At its core, vacuum heat treatment is performed to process metals in a highly controlled environment, free from the oxygen and other atmospheric gases that cause undesirable surface reactions. This prevents issues like oxidation and decarburization, resulting in parts with a superior surface finish, enhanced mechanical properties, and higher consistency straight out of the furnace.

The fundamental problem with traditional heat treatment is that heating metal in air alters its surface and can compromise its integrity. Vacuum heat treatment solves this by removing the atmosphere, ensuring the only changes to the part are the ones you intend.

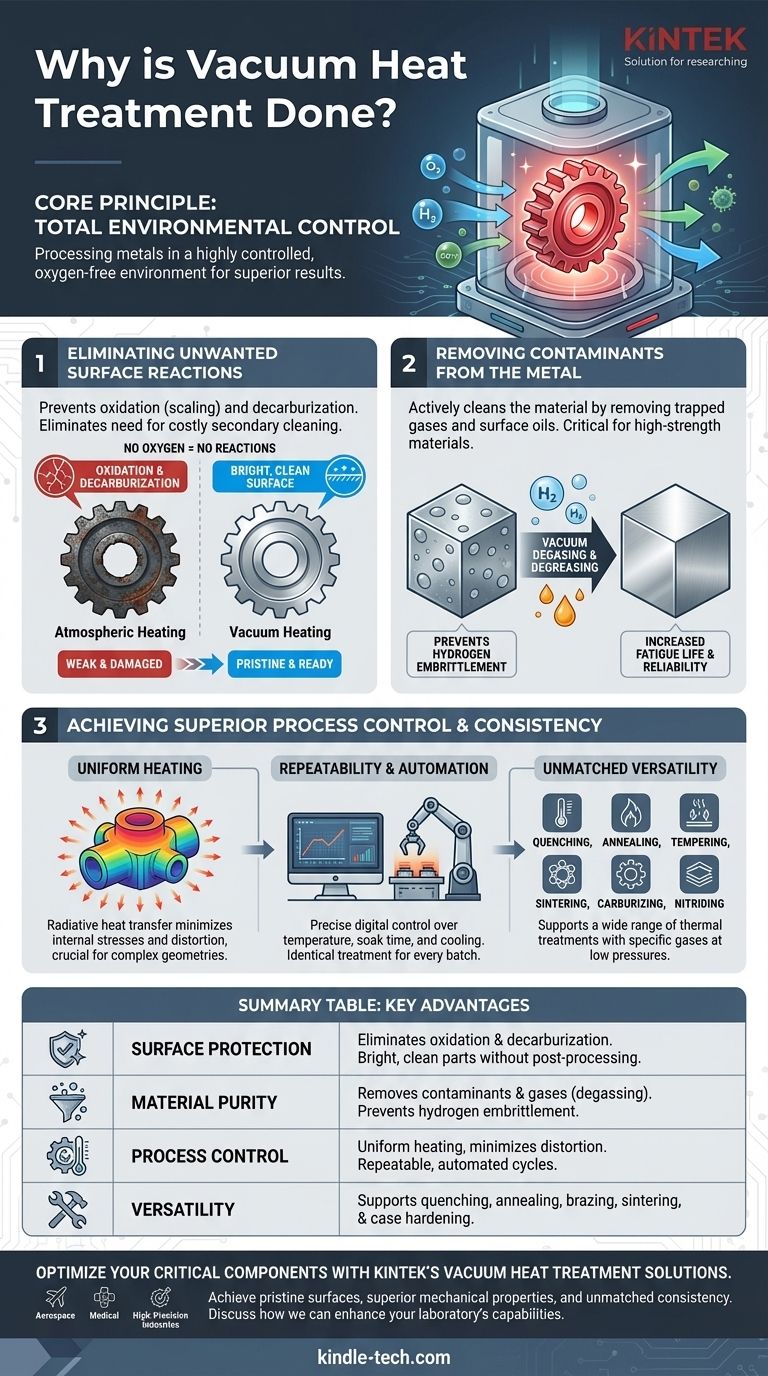

The Core Principle: Total Environmental Control

The defining advantage of a vacuum furnace is its ability to remove the surrounding atmosphere before and during the heating process. This seemingly simple step fundamentally changes the outcome of the treatment.

Eliminating Unwanted Surface Reactions

When steel and other alloys are heated in the presence of air, their surfaces react with the atmosphere. A vacuum eliminates these reactions.

The most common reactions are oxidation (scaling or discoloration) and decarburization. Decarburization is the loss of carbon from the surface of steel, which creates a soft outer layer and severely reduces fatigue life and wear resistance.

By removing the oxygen and other reactive gases, parts emerge from the furnace with a bright, clean surface. This often eliminates the need for costly and time-consuming secondary operations like sandblasting, grinding, or chemical cleaning.

Removing Contaminants from the Metal Itself

A vacuum doesn't just protect the surface; it actively cleans the material. The low-pressure environment effectively pulls contaminants out of the workpiece.

This includes degassing, which removes trapped gases like hydrogen. Removing hydrogen is critical for preventing hydrogen embrittlement, a condition that can cause high-strength materials to fail catastrophically under load.

The vacuum also vaporizes surface oils and residues in a process called degreasing, ensuring a completely clean part prior to the high-temperature cycle.

Achieving Superior Process Control and Consistency

Beyond surface protection, vacuum furnaces offer a level of precision and repeatability that is difficult to achieve with conventional methods.

Uniform Heating and Minimized Distortion

In a vacuum, heat is transferred primarily through radiation, not convection. This allows for extremely uniform heating of the workpiece, even for parts with highly complex geometries.

This uniformity minimizes internal stresses that build up during heating and cooling, significantly reducing distortion and warping. This is critical for high-precision components where maintaining tight tolerances is paramount.

Repeatability and Automation

Vacuum furnace cycles are computer-controlled and highly automated. Critical parameters like temperature, soak time, and cooling rate (gas or oil quenching) are managed with digital precision.

This ensures that every part in a batch, and every subsequent batch, receives the exact same treatment. This process consistency is essential for industries like aerospace, medical, and defense where part reliability is non-negotiable.

Unmatched Versatility

Modern vacuum furnaces are not limited to one type of process. They are incredibly versatile and can be used for a wide range of thermal treatments.

This includes quenching, annealing, tempering, brazing, sintering, and even case hardening processes like carburizing and nitriding by introducing specific gases at precise low pressures.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution for every application. Understanding its limitations is key to making an informed decision.

Higher Initial and Operational Costs

Vacuum furnaces and their associated pumping systems represent a significant capital investment compared to traditional atmospheric furnaces. Their complexity can also lead to higher maintenance costs.

Potentially Longer Cycle Times

The process of pumping the chamber down to the required vacuum level adds time to each cycle. For high-volume, low-cost parts where speed is the priority, this can be a disadvantage.

Process Suitability

While versatile, a vacuum is not always the desired environment. Some heat treatment processes are specifically designed to react with a particular atmosphere, which may be more easily and cheaply accomplished in a conventional furnace.

When to Choose Vacuum Heat Treatment

The decision to use vacuum technology should be driven by the final requirements of your component.

- If your primary focus is pristine surface finish and appearance: Choose vacuum to eliminate oxidation and the need for costly post-processing steps.

- If your primary focus is maximum mechanical performance and fatigue life: Choose vacuum to prevent surface decarburization and remove hydrogen to avoid embrittlement.

- If your primary focus is processing high-value or complex geometry parts: Choose vacuum for its uniform heating, which minimizes distortion and reduces the risk of scrapping expensive components.

- If your primary focus is high-volume, low-cost production with less stringent surface needs: Traditional atmospheric treatment may be a more cost-effective solution.

Ultimately, choosing vacuum heat treatment is an investment in quality, consistency, and the final performance of your critical components.

Summary Table:

| Key Advantage | Description |

|---|---|

| Surface Protection | Eliminates oxidation and decarburization for bright, clean parts without post-processing. |

| Material Purity | Removes contaminants and gases (degassing) to prevent hydrogen embrittlement. |

| Process Control | Ensures uniform heating, minimizes distortion, and offers repeatable, automated cycles. |

| Versatility | Supports quenching, annealing, brazing, sintering, and case hardening processes. |

Optimize your critical components with KINTEK's vacuum heat treatment solutions. Our advanced lab equipment ensures your metals achieve pristine surfaces, superior mechanical properties, and unmatched consistency—ideal for aerospace, medical, and high-precision industries. Contact our experts today to discuss how we can enhance your laboratory's capabilities and meet your specific heat treatment needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is controlled pyrolysis? A Guide to Converting Waste into Valuable Products

- How do vacuum furnaces support MSW pyrolysis? Advanced Experimental Support for Waste-to-Energy

- Why is a high vacuum furnace used for the homogenization of 3D-printed alloy libraries before corrosion testing? - FAQ

- Why is vacuum drying equipment required after wet milling NiCrCoTiV powders? Ensure High Purity & Prevent Oxidation

- What are the effects of sintering on the powder compact produced by pressing? Achieve Strong, Dense Parts

- How do vacuum furnaces heat? Achieve Purity and Precision in High-Temperature Processing

- What is the critical temperature of heat treatment? Unlock the Key to Steel's Hardness and Performance

- What is the carburizing process in heat treatment? Create Wear-Resistant Parts with a Tough Core