At its core, steel heat treatment is a process of controlled heating and cooling used to manipulate the metal's internal structure and achieve specific, desired properties. The four principal types of heat treatment are hardening, tempering, annealing, and normalizing. Each of these processes alters the steel's mechanical characteristics, such as its strength, toughness, and ductility, to suit a particular application.

Understanding steel heat treatment isn't about memorizing four terms; it's about recognizing that you are fundamentally managing a trade-off between properties, most notably hardness (resistance to wear) and toughness (resistance to fracture).

The Four Core Processes and Their Purpose

Each of the four main heat treatments follows a unique cycle of heating, holding at temperature, and cooling. The most critical factor differentiating them is the rate of cooling, which directly controls the final internal structure of the steel.

Hardening: Maximizing Strength

Hardening is designed to make steel as hard and strong as possible.

The process involves heating the steel to a high temperature (above its critical point) and then cooling it with extreme rapidity. This rapid cooling, known as quenching, is often done in water, oil, or brine.

This traps the steel's internal structure in a very hard, brittle state called martensite. While exceptionally strong, a part that is only hardened is often too brittle for practical use.

Tempering: Relieving Brittleness

Tempering is almost always performed immediately after hardening. It is a crucial secondary step to reduce brittleness.

The process involves reheating the previously hardened steel to a much lower temperature and holding it for a specific time before allowing it to cool.

Tempering sacrifices some of the extreme hardness gained during quenching in exchange for a significant increase in toughness. This makes the steel more durable and less likely to shatter under impact or stress.

Annealing: The Ultimate "Reset"

Annealing produces steel in its softest, most ductile, and most easily machinable state.

This process involves heating steel to a specific temperature and then cooling it as slowly as possible, often by leaving it inside the insulated furnace to cool over many hours or even days.

The goal of annealing is to relieve internal stresses, soften the metal, and refine its grain structure. This makes the steel much easier to cut, shape, or form in subsequent manufacturing steps.

Normalizing: Refining the Structure

Normalizing is a process used to create a more uniform and desirable grain size within the steel.

It involves heating the steel above its critical temperature and then allowing it to cool in still air at room temperature. This cooling rate is faster than annealing but much slower than quenching for hardening.

Normalizing results in a material that is stronger and harder than annealed steel but more ductile than hardened steel. It is often performed to prepare a steel for further heat treatment processes like hardening and tempering.

Understanding the Core Trade-off: Hardness vs. Toughness

To effectively choose a heat treatment, you must understand the properties you are trying to balance. For steel, the most common trade-off is between hardness and toughness.

What is Hardness?

Hardness is the material's ability to resist surface indentation, scratching, and wear. A hard steel, like that in a file or a knife-edge, will hold its shape against abrasion.

What is Toughness?

Toughness is the material's ability to absorb energy and deform without fracturing. A tough steel, like that in a car axle or a wrench, can withstand sudden impacts and shocks. It is the opposite of brittleness.

The Inverse Relationship

Generally, as you make steel harder, you also make it more brittle (less tough). The extreme hardness achieved through quenching comes at the cost of extreme brittleness.

Tempering is the essential process for managing this relationship. By carefully reheating a hardened part, you strategically "trade" some of its peak hardness to regain the toughness needed for it to survive in its real-world application.

Matching the Process to Your Goal

Your choice of heat treatment is dictated entirely by the final properties your component requires.

- If your primary focus is maximum wear resistance: You will use hardening to create a hard surface, followed by tempering to ensure the part doesn't crack in service.

- If your primary focus is easy machining or forming: You will use annealing to put the steel in its softest and most stress-free state before manufacturing.

- If your primary focus is a uniform, strong starting structure: You will use normalizing to refine the grain structure, often as a preliminary step before hardening.

- If your primary focus is making a hardened part functional: You will use tempering to reduce brittleness and add the toughness required to withstand impact and stress.

Ultimately, these four treatments are the tools you use to precisely dial in the mechanical properties your steel needs for its intended purpose.

Summary Table:

| Process | Key Goal | Cooling Method | Key Property Achieved |

|---|---|---|---|

| Hardening | Maximum Strength | Rapid Quenching | High Hardness (Brittle) |

| Tempering | Reduce Brittleness | Low-Temp Reheat | Increased Toughness |

| Annealing | Soften for Machining | Very Slow Cooling | Maximum Ductility |

| Normalizing | Refine Grain Structure | Air Cooling | Uniform Strength & Ductility |

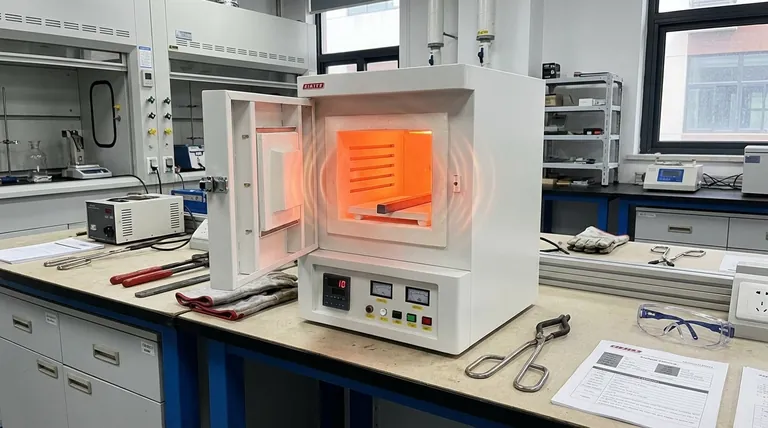

Need precise heat treatment for your lab materials? The right furnace is critical for achieving consistent results in hardening, tempering, annealing, and normalizing. KINTEK specializes in high-performance lab furnaces and equipment, delivering the exact temperature control and uniform heating your steel samples require. Contact our experts today to find the perfect heat treatment solution for your laboratory's needs.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the temperature of the arc in an electric arc furnace? Harnessing Heat Hotter Than the Sun

- What is the process of vacuum heat treatment? Achieve Superior Material Performance and Purity

- Why can't convection and conduction occur in vacuum? The Critical Role of Matter in Heat Transfer

- How the increased use of pyrolysis might affect the environment? Unlock a Circular Economy or Risk Pollution

- Can I melt aluminum on the stove? Why It's a Dangerous and Ineffective Method

- What is the temperature sintering of alumina? Unlock Superior Performance with 1500°C to 1700°C

- Does heat treatment affect strength? Master the Art of Metal Property Control

- What is the primary function of a high vacuum furnace in heat treating stainless steel? Precision Microstructural Control