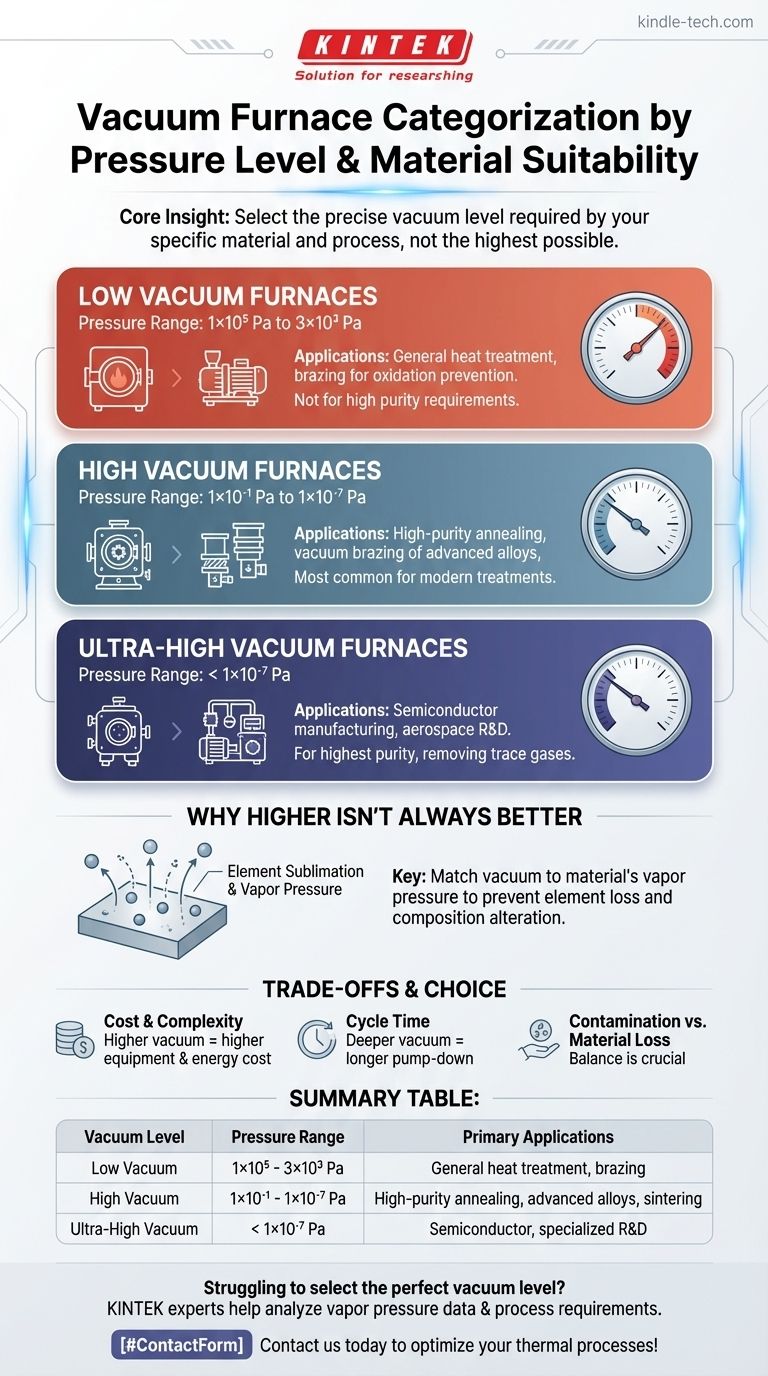

At its core, a vacuum furnace's classification is defined by the minimum pressure level, or degree of vacuum, it can reliably achieve and maintain. These furnaces are generally categorized into three primary types: low vacuum, high vacuum, and ultra-high vacuum, each suited for different materials and thermal processes.

The critical insight is not to pursue the highest vacuum possible, but to select the precise vacuum level required by your specific material and process. An excessively high vacuum can be as damaging as an insufficient one, causing essential alloy elements to evaporate from your workpiece.

The Tiers of Vacuum Furnaces

The working vacuum level of a furnace dictates its capabilities, complexity, and ideal applications. The pressure is typically measured in Pascals (Pa).

Low Vacuum Furnaces

A low vacuum system generally operates in the pressure range of 1×10⁵ Pa down to 3×10³ Pa.

These furnaces are suitable for general-purpose heat treatment and brazing processes where the primary goal is to prevent heavy oxidation, but the material's purity requirements are not exceptionally stringent.

High Vacuum Furnaces

High vacuum systems operate in a much lower pressure range, typically from 1×10⁻¹ Pa down to 1×10⁻⁷ Pa.

This is the most common category for demanding applications like high-purity annealing, vacuum brazing of advanced alloys, and sintering. The vast majority of modern vacuum heat treatments occur within this range, as it effectively eliminates gas contamination for sensitive materials.

Ultra-High Vacuum Furnaces

This category represents the most advanced systems, designed for specialized research and manufacturing where even trace amounts of gaseous molecules can compromise the outcome.

These furnaces achieve exceptionally low pressures, ensuring the highest possible purity in the processing environment for materials used in sectors like semiconductor manufacturing and aerospace.

Why "Higher Vacuum" Isn't Always Better

Choosing a vacuum furnace is not a matter of simply picking the one with the lowest pressure rating. The selection is a precise engineering decision based on the physics of your material at high temperatures.

The Principle of Vapor Pressure

Every element has a vapor pressure, which is the pressure at which it will begin to turn into a gas at a given temperature. As you heat a material, the vapor pressure of its constituent elements increases.

The Risk of Element Sublimation

If the pressure inside the furnace (the vacuum level) drops below the vapor pressure of an element in your workpiece, that element will begin to sublimate or evaporate.

This means the element literally boils off the surface and is pumped out by the vacuum system. This can alter the chemical composition of your alloy, degrading its mechanical properties and ruining the part.

Matching Vacuum to Material

The ideal vacuum level is low enough to remove unwanted atmospheric gases (like oxygen) but high enough to remain above the vapor pressure of your material's essential elements at the target process temperature.

Understanding the Trade-offs

Selecting an inappropriate vacuum level has significant practical and financial consequences.

The Cost of a Deeper Vacuum

Achieving and maintaining high or ultra-high vacuum requires more sophisticated and expensive equipment, including multi-stage pump systems (like diffusion or turbomolecular pumps). This increases capital cost, energy consumption, and maintenance complexity.

The Impact on Cycle Time

Pumping down to a lower pressure takes significantly more time, extending the overall process cycle. For many applications, the marginal benefit of a slightly deeper vacuum does not justify the added time and operational cost.

Contamination vs. Material Loss

The core trade-off is a balance. You need a vacuum sufficient to prevent reactions with atmospheric contaminants, but not so deep that you begin to lose the material itself. This is the central challenge in vacuum metallurgy.

How to Make the Right Choice

Your process requirements should be the sole driver of your furnace specification. Use these guidelines to inform your decision.

- If your primary focus is general heat treatment or brazing of common alloys: A low or medium-vacuum furnace is often the most cost-effective and efficient choice.

- If your primary focus is high-purity processing of reactive or advanced materials (e.g., titanium, superalloys): A high-vacuum furnace is non-negotiable to prevent gas contamination and ensure optimal material properties.

- If your primary focus is preventing element loss in specific alloys at high temperatures: You must carefully consult the material's vapor pressure data to set a minimum pressure target for your process.

Ultimately, selecting the right vacuum furnace is about defining your material's precise needs and choosing the tool that meets them without unnecessary excess.

Summary Table:

| Vacuum Level | Pressure Range | Primary Applications |

|---|---|---|

| Low Vacuum | 1×10⁵ Pa to 3×10³ Pa | General heat treatment, brazing where oxidation prevention is key |

| High Vacuum | 1×10⁻¹ Pa to 1×10⁻⁷ Pa | High-purity annealing, vacuum brazing of advanced alloys, sintering |

| Ultra-High Vacuum | < 1×10⁻⁷ Pa | Semiconductor manufacturing, specialized aerospace R&D |

Struggling to select the perfect vacuum level for your lab's materials?

Choosing the wrong vacuum furnace can lead to material loss, contamination, or unnecessary costs. KINTEK specializes in lab equipment and consumables, serving precise laboratory needs. Our experts will help you analyze your material's vapor pressure data and process requirements to recommend the ideal vacuum furnace that ensures purity without compromising your alloy's integrity.

Contact us today via our [#ContactForm] to optimize your thermal processes and protect your valuable materials!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance