Articles

Operational Guide for Inert Atmosphere Protection Furnace in Mixed Atmosphere

1 year agoDetailed guide on operating an inert atmosphere protection furnace in a mixed atmosphere, emphasizing gas control, safety measures, and process adjustments.

Learn More

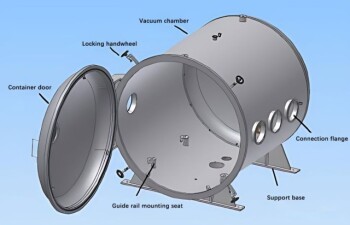

Vacuum Atmosphere Furnaces: High Temperature Processes and Applications

1 year agoAn overview of vacuum atmosphere furnaces, their types, structures, and applications in high-temperature processes.

Learn More

Improving Usage of Atmosphere Furnaces

1 year agoGuidelines and precautions for effective and safe operation of atmosphere furnaces.

Learn More

Understanding Vacuum Atmosphere Furnace Temperature Control and Heat Transfer

1 year agoAn in-depth look at vacuum atmosphere furnace temperature control and the various heat transfer mechanisms.

Learn More

Classification and Characteristics of Controlled Atmosphere Heat Treatment Furnace

1 year agoAn overview of different types and key features of controlled atmosphere heat treatment furnaces.

Learn More

Atmosphere Furnace Gas Monitoring: Importance and Applications

1 year agoDiscusses the necessity and methods of gas monitoring in chamber atmosphere furnaces for various high-temperature processes.

Learn More

Choosing the Right Tube Furnace for Laboratory Use

1 year agoGuidelines on selecting tube furnaces based on temperature, sample size, temperature zones, functions, and vacuum pumps.

Learn More

Understanding Laboratory Tube Furnaces

1 year agoAn in-depth look at the structure, advantages, installation, precautions, and differences between tube and box resistance furnaces.

Learn More

Energy-Saving Benefits of Vacuum Atmosphere Tube Furnaces

1 year agoExploring how vacuum atmosphere tube furnaces optimize energy use through design and operational techniques.

Learn More

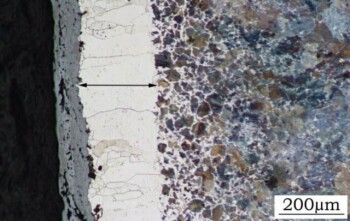

Carrier Materials and Refractory Properties in Vacuum Furnaces

1 year agoAn in-depth look at the materials and refractory properties essential for the operation of vacuum furnaces, including their applications and recommended materials.

Learn More

Vacuum Tube Furnaces: Routine Maintenance and Frequently Asked Questions

1 year agoGuidelines and solutions for maintaining vacuum tube furnaces and addressing common issues.

Learn More

Vacuum Furnace Types and Applications

1 year agoOverview of different vacuum furnace types and their uses in various heat treatment processes.

Learn More

Laboratory Vacuum Furnace Operating Procedures

1 year agoDetailed steps for operating a vacuum furnace in a laboratory setting.

Learn More

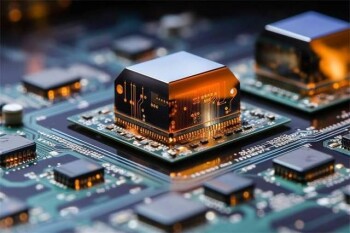

Chip Manufacturing: Comprehensive Guide to the Annealing Process

1 year agoDetailed exploration of the annealing process in semiconductor fabrication, its types, key parameters, and applications.

Learn More

Application of Vacuum Heat Treatment Technology

1 year agoExploring the evolution and benefits of vacuum heat treatment in metal processing.

Learn More

Structural Features and Functions of Vacuum Furnaces in Powder Metallurgy

1 year agoThis article discusses the structural features and functions of vacuum furnaces, focusing on their use in powder metallurgy processes.

Learn More

Advantages of Vacuum Heat Treatment Over Conventional Heat Treatment

1 year agoA detailed comparison highlighting the benefits of vacuum heat treatment in various aspects.

Learn More

Comparison of Common Semiconductor Annealing Processes

1 year agoAn overview of different semiconductor annealing methods and their characteristics.

Learn More

Comprehensive Overview of Commonly Used Heat Treatment Equipment

1 year agoThis article discusses various heat treatment equipment, their classifications, structures, and applications.

Learn More

Vacuum Heat Treatment: Principles and Processes

1 year agoAn overview of vacuum heat treatment methods to improve material properties.

Learn More

Guidelines for Purchasing Vacuum Heat Treatment Furnaces

1 year agoA comprehensive guide on selecting and purchasing vacuum heat treatment furnaces for various industrial applications.

Learn More

Technical Characteristics and General Knowledge of Vacuum Heat Treatment Furnaces

1 year agoAn in-depth look at the technical aspects and general knowledge of vacuum heat treatment furnaces, focusing on their unique features and operational requirements.

Learn More

High-Temperature Vacuum Furnace: Classification, Applications, and Components

1 year agoAn overview of high-temperature vacuum furnaces, their types, applications, and key components.

Learn More

Applications and Advances in Vacuum Hot Press Sintering Furnaces for Precision Ceramics

1 year agoExplores the use of vacuum hot press sintering for advanced ceramics, metal/ceramic welding, and industry trends.

Learn More

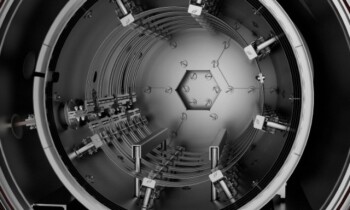

Functions of a Vacuum Hot Press Sintering Furnace

1 year agoExploring the key functions of vacuum hot press sintering furnaces in material processing.

Learn More

Advanced Ceramics Hot Press Sintering Technology and Equipment

1 year agoExplores the hot press sintering process for advanced ceramics, its methods, advantages, equipment, and applications.

Learn More

Vacuum Hot Press Sintering Furnace Structure and Classification

1 year agoAn in-depth look at the structure, types, and components of vacuum hot press sintering furnaces, focusing on their applications and benefits in material densification.

Learn More

Common Sense Points for Vacuum Heat Treatment

1 year agoKey considerations and practices in vacuum heat treatment processes.

Learn More

Principles and Applications of Vacuum Hot Press Sintering Equipment

1 year agoExploring the principles, classification, and applications of vacuum hot press sintering equipment in materials science.

Learn More

Understanding Hot Presses and Safety Considerations

1 year agoAn overview of hot presses, their applications, advantages, and safety precautions.

Learn More