At its core, the tempering process for steel is divided into four distinct stages, each occurring within a specific temperature range and causing unique changes to the steel's internal microstructure. These stages are not just arbitrary temperature milestones; they represent a predictable sequence of metallurgical transformations that trade the extreme hardness of quenched steel for much-needed toughness and ductility.

Tempering is best understood not as a single heating event, but as a controlled journey through four microstructural phases. The specific "stage" you stop at determines the final balance between hardness and toughness, allowing you to tailor the steel's properties to a precise engineering requirement.

Why Tempering is Necessary: From Brittleness to Toughness

To understand the stages of tempering, you must first understand the state of steel immediately after quenching. It is a material of extremes, which is both useful and dangerous.

The Starting Point: Quenched Martensite

When steel is heated to a high temperature and then cooled rapidly (quenched), its atomic structure is trapped in a configuration called martensite.

This martensitic structure is extremely hard and very brittle, like glass. While high hardness is good for wear resistance, the brittleness makes the steel useless for most applications, as it would shatter under impact or stress.

The Goal: Trading Hardness for Toughness

Tempering is the controlled process of reheating this brittle martensitic steel to a temperature below its transformation point.

This reheating gives the trapped carbon atoms just enough energy to move and rearrange themselves into more stable structures. This process relieves internal stresses and systematically reduces hardness while dramatically increasing toughness—the ability to absorb energy and deform without fracturing.

The Four Stages of Tempering Explained

Each stage is defined by a temperature range and a key microstructural event. The temperatures are approximate and can shift based on the steel's specific alloy content.

Stage 1 (Up to 200°C / 400°F): Initial Stress Relief

In this first stage, the highly strained martensite structure begins to relax. Extremely fine particles of a carbide, known as epsilon (ε) carbide, begin to precipitate.

This causes a slight reduction in hardness but provides the first critical step in relieving the internal stresses created during quenching. The improvement in toughness is minimal.

Stage 2 (200°C - 300°C / 400°F - 570°F): Transformation of Retained Austenite

After quenching, not all of the steel's structure may have transformed into martensite. Some of the original high-temperature structure, austenite, can be retained.

In this temperature range, this retained austenite decomposes into a structure similar to bainite. This transformation can paradoxically cause a slight increase in hardness and a decrease in toughness, an often undesirable effect.

Stage 3 (250°C - 500°C / 480°F - 930°F): Cementite Formation and Toughness Gain

This is the most critical and common tempering range for a vast number of applications. The unstable epsilon carbides from Stage 1 are replaced by stable particles of cementite (Fe₃C).

The martensitic structure fully breaks down into a tough composite of ferrite and finely dispersed cementite. This stage sees a significant drop in hardness but a dramatic increase in toughness and ductility. The microstructure formed here is historically known as troostite.

Stage 4 (Above 500°C / 930°F): Spheroidization and Maximum Ductility

At these higher tempering temperatures, the cementite particles begin to coarsen and change from a plate-like or rod-like shape into small spheres, a process called spheroidization.

This results in the lowest hardness and strength but the highest ductility and toughness. This highly ductile structure, historically called sorbite, is ideal for applications that require extreme shock resistance over absolute hardness.

Understanding the Trade-offs and Pitfalls

While tempering is a solution, it has complexities that can trap the unwary. Understanding these phenomena is key to achieving consistent results.

Tempered Martensite Embrittlement (TME)

Also known as "blue brittleness," this phenomenon occurs when tempering in the range of Stage 2 (roughly 250°C - 400°C / 480°F - 750°F).

The precipitation of carbides along specific planes in the microstructure leads to a significant loss of toughness. For this reason, this temperature range is almost always avoided for components that require impact resistance.

The Hardness vs. Toughness Curve

The relationship is an inverse curve. As you increase tempering temperature, hardness follows a downward slope while toughness follows an upward slope.

The goal of the engineer is to find the precise point on that curve that delivers the optimal combination of properties required for the specific application.

Selecting the Right Tempering Stage for Your Goal

Your choice of tempering temperature is a deliberate engineering decision based entirely on the intended use of the final part.

- If your primary focus is maximum hardness and wear resistance (e.g., cutting tools, files): You will use a low-temperature temper within Stage 1 to relieve stress without significantly sacrificing hardness.

- If your primary focus is a balance of high strength and good toughness (e.g., springs, shafts, structural bolts): You will temper squarely in Stage 3 to develop a strong and resilient troostitic structure.

- If your primary focus is maximum toughness and ductility (e.g., components needing to withstand severe impact): You will use a high-temperature temper in Stage 4 to achieve a soft and highly formable spherodized structure.

By understanding these stages, you move from simply following a recipe to making informed decisions that precisely control the final performance of the steel.

Summary Table:

| Stage | Temperature Range | Key Microstructural Change | Primary Outcome |

|---|---|---|---|

| Stage 1 | Up to 200°C (400°F) | Precipitation of epsilon carbide | Initial stress relief, slight hardness reduction |

| Stage 2 | 200°C - 300°C (400°F - 570°F) | Decomposition of retained austenite | Potential for embrittlement (TME) |

| Stage 3 | 250°C - 500°C (480°F - 930°F) | Formation of stable cementite (Fe₃C) | Significant toughness gain, ideal strength/toughness balance |

| Stage 4 | Above 500°C (930°F) | Spheroidization of cementite | Maximum ductility and impact resistance |

Ready to achieve the perfect balance of hardness and toughness in your steel?

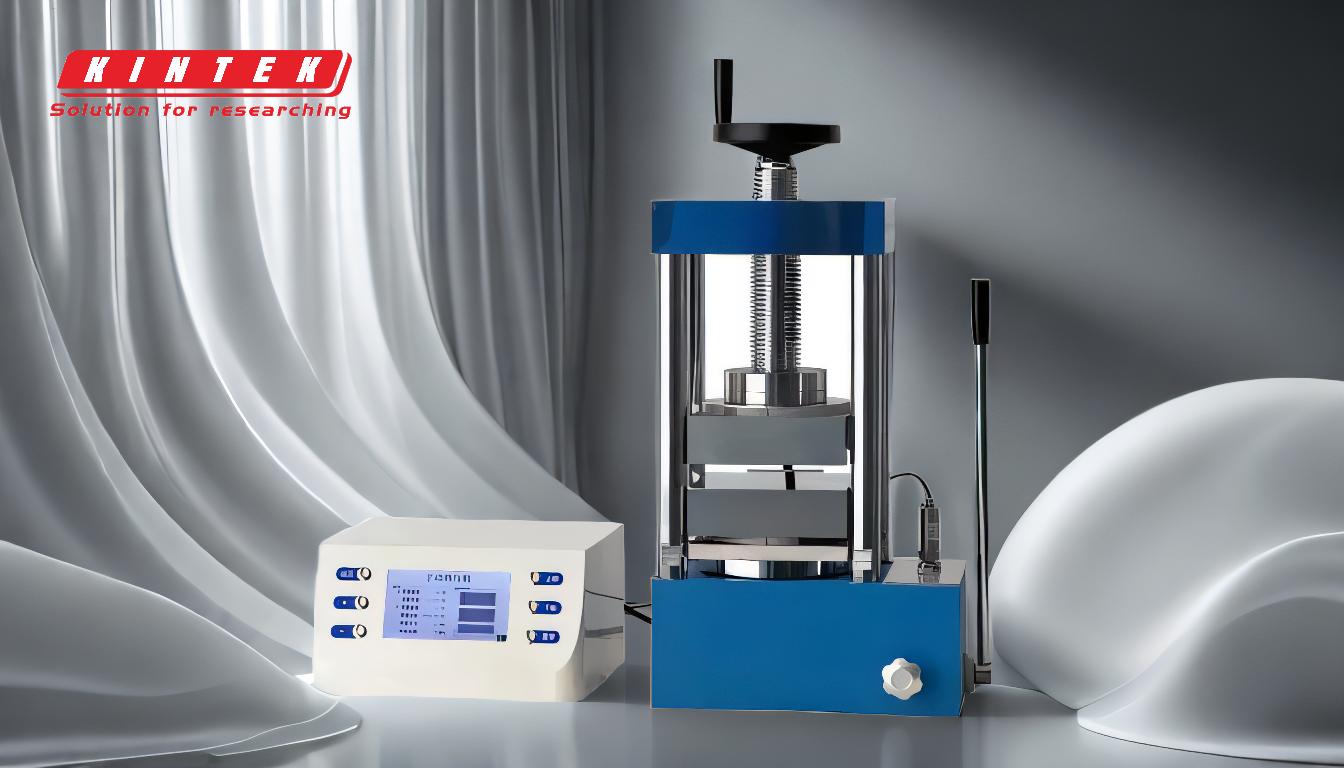

At KINTEK, we specialize in providing the precise laboratory furnaces and thermal processing equipment you need to execute controlled tempering processes. Whether you're developing cutting tools that require Stage 1 tempering or impact-resistant components needing Stage 4 treatment, our solutions deliver the accuracy and reliability essential for repeatable results.

Let our experts help you select the right equipment for your specific metallurgical challenges. Contact KINTALK today to discuss your laboratory's heat treatment needs.

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- What is the principle of vacuum heat treatment? Achieve Superior Material Properties with Total Control

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What are the disadvantages of vacuum heat treatment? High Costs and Technical Limitations Explained

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials