Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Sample Preparation

KinTek sample preparation equipment includes sample crushing,milling, as while as while sieving equipment, hydraulic press equipment includes manual press, electric press, isostatic press, hot press and press filtering machine.

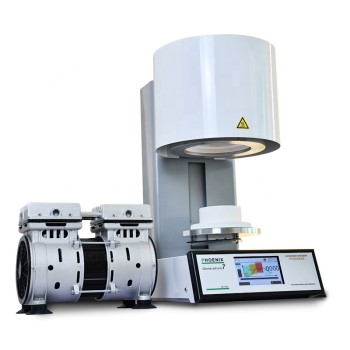

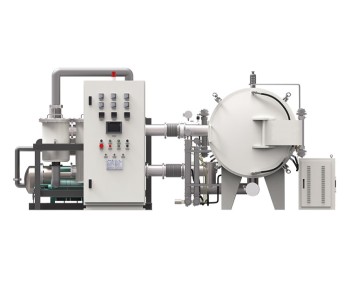

Thermal Equipment

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Lab Consumables & Materials

KinTek offers a range of lab consumables and materials, including evaporation materials, targets, metals, electrochemistry parts, as well as powders, pellets, wires, strips, foils, plates, and more.

Bio-Chem Equipment

KinTek bio-chem equipment comprises rotary evaporators, glass and stainless steel reactors, distillation systems, circulating heaters and chillers, as well as vacuum equipment.

Products

Super Negative Oxygen Ion Generator Machine for Air Purification

Item Number : KT-C03

Button Battery Disassembly and Sealing Mold for Lab Use

Item Number : PCKM

Square Bidirectional Pressure Mold for Lab Use

Item Number : PMS-F

Round Bidirectional Press Mold for Lab

Item Number : PMSY

Cylindrical Press Mold with Scale for Lab

Item Number : PCMC

Anti-Cracking Press Mold for Lab Use

Item Number : PML

Ring Press Mold for Lab Applications

Item Number : PMO

Lab Electrochemical Workstation Potentiostat for Laboratory Use

Item Number : KT-CHIP

Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

Item Number : TPM-06

Battery Lab Equipment Battery Capacity and Comprehensive Tester

Item Number : BC-06

Laboratory Horizontal Autoclave Steam Sterilizer Lab Microcomputer Sterilizer

Item Number : KT-C06

Hexagonal Boron Nitride HBN Spacer Cam Profile and Various Spacer Types

Item Number : KE-D3

VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

Item Number : KT-C02

Laboratory Scientific Electric Heating Blast Drying Oven

Item Number : KT-B05

Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

Item Number : KT-B04

Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

Item Number : KT-B03

Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

Item Number : KT-B02

Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

Item Number : KT-B01

Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

Item Number : KT-Q02

Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

Item Number : KT-Q01

UV Lamp Trolley for Laboratory and Hospital Use

Item Number : KT-P05

Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

Item Number : KT-P03

Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

Item Number : KT-P01

Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

Item Number : KT-P02

Hexagonal Boron Nitride HBN Ceramic Ring

Item Number : KM-D6

Boron Nitride (BN) Ceramic Rod for High Temperature Applications

Item Number : KM-D4

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

The Architecture of Accuracy: Why the Electrolytic Cell Lid is Your Most Critical Interface

There is no universal standard for electrolytic cell lids, though Φ6.2mm and Φ3.2mm are common. Learn why precise aperture configuration is vital for data integrity.

The Architecture of Precision: Why the Invisible Details Define Electrochemical Success

Master the art of pre-use inspection for electrolytic cells. From physical integrity to electrode purity, learn why the invisible details dictate experimental safety.

The Invisible Architecture of Precision: Mastery Before the Current Flows

Achieve electrochemical accuracy by mastering the four pillars of preparation: rigorous inspection, cleaning, installation, and electrolyte management.

The Thermal Ceiling: Pushing 2200°C in Vacuum Environments

Discover how specialized vacuum furnaces achieve 2200°C+ through advanced graphite and tungsten elements. A deep dive into thermal engineering and material limits.

The Glass Heart of the Experiment: Precision Through Systematic Care

Routine maintenance of double-layer electrolytic cells isn't just cleaning—it's calibration. Discover the systematic protocol for reproducible electrochemical data.

The Quiet Physics of Purity: Mastering Heat in a Vacuum

Vacuum furnaces don't just heat; they fundamentally alter physics by replacing convection with radiation. Explore how removing air unlocks material perfection.

Why Your Furnace-Brazed Parts Fail—And Why It's Not the Furnace's Fault

Discover the real reason your furnace brazing results are inconsistent and costly. It's not the equipment; it's a misunderstanding of physics.

The Geometry of Cleanliness: Why Surface Integrity Defines Electrochemical Success

Master the art of electrolytic cell maintenance. Discover how a tiered cleaning protocol prevents contamination and ensures experimental reproducibility.

The Art of Nothingness: Precision and Purity in Vacuum Heat Treatment

Discover the engineering logic behind vacuum furnaces. Learn how eliminating air prevents oxidation, ensures purity, and enables advanced metallurgy.

Entropy and the Alumina Tube: The Art of Precision Maintenance

Discover the disciplined approach to cleaning alumina furnace tubes. Learn how to prevent thermal shock, remove residue with acid, and extend equipment life.

Why Your Heat Treatment Fails: Beyond the Maximum Temperature of Your Vacuum Furnace

Discover why focusing on max temperature leads to failed heat treatments. Learn to match your vacuum furnace to your process for consistent, high-quality results.

The Thermodynamics of Patience: Preventing Electrolytic Cell Overload

Overloading an electrolytic cell isn't just an error; it's a systemic failure. Learn the physics of safety, the risks of excess energy, and how to maintain control.

The Architecture of Certainty: Mastering Control in Multifunctional Electrolytic Cells

Precision in electrochemistry isn't about guesswork; it's about hardware architecture. Learn how the three-electrode system isolates variables for true control.

The Real Reason Your Sintered Parts Crack (And It’s Not the Furnace)

Stop blaming the furnace. Discover the hidden flaw in powder pressing that causes parts to crack and learn how Cold Isostatic Pressing (CIP) offers a permanent fix.

The Architecture of Precision: Mastering the Five-Port Water Bath Electrolytic Cell

Mastering the electrolytic cell is not just about chemistry; it is about discipline. Learn the systematic approach to preparation, operation, and maintenance.

Why Your Heat-Treated Parts Are Failing: The Hidden Enemy in Your Furnace

Seeing inconsistent results from your furnace? Learn why air is the real culprit in heat treatment and how to get perfect, oxide-free parts every time.

The Hidden Life of Lab Equipment: Preserving the Integrity of the Electrolytic Cell

Proper storage is an active defense against entropy. Learn the protocols for maintaining electrolytic cells to ensure data fidelity and equipment longevity.

Beyond the Scale: Why Your Furnace Is Ruining Your Parts—And the Simple Fix

Tired of oxidized, inconsistent heat-treated parts? Discover why the air in your furnace is the real problem and how a vacuum furnace provides the definitive solution.

Why Your Brazed Joints Fail: The Truth About Furnace Temperature and How to Master It

Discover the root cause of inconsistent brazing results. It's not the furnace, but a misunderstanding of how temperature relates to filler metals.

The Silent Interface: Mastery Over Electrode Decay

Electrode failure is rarely sudden; it is the compound interest of neglect. Learn the disciplined maintenance protocols that preserve accuracy and longevity.