called "soaking." This holding time ensures the structural change is complete and uniform from the surface to the core of the component.

The Furnace Atmosphere: A Reactive Environment

The gas or mixture of gases surrounding the material inside the furnace is not merely a background detail; it is an active component of the process.

Preventing Unwanted Reactions

For many processes, the goal is to prevent the material from reacting with its environment. An inert or vacuum atmosphere is used to stop oxidation and scaling, which would otherwise damage the part's surface.

Introducing New Elements

In processes like carburizing or carbonitriding, the furnace atmosphere is intentionally rich in specific elements (like carbon or nitrogen). These elements diffuse into the surface of the material, creating a hard, wear-resistant outer layer known as a "case."

Ensuring Uniformity with Air Flow

Controlled air or gas flow within the furnace is essential for maintaining uniform temperatures and atmospheric composition around the entire part. This prevents hot or cold spots and ensures the treatment is applied consistently.

Understanding the Trade-offs

Achieving the perfect heat treatment involves balancing competing priorities. There are always practical and economic trade-offs to consider.

Speed vs. Metallurgical Quality

Faster heating and cooling cycles can increase production throughput, but they also raise the risk of internal stresses, cracking, or incomplete transformation. Slower, more deliberate cycles generally produce higher quality but take more time and energy.

Precision vs. Cost

Achieving extremely tight temperature tolerances (+/- 5°C) and using specialized atmospheres requires sophisticated sensors, control systems, and furnaces. This precision comes at a significantly higher equipment and operational cost.

Equipment and Material Limitations

The heating elements chosen for a furnace dictate its maximum operating temperature. Furthermore, the material itself has limits; exceeding its maximum recommended temperature can permanently damage its metallurgical properties, a condition known as "overheating" or "burning."

Aligning Process Factors with Your Goal

The specific settings for temperature, time, and atmosphere are dictated entirely by the desired outcome for the material.

- If your primary focus is maximizing hardness: You will need precise control over high temperatures followed by a very rapid cooling rate (quenching).

- If your primary focus is improving ductility and relieving stress: You will prioritize slower, more controlled heating and cooling rates (annealing or normalizing).

- If your primary focus is altering only the surface properties: Your critical factor will be the precise composition of the furnace atmosphere to enable case hardening.

Mastering the interplay of these factors is the key to transforming a raw material into a component with predictable, reliable, and enhanced performance.

Summary Table:

| Factor | Key Consideration | Impact on Material |

|---|---|---|

| Temperature Profile | Reaching and holding transformation temperatures | Drives microstructural change (e.g., austenitizing steel) |

| Furnace Atmosphere | Inert (prevents oxidation) or reactive (e.g., carburizing) | Protects surface or alters surface chemistry |

| Heating/Cooling Rates | Speed of temperature change (quenching vs. annealing) | Determines final hardness, ductility, and stress levels |

Ready to achieve precise and repeatable heat treatment results in your lab?

The factors of temperature, atmosphere, and cooling are not just variables—they are the levers of control for your material's final properties. KINTEK specializes in providing the advanced lab furnaces and consumables you need to master this critical process.

Whether your goal is maximum hardness, improved ductility, or specialized surface treatments, our equipment delivers the precision and reliability required for R&D and production.

Contact our experts today to discuss your specific application and find the perfect heat treatment solution for your laboratory. Get in touch via our contact form to get started.

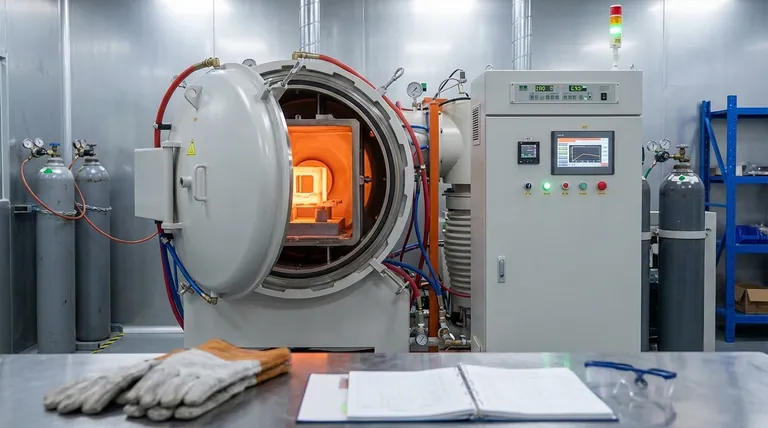

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What role does a high-temperature annealing furnace play in the heat treatment of 316LN? Master Precision Restoration

- What is a furnace classified as? Understand the Two Main Types for Your Application

- What are the two types of quenching? Master Gas vs. Liquid for Superior Heat Treatment

- Why is vacuum drying equipment required for titanium metal slurry? Prevent Oxidation & Structural Defects

- Which factors must be controlled during sintering? Master Temperature, Atmosphere, and Material for Optimal Results

- How does a vacuum environment contribute to TaC densification? Unlock High-Performance Ceramic Sintering

- What temperature is needed for metal casting? Achieve Perfect Casts with the Right Superheat

- Why is a vacuum drying oven necessary for Al-Sn powder slurries? Protect Purity and Accelerate Solvent Removal