Articles

Laboratory Sample Preparation and Digestion Equipment

1 year agoOverview of essential lab equipment for sample preparation and digestion.

Learn More

Basic Cleaning and Disinfection Equipment in the Laboratory

1 year agoOverview of essential lab cleaning and disinfection tools and their operational principles.

Learn More

Basic Laboratory Extraction Equipment

1 year agoOverview of various extraction methods used in laboratories.

Learn More

Basic Laboratory Purification Equipment Overview

1 year agoAn overview of essential purification equipment used in laboratories, including water purification, solvent evaporation, and waste treatment systems.

Learn More

Basic Mixing Equipment in the Laboratory

1 year agoOverview of essential laboratory mixing devices and their functionalities.

Learn More

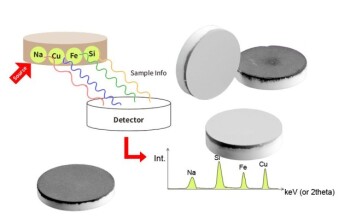

Sample Preparation Methods in X-ray Fluorescence and Their Impact on Test Results

1 year agoExplores the tablet and melting methods in X-ray fluorescence, detailing their advantages, disadvantages, and key considerations.

Learn More

Preparation Techniques for Solid Samples in Infrared Spectroscopy

1 year agoA detailed guide on various methods for preparing solid samples for infrared spectroscopy, including plate pressing, paste, and thin film methods.

Learn More

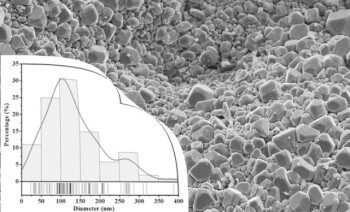

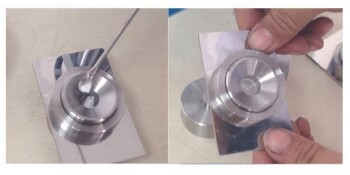

X-ray Fluorescence Spectrometry: Powder Tableting Sample Preparation

1 year agoA comprehensive guide on the powder tableting method for sample preparation in X-ray fluorescence spectrometry, detailing grinding, pressing, and application scope.

Learn More

IR (Tablet Pressing Method) Operation

1 year agoDetailed guide on the IR tablet pressing method, including instruments, reagents, sample preparation, and testing procedures.

Learn More

Issues with Poor Demoulding in Manual Tablet Presses

1 year agoAnalyzes the causes of poor demoulding in manual tablet presses, focusing on powder, mold, machine body, and operator factors.

Learn More

X-ray Fluorescence Spectrometry Analysis Method | Sample preparation method: tableting sample preparation

1 year agoDetailed guide on XRF analysis, focusing on sample preparation and powder sample methods.

Learn More

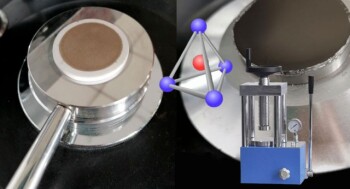

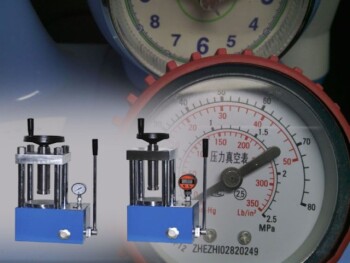

Manual Lab Hydraulic Pellet Press: Comprehensive Guide to High-Quality Pellet Preparation

1 year agoExplore the detailed guide on using a Manual Lab Hydraulic Pellet Press for high-quality pellet preparation in spectral analyses. Learn about features, operation, and maintenance for optimal performance.

Learn More

Optimizing Laboratory Analysis with Split Automatic Heated Lab Pellet Press

1 year agoExplore the advanced features and benefits of split automatic heated lab pellet presses for precise pellet preparation in various analytical applications. Ideal for high-throughput laboratories.

Learn More

Electric Lab Cold Isostatic Press (CIP): Applications, Benefits, and Customization

1 year agoExplore the versatile world of Electric Lab Cold Isostatic Press (CIP) technology. Learn about its applications in various industries, benefits, and customization options for tailored solutions.

Learn More

Exploring the Capabilities and Applications of Warm Isostatic Pressing (WIP)

1 year agoDive into the comprehensive guide on Warm Isostatic Pressing (WIP), its technology, applications, and benefits in material processing. Discover how WIP enhances material properties and its role in advanced manufacturing.

Learn More

Why Most PELLET PRESS XRF SAMPLE PREPARATION Fail: Common Issues and Solutions

1 year agoDiscover the common pitfalls in PELLET PRESS XRF SAMPLE PREPARATION and learn effective solutions to ensure accurate results. Covers particle size, contamination, binder choice, and more.

Learn More

Manual Hydraulic Presses for Laboratory Use: A Comprehensive Guide

1 year agoExplore the intricacies of manual hydraulic presses in labs, including operation, benefits, and comparison with automatic models. Ideal for those seeking detailed insights on sample preparation and cost-effectiveness.

Learn More

Mastering XRF Sample Preparation: 7 Proven PRESS Strategies for Optimal Results

1 year agoElevate your XRF analysis with 7 advanced PRESS strategies. Learn expert tips for successful XRF pellet pressing, optimal sample preparation, and consistent results.

Learn More

Hydraulic Heated Lab Pellet Press: Comprehensive Guide to Selection and Usage

1 year agoExplore the features and applications of hydraulic heated lab pellet presses. Learn how to choose the right model for your research needs and maximize efficiency in material science labs.

Learn More

Comprehensive Guide to Integrated Manual Heated Lab Pellet Presses

1 year agoExplore the features and applications of integrated manual heated lab pellet presses. Learn about customization options, capacities, and benefits for spectroscopy and analysis.

Learn More

Manual Pellet Press: A Comprehensive Guide to Efficient Lab Pelletizing

1 year agoExplore the intricacies of manual pellet presses, including operation, safety, and maintenance tips. Learn how to choose the right press, understand force gauges, and optimize pellet quality for your lab experiments.

Learn More

Hydraulic Tablet Press: Comprehensive Guide to Design, Operation, and Applications

1 year agoExplore the advanced features, operational principles, and diverse applications of hydraulic tablet presses in various industries. Learn how these machines ensure high-quality tablet production with detailed insights.

Learn More

Comprehensive Guide to Spark Plasma Sintering Furnaces: Applications, Features, and Benefits

1 year agoExplore the advanced features and applications of Spark Plasma Sintering Furnaces (SPS) in material science. Learn how SPS technology offers rapid, efficient, and versatile sintering for various materials.

Learn More

Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

1 year agoExplore the advanced features and applications of molybdenum vacuum furnaces in high-temperature sintering and material treatment. Learn about their construction, control systems, and maintenance tips.

Learn More

Ultimate Guide to High Pressure Tube Furnaces: Applications, Types, and Benefits

1 year agoExplore the comprehensive guide to high pressure tube furnaces, including their applications in materials science, types such as horizontal and vertical, and key benefits for precise high-temperature processes.

Learn More

Comprehensive Guide to Muffle Furnaces: Types, Uses, and Maintenance

1 year agoExplore the world of muffle furnaces with our detailed guide. Learn about their types, applications in various industries, and essential maintenance tips to ensure optimal performance.

Learn More

Comprehensive Guide to Metal Mold Pressing: Techniques, Equipment, and Applications

1 year agoExplore the detailed process of metal mold pressing, including equipment, techniques, and applications. Learn how hydraulic presses shape materials like metal and rubber efficiently.

Learn More

Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment

1 year agoExplore the advanced features and applications of molybdenum vacuum furnaces in high-temperature sintering and heat treatment. Learn about their construction, control systems, and maintenance tips.

Learn More

High Pressure Tube Furnace: Applications, Safety, and Maintenance

1 year agoExplore the advanced applications, safety measures, and maintenance tips for high pressure tube furnaces. Learn how these furnaces are used in various high-temperature processes and ensure optimal performance and safety.

Learn More

Controlled Atmosphere Furnace: Comprehensive Guide to Advanced Heat Treatment

1 year agoExplore the advanced features and applications of controlled atmosphere furnaces in heat treatment processes. Learn about key components, operational techniques, and benefits for precise material processing.

Learn More