In essence, a pharmaceutical reactor is a highly controlled, sophisticated vessel designed for one primary purpose: to precisely manage chemical reactions. It is not merely a container, but an active instrument that manipulates variables like temperature, pressure, and mixing to synthesize a target molecule, most often the Active Pharmaceutical Ingredient (API), which is the therapeutic substance in a drug. By providing this stable and predictable environment, reactors accelerate reaction speed and ensure the final product is both pure and consistent.

A pharmaceutical reactor's true function is to solve the immense challenge of scalability and repeatability. It bridges the gap between a small-scale laboratory discovery and large-scale, safe, and consistent manufacturing, transforming a chemical blueprint into a reliable medicine.

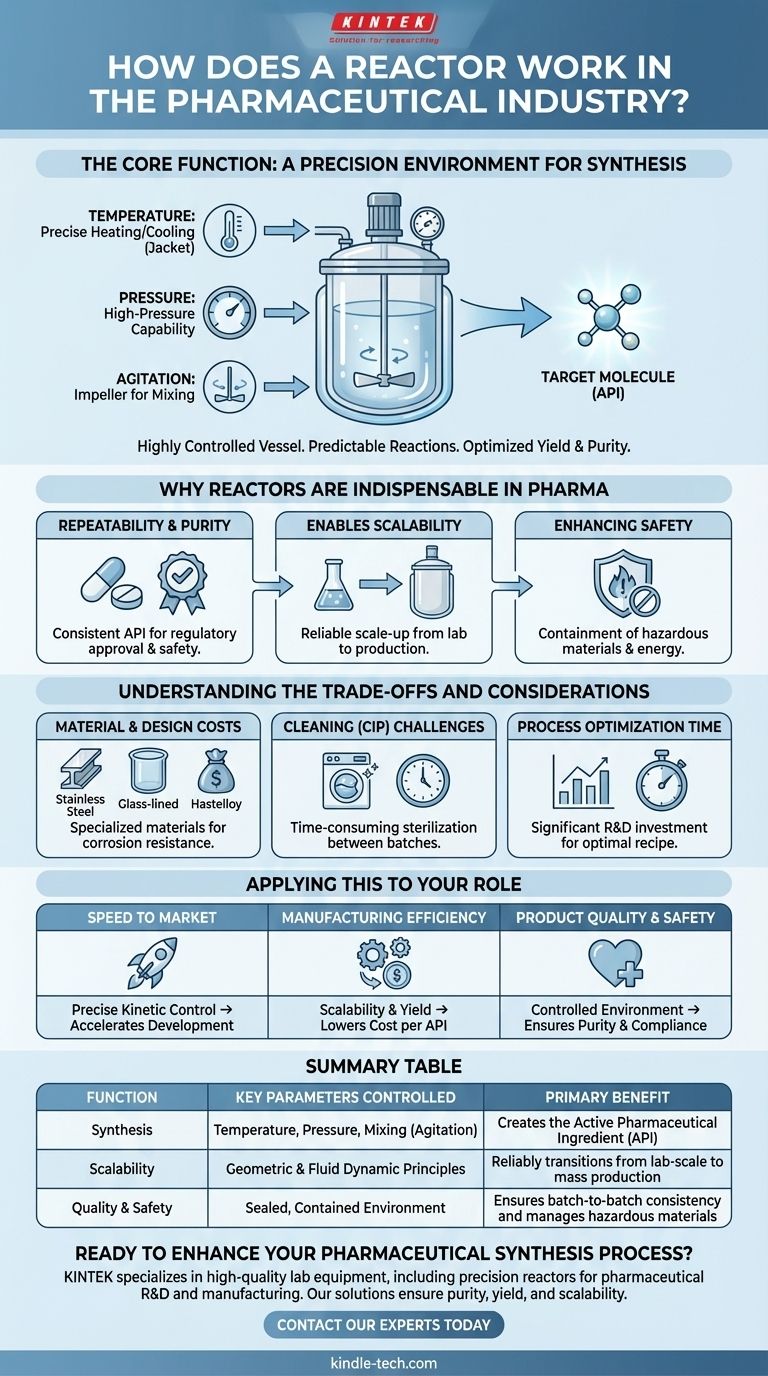

The Core Function: A Precision Environment for Synthesis

A reactor is the operational heart of chemical synthesis in the pharmaceutical industry. Its entire design is focused on creating an ideal, repeatable environment for molecules to combine in a predictable way.

The Concept of a Controlled Vessel

At its core, a reactor contains and controls a chemical reaction. Unlike a simple beaker in a lab, it is a sealed system that allows operators to dictate the exact conditions inside. This control is what ensures the reaction produces the desired molecule (yield) with minimal unwanted byproducts (purity).

Key Parameters Under Control

The "magic" of a reactor lies in its ability to precisely manage several key physical parameters, each critical for guiding a chemical reaction.

- Temperature: Many reactions are highly sensitive to heat. A reactor's jacketing system allows for precise heating or cooling, ensuring the reaction proceeds at the optimal rate without causing decomposition or unwanted side reactions.

- Pressure: As the reference material notes, some reactions require high pressure to force molecules together and increase the reaction speed. A high-pressure reactor is built to safely contain these forces, drastically reducing the time needed for synthesis.

- Agitation (Mixing): An internal impeller or agitator ensures all reactants are evenly distributed. Proper mixing improves heat transfer and ensures molecules come into contact, leading to a more efficient and complete reaction.

Why Reactors Are Indispensable in Pharma

The transition from discovering a drug molecule to manufacturing millions of doses is fraught with scientific and engineering challenges. The reactor is the primary tool for overcoming these hurdles.

Ensuring Repeatability and Purity

Every single batch of a drug must be chemically identical to the last. A reactor's precise control system guarantees that the exact same conditions are applied every time, resulting in a consistent API. This repeatability is a non-negotiable requirement for regulatory approval and patient safety.

Enabling Scalability

A reaction that works in a 100-milliliter flask may behave completely differently in a 10,000-liter vessel. Reactors are designed with geometric and fluid dynamic principles that allow chemists and engineers to reliably scale up a process from the lab bench to full-scale production without fundamentally changing the reaction's outcome.

Enhancing Safety

Pharmaceutical reactions can sometimes be volatile, releasing large amounts of energy (exothermic) or involving hazardous materials. A reactor is a containment vessel designed to manage these risks, preventing runaway reactions and protecting operators and the environment.

Understanding the Trade-offs and Considerations

While essential, implementing and operating reactors involves significant strategic decisions and operational challenges.

Material and Design Costs

Reactors are not one-size-fits-all. They are constructed from specialized materials like stainless steel, glass-lined steel, or exotic alloys like Hastelloy depending on the corrosiveness of the chemicals involved. The cost of these highly engineered, specialized vessels is substantial.

The Challenge of Cleaning and Sterilization

Between batches of different products, a reactor must be meticulously cleaned to prevent cross-contamination. This process, known as Clean-In-Place (CIP), is time-consuming and resource-intensive, representing a significant portion of a plant's operational downtime.

Process Optimization Time

Finding the perfect "recipe" of temperature, pressure, and agitation for a new drug is a major part of process development. This optimization phase requires significant investment in time and expertise to maximize yield and purity before manufacturing can begin at scale.

Applying This to Your Role

Understanding the reactor's function allows you to better contextualize its impact across different business and scientific goals.

- If your primary focus is Speed to Market: The reactor's ability to provide precise kinetic control directly accelerates process development and validation, shortening the critical path from clinical trials to commercial launch.

- If your primary focus is Manufacturing Efficiency: The reactor is the key to scalability and high yield, which directly lowers the cost per kilogram of the API and improves overall plant profitability.

- If your primary focus is Product Quality and Safety: The reactor's controlled environment is the ultimate guarantee of product purity and consistency, which is fundamental to regulatory compliance and patient well-being.

Ultimately, the pharmaceutical reactor is the powerful engine that reliably and safely converts the promise of chemistry into the reality of modern medicine.

Summary Table:

| Function | Key Parameters Controlled | Primary Benefit |

|---|---|---|

| Synthesis | Temperature, Pressure, Mixing (Agitation) | Creates the Active Pharmaceutical Ingredient (API) |

| Scalability | Geometric & Fluid Dynamic Principles | Reliably transitions from lab-scale to mass production |

| Quality & Safety | Sealed, Contained Environment | Ensures batch-to-batch consistency and manages hazardous materials |

Ready to enhance your pharmaceutical synthesis process?

KINTEK specializes in high-quality lab equipment and consumables, including precision reactors designed for the demanding needs of pharmaceutical R&D and manufacturing. Our solutions help you achieve superior control over your reactions, ensuring the purity, yield, and scalability required to bring life-saving drugs to market efficiently and safely.

Contact our experts today to discuss how our reactor technology can power your next breakthrough.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the advantages of a chemical reactor? Unlock Precision, Efficiency, and Safety in Your Process

- What is a high pressure autoclave? A Complete Guide to High-Temp, High-Pressure Reactors

- How is high pressure generated in an autoclave? Unlock the Science of Sterilization & Synthesis

- How high pressure is created in a lab? Master Safe and Precise Pressure Generation

- What are autoclaves used in the chemical industry? High-Pressure Reactors for Synthesis & Curing