The Anatomy of a Flaw

Imagine a turbine blade inside a jet engine. It's a marvel of metallurgy, a single crystal of a superalloy spinning thousands of times per minute while withstanding temperatures that would melt lesser metals.

Its perfection is absolute. Its failure is catastrophic.

The greatest threat to this blade wasn't born in the stress of flight, but in the final moments of its creation: during heat treatment. A single, stray oxygen molecule bonding to its surface, or a tiny, invisible thermal stress from uneven heating, could create a microscopic weak point. In the unforgiving environment of an engine, microscopic flaws become epic failures.

This is the central problem in high-performance material science. It’s not just about making things hot; it’s about creating an environment of absolute control where flaws have no place to hide and no air to breathe.

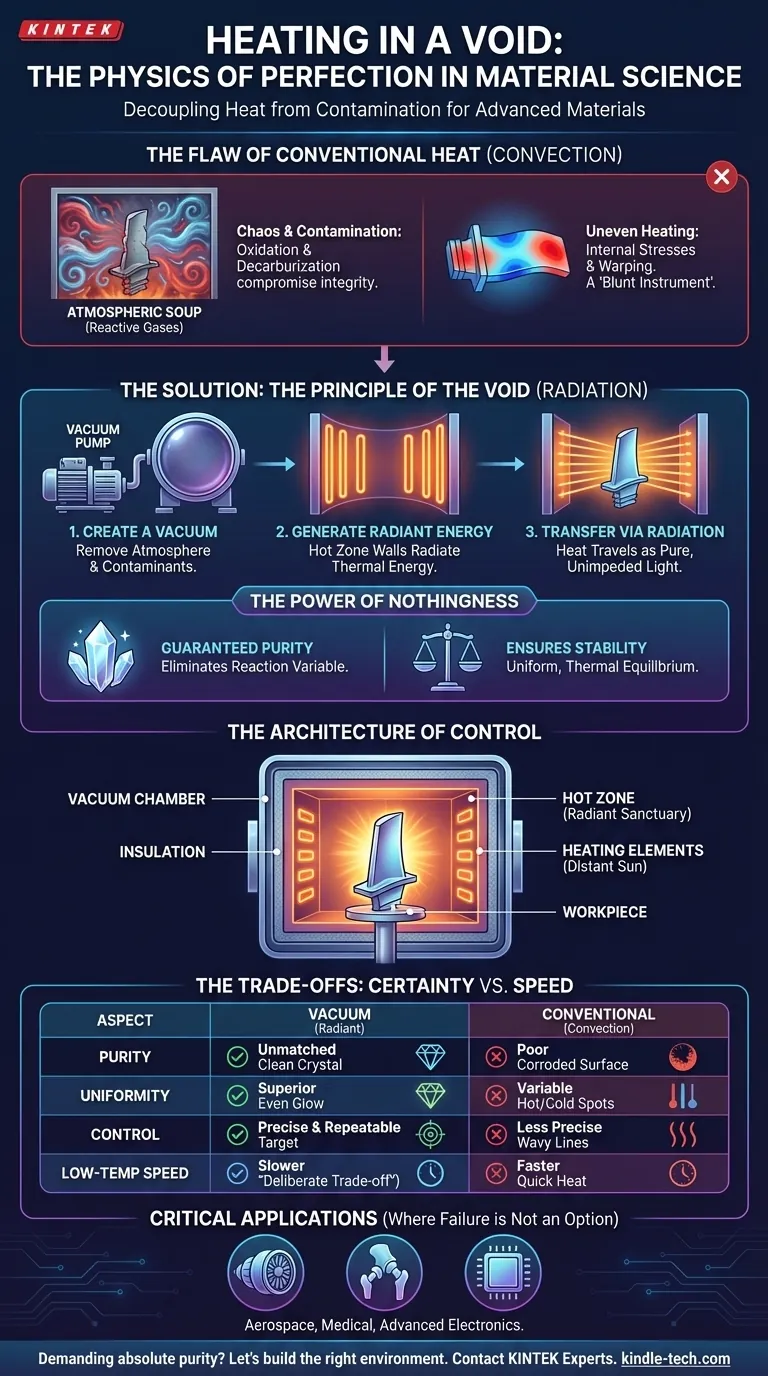

Conventional Heat is a Blunt Instrument

In a standard furnace, heat is transferred by convection. A fan blows hot air around, much like a kitchen oven.

This works for baking bread. It is a disaster for creating turbine blades.

Air is not empty. It's a chaotic soup of oxygen, nitrogen, and other reactive gases. At high temperatures, this soup aggressively attacks the surface of metals, causing oxidation and decarburization—forms of contamination that compromise the material's integrity from the outside in.

Furthermore, circulating air creates hot and cold spots. This uneven heating introduces internal stresses, warping delicate geometries and planting the seeds of future fractures. You can't achieve perfection in a storm.

The Principle of the Void: Decoupling Heat from Contamination

A vacuum furnace operates on a profoundly different, almost elegant, principle. By removing the air, it decouples the heat source from the workpiece.

The core idea is simple: heat is delivered indirectly.

- Create a Vacuum: The chamber is evacuated, removing the atmosphere and all its reactive contaminants.

- Generate Radiant Energy: Electric heating elements warm the furnace's internal walls, the "hot zone."

- Transfer via Radiation: These superheated walls then radiate thermal energy—pure, unimpeded light on the infrared spectrum—onto the parts inside.

The heat doesn't travel through a medium; it travels through a void. This seemingly small change has monumental consequences.

The Power of Nothingness

The vacuum itself is the most critical component. It serves two psychological and physical functions:

- It Guarantees Purity: By removing the air, you remove the variable of atmospheric reaction. You are no longer fighting against contamination; you have eliminated its possibility. This is the difference between filtering dirty water and starting with pure H₂O.

- It Ensures Stability: Without air currents, there is no turbulence. Radiant energy bathes the part evenly from all directions, creating a state of thermal equilibrium that is impossible to achieve with convection.

The Architecture of Control

This principle is embodied in the furnace's design, a system where every component serves the goal of environmental purity and thermal precision.

The Hot Zone: A Radiant Sanctuary

This is the insulated heart of the furnace. It's built from materials with low thermal mass, like rigidized ceramic fiber, allowing it to heat and cool rapidly without retaining excess energy. Its sole purpose is to become a perfect, uniform radiator of heat.

The Heating Elements: The Distant Sun

Positioned around the hot zone, these elements never touch the workpiece. They are the external energy source, the "sun" whose energy will be harnessed. Their separation from the parts is the physical manifestation of decoupling.

The Retort: A Chamber Within a Chamber

In some designs, parts are placed in a sealed container called a retort. The heaters warm the outside of the retort, which then radiates heat to the inside. This "hot wall" design adds another layer of isolation, ensuring the work environment remains pristine.

The Trade-Offs of Perfection

This method isn't about speed; it's about certainty. And this reflects a deeper psychological choice in engineering.

| Aspect | Vacuum Furnace (Radiant Heat) | Conventional Furnace (Convection) |

|---|---|---|

| Purity | Unmatched. Eliminates oxidation & contamination. | Poor. Atmosphere causes surface reactions. |

| Uniformity | Superior. No hot spots, preventing warpage and stress. | Variable. Air currents create uneven temperatures. |

| Control | Precise & Repeatable. Stable environment for complex cycles. | Less Precise. Subject to atmospheric variables. |

| Low-Temp Speed | Slower. Radiation is less efficient at lower temperatures. | Faster. Forced air heats quickly from ambient. |

The slower heat-up at lower temperatures isn't a flaw; it's a deliberate trade-off. It's the price paid for the absolute certainty that when the material reaches its critical transformation temperature, it does so in a perfect, uniform, and sterile environment.

For applications in aerospace, medical implants, or advanced electronics, this isn't just a benefit—it's the only acceptable path. The risks of contamination or thermal stress are too high to leave to chance.

At KINTEK, we understand that advanced materials demand an advanced environment. Our high-performance vacuum furnaces are engineered not just to heat, but to create that controlled void where perfection is possible. For the most demanding applications where failure is not an option, providing a pristine and stable thermal environment is everything.

If your work demands absolute purity and precision, let's build the right environment for it. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

Related Articles

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?