For large-scale production of high-quality graphene, the most prominent and widely adopted method is Chemical Vapor Deposition (CVD). This "bottom-up" technique involves growing a continuous, single-atom-thick film of carbon atoms onto a metal substrate. Unlike methods that break down graphite, CVD allows for the precise creation of large, uniform sheets required for advanced electronics and industrial applications.

While several methods exist to produce graphene materials, only Chemical Vapor Deposition (CVD) consistently resolves the challenge of creating high-quality, large-area films, making it the cornerstone of industrial-scale production for electronic and optical applications.

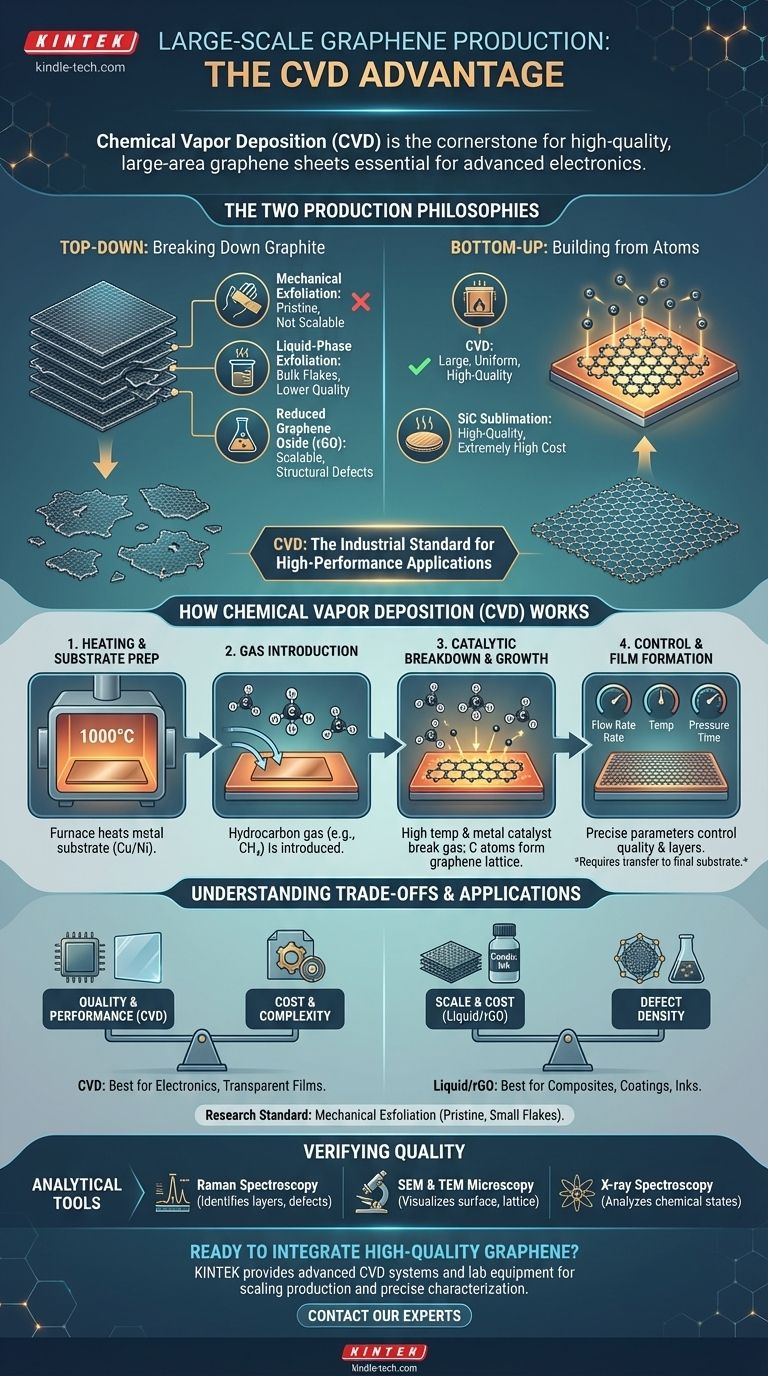

The Two Fundamental Approaches to Graphene Production

Understanding graphene production begins with recognizing two opposing philosophies: breaking a large material down ("top-down") or building the desired material up from individual atoms ("bottom-up").

The "Top-Down" Approach: Breaking Down Graphite

This category includes methods that start with graphite—essentially stacked layers of graphene—and separate those layers.

Mechanical exfoliation is the original method, famously using adhesive tape to peel layers from graphite. It produces pristine, high-quality graphene but is not scalable beyond laboratory research.

Liquid-phase exfoliation involves suspending graphite in a liquid and using energy (like sonication) to break the layers apart. This can produce large quantities of graphene flakes but results in lower electrical quality, making it more suitable for composites and inks than electronics.

Reduction of graphene oxide (GO) is another scalable "top-down" method. It involves chemically oxidizing graphite, exfoliating it into graphene oxide, and then removing the oxygen. However, the process leaves behind structural defects, compromising the material's properties.

The "Bottom-Up" Approach: Building from Atoms

This approach constructs the graphene lattice atom by atom, offering superior control over the final product's quality and uniformity.

Chemical Vapor Deposition (CVD) is the leading "bottom-up" technique. It excels at creating large, continuous sheets of high-quality graphene, which is why it is the focus for industrial applications.

Sublimation of silicon carbide (SiC) is another high-temperature method where silicon is heated until it evaporates from the surface of a SiC wafer, leaving a layer of carbon atoms that rearrange into graphene. While it produces high-quality material, the extremely high cost of SiC wafers limits its widespread use.

How Chemical Vapor Deposition (CVD) Works

The CVD process is a highly controlled growth technique performed inside a specialized furnace.

The Core Process

First, a substrate, typically a thin foil of a transition metal like copper or nickel, is placed inside a reaction chamber. The chamber is heated to a very high temperature, often around 1000°C.

Hydrocarbon Gas Introduction

A carbon-containing gas, such as methane (CH₄), is then introduced into the chamber. The high temperature acts as a catalyst, breaking the hydrocarbon gas molecules down into their constituent atoms.

Graphene Film Formation

The free carbon atoms deposit onto the surface of the hot metal substrate. They naturally arrange themselves into the hexagonal lattice structure of graphene, forming a continuous, single-atom-thick film that can cover the entire surface of the foil.

Controlling Quality and Thickness

Engineers can precisely control the final product by adjusting process parameters. The gas flow rate, temperature, pressure, and exposure time all influence the quality and number of graphene layers formed.

Understanding the Trade-offs

No single production method is perfect for every application. The choice involves balancing quality, scale, and cost.

CVD: Quality vs. Complexity

The primary advantage of CVD is its ability to produce large, uniform, high-quality graphene sheets suitable for electronics. The main drawback is the process complexity and the need to transfer the graphene film from its metal growth substrate to a final target substrate, which can introduce defects if not done carefully.

Exfoliation: Scale vs. Defect Density

Liquid-phase exfoliation is excellent for bulk production of graphene flakes at a lower cost. However, the resulting material has more structural defects and a smaller flake size, limiting its performance in applications that demand pristine electrical conductivity.

Reduced Graphene Oxide: Cost vs. Purity

The GO reduction method is highly scalable and cost-effective. The significant trade-off is purity. The chemical process invariably leaves behind residual oxygen and other defects, which severely disrupt the graphene's electrical properties.

Verifying the Quality of Graphene

Regardless of the production method, the final material must be analyzed to confirm its properties. This is critical for ensuring consistency and performance.

Raman Spectroscopy

This is the most common and powerful technique for characterizing graphene. It can quickly identify the material, confirm the number of layers, and provide a quantitative measure of its structural defects.

Electron Microscopy (SEM & TEM)

Scanning Electron Microscopy (SEM) is used to examine the surface topography of the graphene film, revealing wrinkles, folds, or tears. Transmission Electron Microscopy (TEM) provides a much higher resolution, allowing for the visualization of the atomic lattice itself.

X-ray Spectroscopy

This method analyzes the chemical states within the material. It is particularly useful for verifying the removal of oxygen in reduced graphene oxide or detecting other contaminants.

Making the Right Choice for Your Application

Selecting a production method depends entirely on the end goal and the specific properties required.

- If your primary focus is high-performance electronics or large-area transparent films: CVD is the only viable method for producing the required quality and uniformity at scale.

- If your primary focus is bulk production for composites, conductive inks, or coatings: Liquid-phase exfoliation or the reduction of graphene oxide offers a more cost-effective path where pristine electrical quality is not the main priority.

- If your primary focus is fundamental research requiring flawless samples: Mechanical exfoliation remains the gold standard for producing small, pristine graphene flakes for laboratory study.

Ultimately, the choice of production method is dictated by a direct trade-off between the required quality of the graphene and the acceptable cost of its production.

Summary Table:

| Method | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Chemical Vapor Deposition (CVD) | Electronics, Transparent Films | Large, uniform, high-quality sheets | Complex process, requires transfer |

| Liquid-Phase Exfoliation | Composites, Conductive Inks | Bulk production, cost-effective | Lower electrical quality, defects |

| Reduced Graphene Oxide (rGO) | Coatings, Energy Storage | Highly scalable, low cost | Significant defects, poor conductivity |

| Silicon Carbide Sublimation | Research, High-Frequency Devices | High-quality material | Extremely high cost, limited scalability |

Ready to integrate high-quality graphene into your research or production line?

At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for cutting-edge material science. Whether you are scaling up your graphene production with CVD systems or characterizing your materials with precision analytical tools, our expertise can help you achieve consistent, high-quality results.

Contact us today to discuss how our solutions can accelerate your graphene innovation. Get in touch with our experts

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty