Step into the future of laboratory technology with the fully automatic isostatic press – a powerhouse of efficiency and precision. Designed for high-end laboratories, its programmed pressurization and user-friendly operation redefine the standards of laboratory equipment. Join us as we unveil the steps of split isostatic pressing, where small size meets strong pressure in a cost-effective package, catering to diverse laboratory needs.

Split isostatic pressing operation steps

1.Place the sample into the isostatic chamber.

2.Press the "Set" key. Enter the settings menu.

3.Enter the settings menu.

4.Press the "+" key to increase the setting value.

5.Press the "-" key to reduce the setting value.

6.Press the "Settings" button to enter the next setting.

7.Press the "Settings" key repeatedly to return to the operation interface.

8.When pressurizing, press the "Stop" button to terminate the pressurization.

9.Press the "Preparation" key to start pressurization.

10.Add the equipment to the set pressure and maintain the pressure for a period of time

11.Loosen the lead screw.

12.Remove the isostatic chamber.

13.Loosen the bleed screw on the pressure rod on the cavity.

14.Turn the demoulding screw and take out the upper pressure rod.

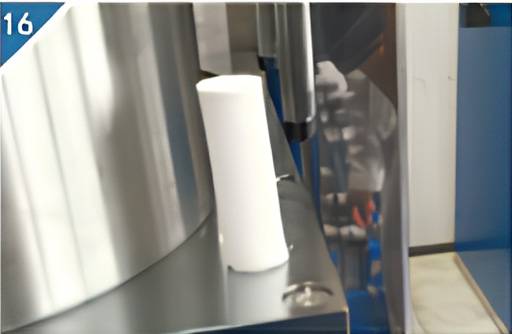

15.Remove the rubber mold.

16.Remove the sample.

Concluding our exploration of the steps of split isostatic pressing with the fully automatic press, it becomes evident that this compact marvel is a game-changer. Its small size and robust pressure capabilities offer high cost performance, making it a versatile choice for laboratories. The LCD display adds an intuitive touch to the operation, enhancing clarity for users. In the realm of laboratory technology, the fully automatic isostatic press sets a new benchmark, where efficiency and precision

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press for Solid State Battery Research

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

Related Articles

- Uniformity Over Form: The Hidden Genius of Cold Isostatic Pressing

- How Isostatic Presses Improve the Efficiency of Material Processing

- Hot & Cold Isostatic Pressing: Applications, Process, and Specifications

- Understanding Cold Isostatic Pressing and Its Applications

- Electric Lab Cold Isostatic Press (CIP): Applications, Benefits, and Customization