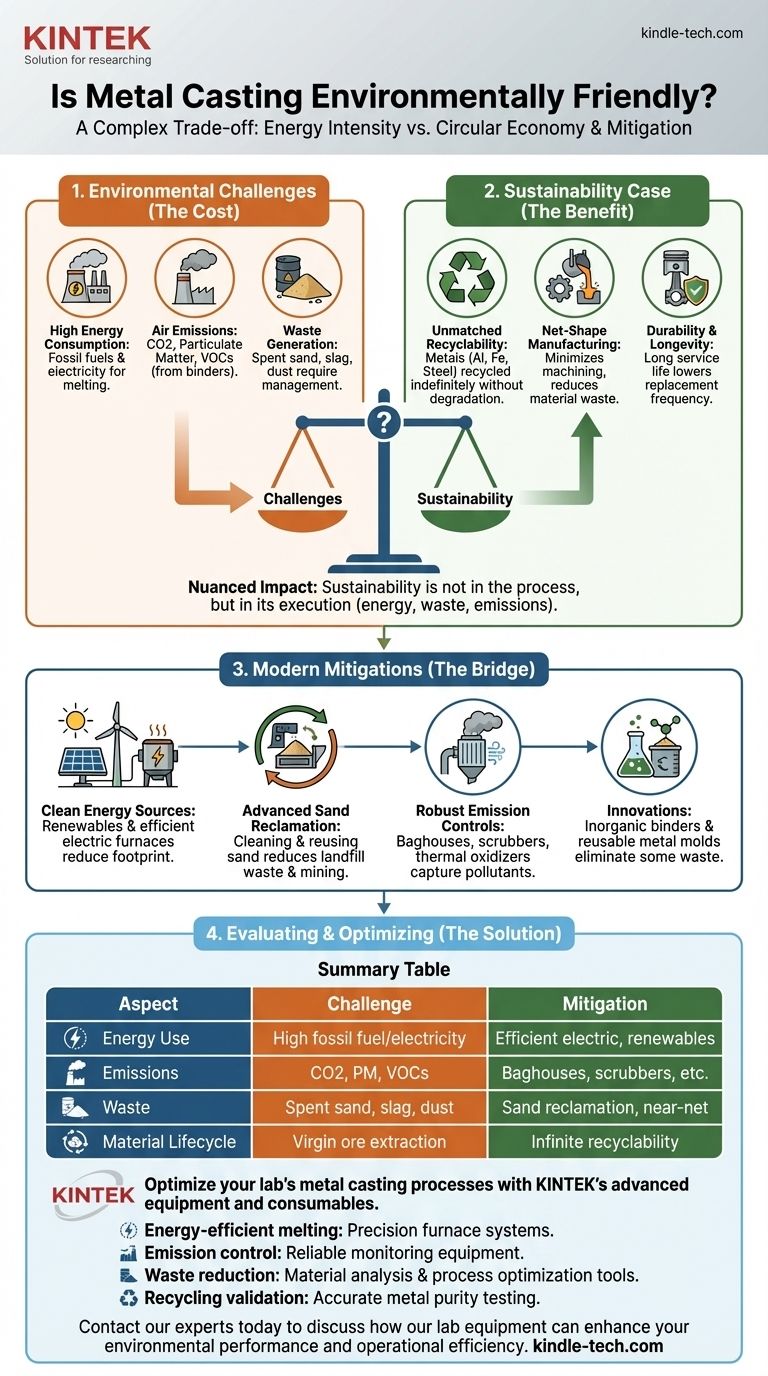

Inherently, no industrial process is truly "environmentally friendly," and metal casting is no exception. It is an energy-intensive process with significant environmental impacts related to emissions, energy consumption, and waste. However, the unique and near-infinite recyclability of metals, combined with modern pollution controls and process efficiencies, makes its environmental profile highly nuanced.

The environmental impact of metal casting is a direct trade-off between its high energy consumption and its unparalleled ability to recycle scrap material into high-value, durable products. Therefore, its sustainability is not determined by the process itself, but by the specific energy sources, waste management systems, and emission controls a foundry employs.

The Primary Environmental Impacts of Metal Casting

To understand the environmental footprint of casting, we must first break down its core operational challenges. Each step, from melting to finishing, presents a distinct impact.

High Energy Consumption

Melting metal requires enormous amounts of thermal energy. This is the single largest factor in casting's environmental impact.

This energy is typically supplied by the combustion of fossil fuels (like natural gas or coke for iron foundries) or by electricity. The carbon footprint of the casting is therefore directly tied to the carbon intensity of its energy source.

Air Emissions

The high-temperature processes involved in casting can generate several types of air pollutants.

Key emissions include carbon dioxide (CO2) from fuel combustion, particulate matter (dust and metal fumes), and volatile organic compounds (VOCs). VOCs are often released from the thermal breakdown of chemical binders used to create sand molds.

Waste Generation

The casting process generates several waste streams that require careful management.

For sand casting, spent sand is the largest volume of waste. While clean sand is non-hazardous, sand mixed with binders and metal residue must be managed properly. Other waste products include slag (impurities skimmed from the molten metal) and dust collected from emission control systems.

The Countervailing Case for Casting's Sustainability

Despite its challenges, metal casting possesses powerful characteristics that contribute positively to a circular economy. Ignoring these aspects provides an incomplete picture.

Unmatched Recyclability

This is casting's greatest environmental strength. Metals like aluminum, iron, steel, and copper can be recycled almost indefinitely without degrading their structural properties.

Foundries are fundamentally recycling operations, transforming scrap metal—from old cars to manufacturing byproducts—into new, complex, and critical components. This drastically reduces the need for virgin ore extraction, which is itself an environmentally destructive process.

Net-Shape Manufacturing

Casting excels at producing complex parts very close to their final dimensions, a concept known as "near-net-shape" manufacturing.

This minimizes the need for subsequent machining, which saves significant energy and, most importantly, reduces material waste. Instead of cutting away 50% of a solid block of metal to create a part, casting creates the shape directly.

Durability and Longevity

Cast metal parts are renowned for their strength and long service life. Components used in engines, infrastructure, and heavy machinery often last for decades.

This inherent durability reduces the frequency of replacement, lowering the overall lifecycle impact of the products they are a part of.

Understanding the Trade-offs and Modern Mitigations

The gap between a "dirty" foundry of the past and a modern, responsible one is vast. The difference lies in the deliberate adoption of mitigation technologies and strategies.

The Critical Role of the Energy Source

A foundry powered by electricity from a grid dominated by renewables (solar, wind, hydro) has a dramatically lower carbon footprint than one burning coke or natural gas. The choice of furnace technology—such as efficient electric induction furnaces versus traditional cupolas—is a defining factor.

Advanced Sand Reclamation

Modern foundries no longer view sand as a disposable commodity. They invest in sand reclamation systems that mechanically or thermally clean used sand, allowing it to be reused dozens of times. This massively reduces landfill waste and the need to mine and transport new sand.

Robust Emission Controls

Effective pollution control is standard practice in modern, compliant foundries. Technologies like baghouses capture particulate matter, while scrubbers and thermal oxidizers can destroy harmful VOCs before they are released into the atmosphere.

Innovations in Materials and Processes

The industry is continuously evolving. New inorganic binders are being developed that release water vapor instead of harmful VOCs when heated. Furthermore, processes like die casting or permanent mold casting use reusable metal molds, eliminating sand waste entirely for certain applications.

How to Evaluate the Environmental Footprint of a Casting Supplier

When sourcing cast components, the focus should shift from the general process to the specific practices of the supplier. Asking the right questions is key to making a responsible choice.

- If your primary focus is reducing carbon footprint: Prioritize foundries that are transparent about their energy sources and can demonstrate investments in high-efficiency melting technologies.

- If your primary focus is a circular economy: Ask for the percentage of recycled content in their products and inquire about their sand reclamation capabilities.

- If your primary focus is air quality and regulatory compliance: Verify that the foundry employs modern emission control technologies and operates well within its environmental permits.

- If your primary focus is overall lifecycle impact: Leverage the benefits of near-net-shape casting to reduce material waste and energy consumption in your own downstream manufacturing processes.

Ultimately, a sustainable metal casting strategy is achieved not by avoiding the process, but by actively selecting partners committed to modern, responsible manufacturing.

Summary Table:

| Aspect | Environmental Challenge | Sustainable Mitigation |

|---|---|---|

| Energy Use | High fossil fuel/electricity consumption | Efficient electric furnaces; renewable energy sources |

| Emissions | CO2, particulate matter, VOCs from binders | Baghouses, scrubbers, thermal oxidizers |

| Waste | Spent sand, slag, dust | Advanced sand reclamation; near-net-shape casting |

| Material Lifecycle | Virgin ore extraction impact | Near-infinite metal recyclability; high recycled content |

Optimize your lab's metal casting processes with KINTEK's advanced equipment and consumables.

As a leading supplier of lab equipment, KINTEK helps foundries and research facilities minimize environmental impact while maximizing efficiency. Our products support:

- Energy-efficient melting with precision furnace systems

- Emission control through reliable laboratory monitoring equipment

- Waste reduction with tools for material analysis and process optimization

- Recycling validation with accurate testing instruments for metal purity

Whether you're developing new casting alloys, improving sand reclamation, or implementing cleaner production methods, KINTEK provides the laboratory solutions you need to make metal casting more sustainable.

Contact our experts today to discuss how our lab equipment can enhance your environmental performance and operational efficiency.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the function of a high-temperature furnace during burnout? Master Aluminum Foam Production with Precision

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What is a rotary heat type furnace? The Ultimate Guide to Uniform Heating & Mixing

- What is a rotary retort furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- What is the process of zirconium production? From Ore to High-Performance Metal & Ceramic