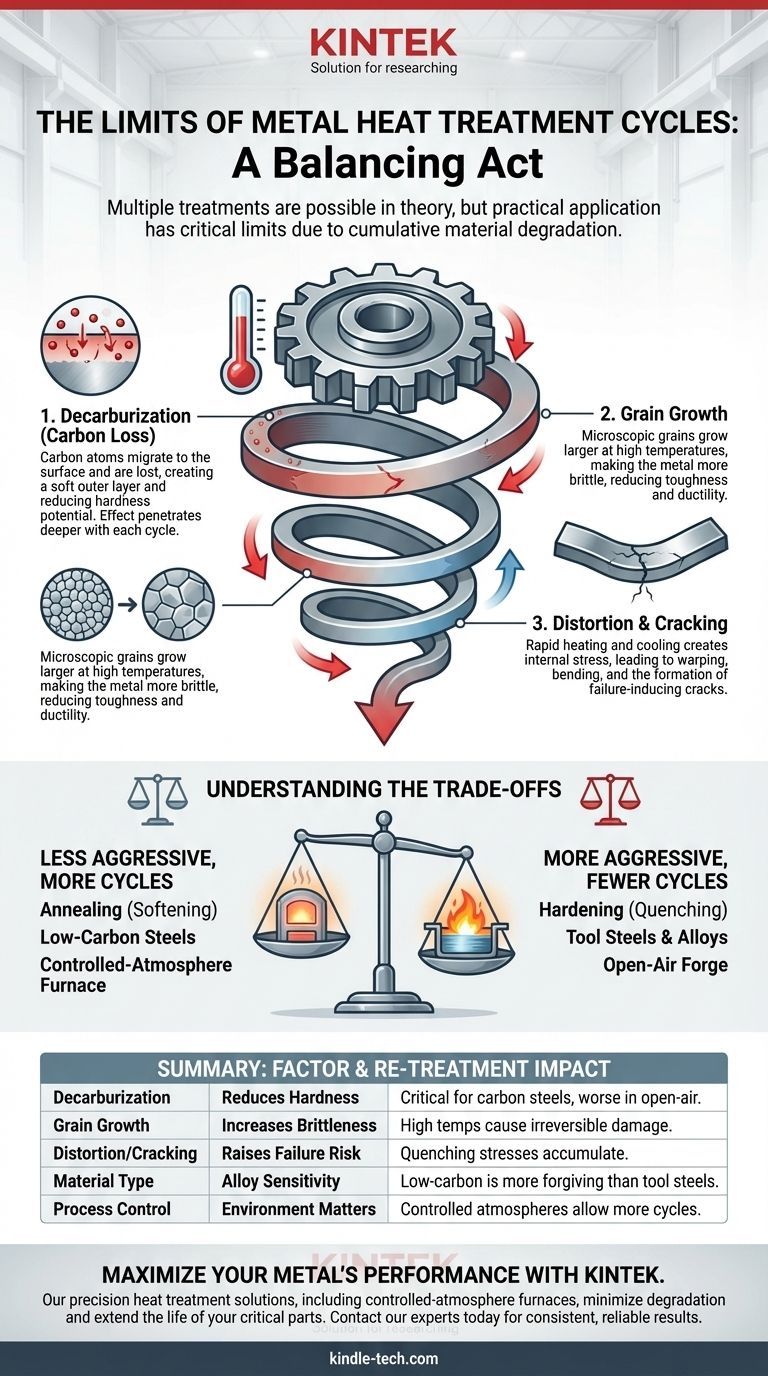

In theory, a piece of metal can be heat-treated multiple times, but in practice, there are critical limits. The exact number of cycles is not a fixed value; it depends entirely on the type of metal, the specific process used, and the acceptable level of degradation. Each heating and cooling cycle introduces cumulative effects like carbon loss, grain growth, and dimensional distortion, which progressively reduce the material's performance and integrity.

While heat treatment can be repeated to fix errors or alter properties, each cycle should be viewed as a form of controlled damage. The real question is not "how many times," but "at what point do the cumulative negative effects outweigh the benefits of another treatment?"

The Purpose of Heat Treatment: A Quick Refresher

Enhancing Mechanical Properties

Heat treatment is the process of using controlled heating and cooling to alter a metal's internal crystalline structure, also known as its microstructure. As your reference notes, this is done to achieve specific, desirable properties.

The goal is to improve characteristics like hardness, strength, toughness, ductility, and wear resistance to make a component suitable for its intended application.

The Microstructure is Key

Processes like annealing (softening), quenching (hardening), and tempering (toughening) are all designed to manipulate this internal structure. A successful heat treatment creates the ideal microstructure for a given job. The problems with repeated treatments arise because each cycle can introduce unintended and undesirable changes to this very structure.

Why You Can't Heat Treat Indefinitely

Every time you heat metal to a critical temperature, you risk introducing permanent, often negative, changes. These effects are cumulative.

The Problem of Decarburization (Carbon Loss)

For steels, carbon content is what allows the metal to harden. When heated in the presence of oxygen (like in an open-air forge or an improperly controlled furnace), carbon atoms migrate to the surface and are lost to the atmosphere.

This decarburization creates a soft "skin" on the part. With each subsequent heat cycle, this effect penetrates deeper, reducing the metal's ability to achieve its target hardness and compromising its wear resistance.

The Risk of Grain Growth

When held at high temperatures, the microscopic crystals (or "grains") that form the metal's structure tend to grow larger. Excessive grain growth is generally undesirable, as it can significantly reduce the metal's toughness and ductility, making it more brittle and prone to fracture.

While a subsequent normalizing cycle can sometimes refine grain structure, repeated, poorly controlled heating will inevitably lead to a coarser, weaker microstructure.

The Challenge of Dimensional Distortion and Cracking

The rapid heating and cooling associated with hardening creates immense internal stress within the material. This stress is what can cause a part to warp, bend, or distort.

Repeating this process adds to the cumulative internal stress. This not only increases the risk of further distortion but can also lead to the formation of micro-cracks, which act as failure points when the part is put under load.

Understanding the Trade-offs

The viability of re-heat treatment is a balancing act. You must weigh the desired outcome against the inevitable material degradation.

Annealing vs. Hardening Cycles

Annealing, which involves a slow cooling process to soften metal, is generally less aggressive than hardening. A part can typically withstand more annealing cycles than the extreme thermal shock of rapid quenching required for hardening.

Material Type Matters

Simple, low-carbon steels are more forgiving of repeated heating than complex alloys. High-carbon and tool steels are especially sensitive; their carefully balanced chemistry is easily disrupted by issues like decarburization, making repeated hardening a significant risk to their performance. Non-ferrous metals like aluminum alloys have their own strict limits related to aging and precipitation hardening.

The Importance of Process Control

The environment in which heat treatment occurs is critical. Using a controlled-atmosphere furnace (such as a vacuum or argon environment) can drastically reduce or eliminate decarburization and surface scaling. Parts treated in such a precise environment can often endure more cycles than those heated in an open-air forge.

Making the Right Choice for Your Goal

The number of viable heat treatment cycles depends entirely on your material, your equipment, and your objective.

- If your primary focus is salvaging a part by re-annealing and re-machining: This is often possible for one or two cycles, but inspect carefully for cracks and account for material loss from scaling.

- If your primary focus is maximizing the performance of a tool steel: Limit hardening and tempering to a single, successful cycle. Each additional attempt will likely degrade its potential hardness, edge retention, and toughness.

- If your primary focus is stress-relieving a welded fabrication: This can typically be done multiple times, as the temperatures are lower and less damaging than a full hardening cycle.

- If your primary focus is correcting a botched hardening process: A second attempt is common, but a third is a significant gamble. Expect a measurable drop in potential performance and a higher risk of cracking.

Ultimately, you must treat each heat treatment cycle as a calculated withdrawal from the material's finite bank of integrity.

Summary Table:

| Factor | Impact on Re-Treatment | Key Consideration |

|---|---|---|

| Decarburization | Reduces hardness potential | Critical for carbon steels; worse in open-air furnaces |

| Grain Growth | Increases brittleness | High temperatures cause irreversible microstructural damage |

| Distortion/Cracking | Raises failure risk | Quenching stresses accumulate with each cycle |

| Material Type | Low-carbon steels are more forgiving than tool steels | Alloy complexity dictates sensitivity |

| Process Control | Controlled-atmosphere furnaces allow more cycles | Vacuum/argon environments minimize degradation |

Maximize your metal's performance with precision heat treatment solutions from KINTEK. Whether you're working with tool steels, alloys, or fabricated components, our advanced lab equipment ensures controlled environments to minimize decarburization and distortion. Contact our experts today to discuss how our furnaces and consumables can help you achieve consistent, reliable results—extending the life and integrity of your critical parts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is a vacuum furnace used for? Unlock High-Purity Heat Treatment for Superior Materials

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service