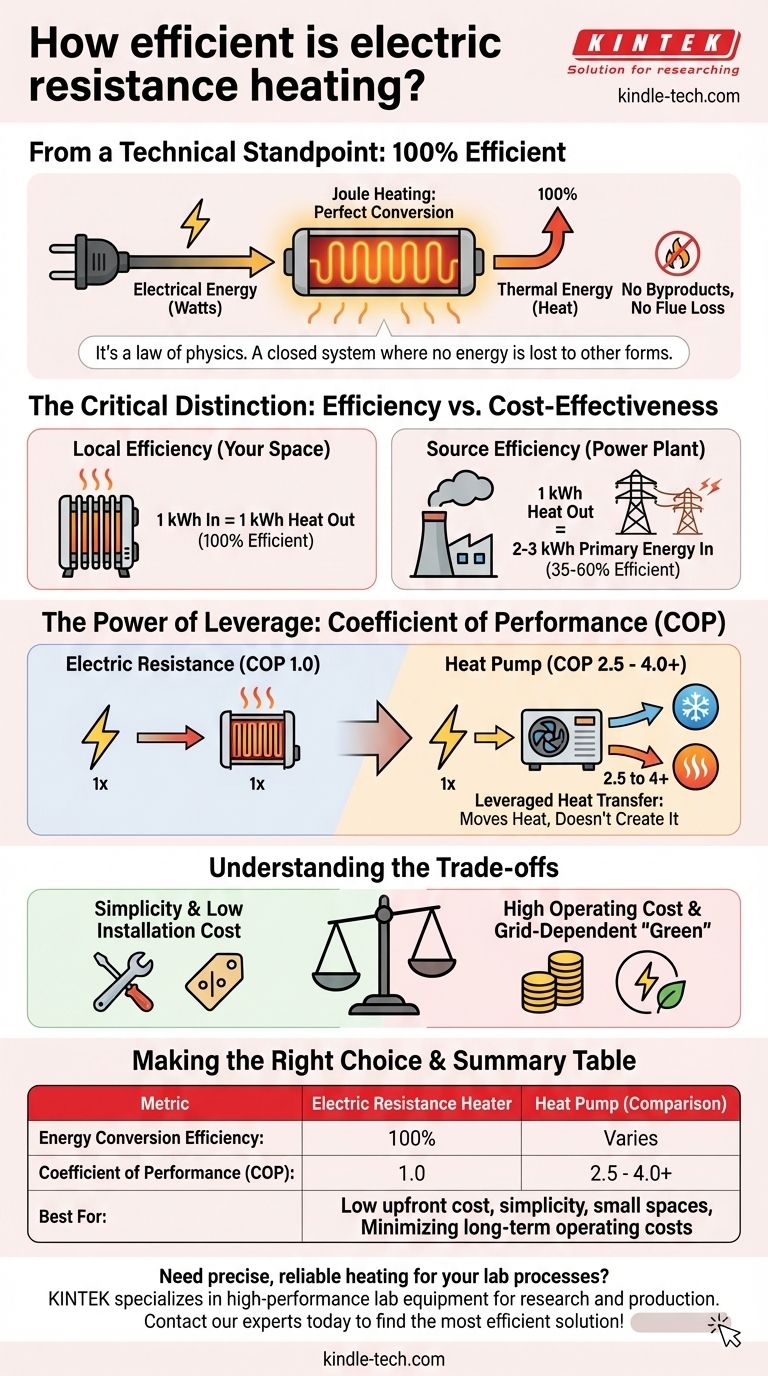

From a technical standpoint, electric resistance heating is 100% efficient. Every single watt of electrical energy drawn by the heater is converted directly into thermal energy, or heat. This perfect conversion is a fundamental principle of physics.

While electric resistance heating flawlessly converts electricity to heat, its overall efficiency and cost-effectiveness are determined by how the electricity was generated and the availability of more leveraged technologies like heat pumps.

How Electric Resistance Achieves 100% Efficiency

The perfect efficiency of electric resistance heat is not a marketing claim but a law of physics. It's a closed system where no energy is lost to other forms like light or motion.

The Principle of Joule Heating

Electric resistance heaters work by forcing an electric current through a material that resists its flow, such as a nichrome wire. As electrons collide with the atoms of the resistive material, their kinetic energy is converted directly into heat.

This process, known as Joule heating, ensures that all the electrical energy consumed is dissipated as thermal energy. There are no chemical reactions or mechanical byproducts where energy can be lost.

No Byproducts, Only Heat

Unlike a gas furnace that loses a significant percentage of its heat up a flue pipe along with exhaust gases, a resistance heater has no flue and no exhaust. One hundred percent of the heat it produces is delivered directly to the surrounding space.

The Critical Distinction: Efficiency vs. Cost-Effectiveness

The term "100% efficient" can be misleading if you're trying to determine the most economical way to heat a space. The real question is not how well the device converts electricity to heat, but the total cost and energy required to deliver that heat.

Local Efficiency vs. Source Efficiency

While the heater in your room is 100% efficient, the power plant that generated the electricity is not. A natural gas power plant might be 35-60% efficient, and a coal plant is often less.

This means that for every 1 kWh of heat you get in your home, it may have taken 2-3 kWh of primary energy (like natural gas or coal) to produce and transmit that electricity.

The Power of Leverage: Coefficient of Performance (COP)

The most important metric for comparing heating systems is the Coefficient of Performance (COP). COP measures how many units of heat are delivered for each unit of energy consumed.

By definition, an electric resistance heater has a COP of 1.0. It delivers exactly one unit of heat for every one unit of electricity it uses.

In contrast, a heat pump doesn't create heat; it moves it. By using a refrigerant cycle, it can extract heat from the outside air (even when it's cold) and move it inside. This process allows it to achieve a COP of 2.5 to 4.0 or higher, making it 250% to 400% more efficient than resistance heating.

Understanding the Trade-offs

Choosing electric resistance heat involves balancing its inherent simplicity against its high operating costs in most scenarios.

Pro: Simplicity and Low Installation Cost

Resistance heaters are mechanically simple, containing little more than a heating element and a fan. This makes them reliable, durable, and very inexpensive to purchase and install.

Con: High Operating Cost

Because its COP is only 1.0, resistance heating produces the least amount of heat per dollar spent on electricity. In almost all climates, running a heat pump or a natural gas furnace will result in significantly lower monthly energy bills.

Con: The "Green" Question

The environmental impact of electric heat is tied directly to your local power grid. If your electricity comes from solar, wind, or hydro, then resistance heating is a zero-emission solution at the point of use. If your grid is powered by fossil fuels, its upstream carbon footprint can be substantial.

Making the Right Choice for Your Goal

The "best" heating solution depends entirely on your specific application and priorities.

- If your primary focus is low upfront cost and simplicity: Electric resistance is an excellent choice for small spaces, supplemental heating, or areas used infrequently.

- If your primary focus is minimizing long-term operating costs: A high-efficiency heat pump is almost always the superior choice, delivering 2.5 to 4 times more heat for the same electrical cost.

- If your primary focus is advanced industrial processes: Alternative methods like electromagnetic heating may offer even greater speed and energy savings compared to traditional resistance wire.

Ultimately, understanding that 100% electrical efficiency does not equal low cost is the key to making an informed decision.

Summary Table:

| Metric | Electric Resistance Heater | Heat Pump (Comparison) |

|---|---|---|

| Energy Conversion Efficiency | 100% | Varies |

| Coefficient of Performance (COP) | 1.0 | 2.5 - 4.0+ |

| Best For | Low upfront cost, simplicity, small spaces | Minimizing long-term operating costs |

Need precise, reliable heating for your lab processes? KINTEK specializes in high-performance lab equipment, including electric resistance furnaces and ovens that deliver accurate temperature control and durability for your research and production needs. Contact our experts today to find the most efficient and cost-effective heating solution for your laboratory!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

People Also Ask

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance